Everything that you wanted to know about polymer floors: analysis of the nuances of bulk technology

Bulk polymer floors are also called “liquid linoleum” - they are so comfortable to use. This is a new word in interior design, and just the same find for industrial premises. They give any interior extra visual volume due to its soft shine and seamless surface. Minimal shrinkage, high elasticity and modern aesthetics - these are the qualities due to which polymer floors are gaining more and more popularity in the CIS countries, and abroad they have long been at the number one market.

Content

Polymer floor: fashion or practicality?

There are many types of polymer flooring today: for every taste, style and idea. And in composition they are divided into:

- Polyurethane The floor has a good performance and can be laid independently both in the technical room and in a residential building.

- Epoxy-urethane. Such a coating is especially resistant to abrasion and is indispensable for significant pedestrian and transport loads: workshops, corridors and warehouses. True, the price is quite high.

- Methyl methacrylate. When laying such a floor, it is necessary to strictly observe the technology of the process, but after 2 hours after drying, you can walk on it. It is hardy and tolerates any weather in the open.

- Cement-Polyurethane coatings are used mainly to create floors with heavy duty: high temperature, exposure to aggressive chemicals and hot steam. It is this floor that most effectively protects the concrete base from destruction, which is why they are most often ordered for car service premises.

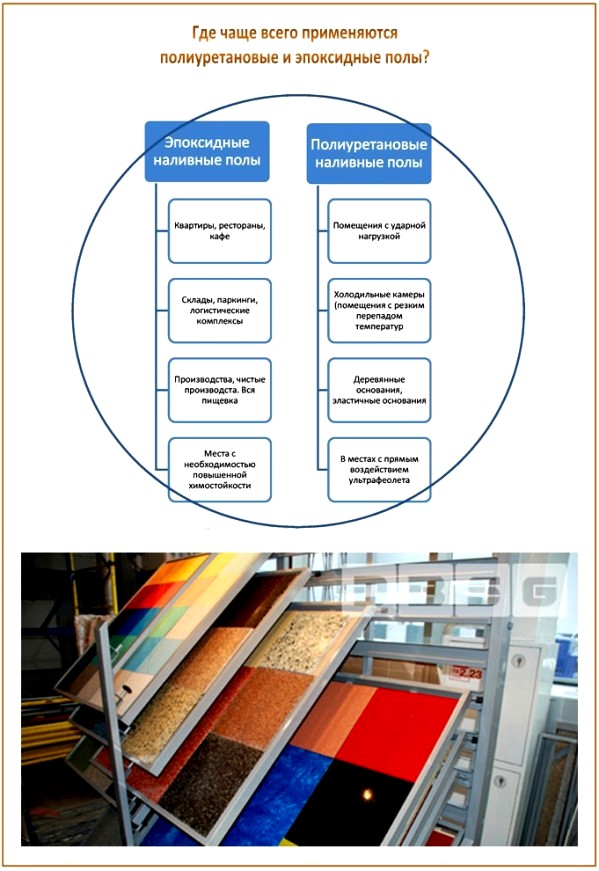

Of course, epoxy and polyurethane floors are more popular today due to their coating thickness: from 0.5 mm to 6 mm. Let's compare these two types of sex. So, epoxy are obtained much harder, they are cheaper, but they are laid with a layer of up to 5 mm, while polyurethane is enough 3 mm. And polyurethane floors are more scratch resistant than epoxy floors.

Bulk floor: revealing technology secrets

So what is a polymer floor? All the compounds that are used today, experts are divided into two main groups: polymer and mineral. The latter are a mixture of cement, modifiers and fillers, on which the rate of falling asleep depends. These are self-leveling floors that easily form a smooth finish due to low connectivity. Polymer floors are used as a continuous topcoat, which may be depending on the mixture itself and fillers.

Bulk polymer floor is made by modern manufacturers of epoxy resins or polyurethane. Initially, this beauty was used only in industrial workshops, but even residents of apartments like dustlessness, the absence of flooring seams and the possibility of unlimited decoration.

For the bathroom, the polymer floor is absolutely ideal. Due to the absence of seams, moisture will not penetrate beneath it, and to the touch this coating is as pleasant and warm as linoleum, but not so soft.Another significant plus for the bathroom: polymer floors are not prone to mold or mildew.

