How to choose tile adhesive for a warm floor + analysis of the nuances of its application technology

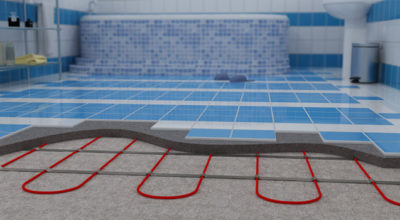

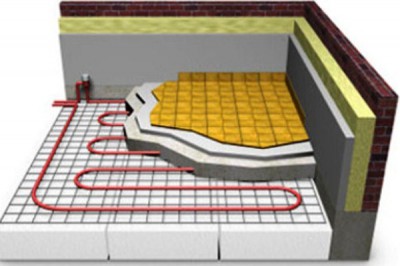

Ceramic floor tile is a material with a mass of undeniable priorities, but one significant drawback is its high thermal conductivity. Therefore, it is often laid on top of a water or electric heating system, called the “warm floor”. The technologies and schemes for gluing floor ceramics to the floor surface, including the heating system, are similar to the methods of its usual laying. However, there is a difference: you need to use a specific adhesive for a warm floor, otherwise the coating will last no more than three to four weeks.

Content

Why is special glue needed?