Interestingly, even the most glossy at first glance bulk floors still have a valuable anti-slip property. That is why today even in pools they refuse tile, replacing it with a colored and fashionable polymer floor. And recently, they want to see such floors in the bedroom, in the nursery, and even in the office. After all, polymers have simply amazing qualities, and due to the fact that they are the main components of the bulk floor, any design idea now has the right to life.

Even stunning 3D effects, for which today airbrushes are often invited, who just need to make a few extra touches to the same fish under water to make them appear bright and vibrant.

Coating specifications

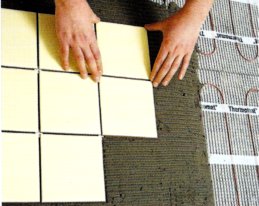

To the touch, such a floor is warmer than tiles and even softer than linoleum, and it can easily be combined with a warm floor system. Plus lots of nice benefits:

- High wear resistance;

- Lack of traumatic slip;

- Resistance to aggressive household chemicals;

- Absolute environmental friendliness - all components of the solution are non-toxic;

- Perfectly flat surface for any subsequent finish;

- Hygiene and easy cleaning;

- The ability to apply any image;

- Fire safety and a high level of waterproofing;

- The complete absence of seams and joints, where bacteria and dirt do not gather;

- And polymer floors are so resistant to low temperatures that they are even used as a base for large freezers.

The resistance of the bulk polymer floor to the effects of temperature is amazing: it will not lose its properties in the range from -60 ° C to + 90 ° C. And even on the verge of these values, the floor will neither ignite, nor smoke, nor emit any toxins. And all because the polymers comply with international standards.

And also, unlike concrete screed, these floors never emit dust or life-threatening compounds. In addition, interesting images are also applied to it: 3D pictures, small details and much more. We can say that polymer floors are a real field for the imagination of modern designers.

But polymer floors have some disadvantages that you should know:

- Sufficiently large amount of work and its completion time

- The high cost of materials used

- High cost per estimate if you hire a construction team

And keep this in mind in advance: if you ever want to change the flooring, it will be extremely difficult to tear off the bulk floor - it’s much easier to fill it with a new layer or just lay the same parquet or carpet. In general, that's all the cons.

What does the market offer?

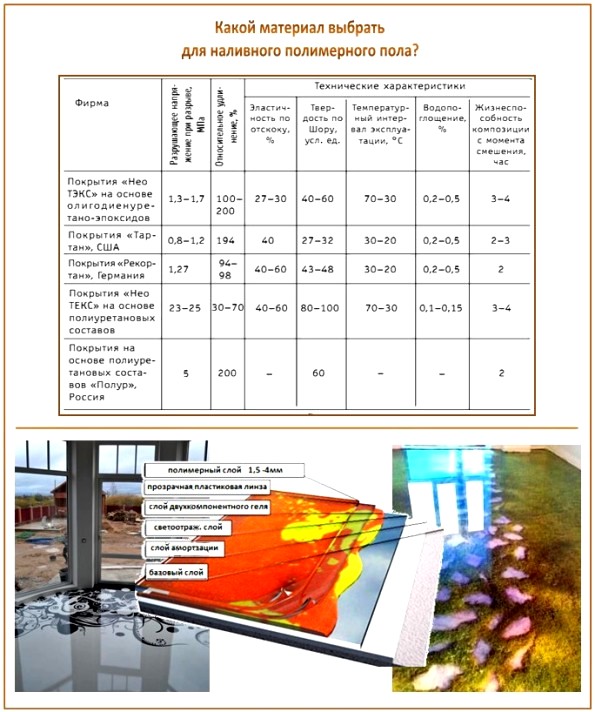

The bulk floors have a wide range of colors and patterns - much wider than even the tiles. Prices for polymer coatings are quite different: they depend on the design, the polymers used and the brand. Also, with a strong mechanical effect on the floor in the room, they prefer the polyurethane version, since the epoxy ones are less elastic. But for a constant static load - just right.

As for the brand, so far the best reviews can be heard about the Gipcreet Thermafloor filling field. It is a light polymer solution that never cracks. No less popular today is the brand of bulk floor "Elacor PU". This mixture has a good hardener and color base that mix right before use. As a result, the floor is resistant to stress, dampness and the active use of chemicals.

Also, good reviews can be heard about Praspan and Proplan, SIKA and Hyperdesmo. And for the most complex projects, they often choose RINOL, an Italian company, which today is considered the world leader in bulk coating systems. Such floors are not replaceable for those rooms where special or increased requirements are imposed:

- Parking;

- Operating;

- Supermarkets

- Public premises;

- Transformer substations.

The environmental friendliness, durability and resistance to ultraviolet of the final coating really depend on the quality of the materials used. If you hire a brigade to fill the polymer floor, it will not be out of place to ask them about the availability of certificates.

Expensive is not the polymer floor itself, but its laying. Construction companies really often inflate prices for such services, which they often admit themselves. That is why, if you learn to fill such a coating yourself, then a modern bulk floor will not be a luxury for you, but a great option for updating a house. And over time, thanks to an impressive period of operation, the polymer floor will pay off at least twice.

DIY filling - how realistic is it?

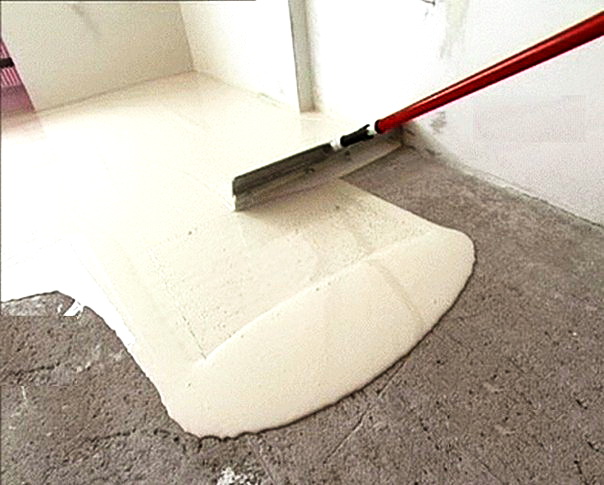

Absolutely real. After all, the bulk floor tightly mates with any base: tiles, concrete and even wood. The main thing is that it is clean, dried, even and fat-free. In total, the moisture content of the base should not exceed 5%.

So, after you put the mixture on the floor, it will spread and take on a perfectly horizontal level. Your task is only so that there are no air bubbles anywhere - and for this they use a studded roller.

And put any items to create 3D fashion floor It’s possible just at the finishing stage: put it on a thin layer of polymer varnish, and fill it all up again.

Read more in the articles:

How to care for the bulk floor?

And finally, it’s not difficult to take care of the bulk floor - as for parquet. Periodic it needs to be updated, covering with a protective varnish, and the rest of the time it’s enough wet or dry cleaning.

Polymer bulk floors are washed with special high-acid household chemicals. It must be applied to the floor surface for five to ten minutes, then thoroughly clean off the remaining polish and rinse the coating well, using as much water as possible. This is usually done using special equipment, but you can handle it yourself. If on the floor there are stains from tires or other complex dirt, then these places are covered with a detergent for deep cleaning for five minutes, and then cleaned.

In industrial premises, where there is a particularly strong mechanical load on the floor, dirt is clogged into invisible microcracks, and the coating becomes a little dull. Then modern high-pressure washing units are used, which easily knock out all the dirt and the renovated floor is varnished.

If the bulk polymer floor will often be washed with aggressive chemicals in the future (for example, in medical facilities), then it is protected from damage even at the stage of pouring - covering with a special protective polish using monom. And this polish needs to be updated every six months.

Also remember that polymer coatings are not designed for prolonged exposure to alkalis or acids of high concentration - and therefore detergents cannot be left on the surface for a long time. And another piece of advice: it is advisable to install rubber pads on furniture legs or work equipment - this way the floor will last longer.

So why, given the relatively low cost of the material and the understandable laying technology, do they take so much for such a job? It’s just that for our country such floors are to some extent still a novelty, and it’s always good to make money on new products. Try to do it yourself - the next step is to replace the floors in absolutely all other rooms!

2 comments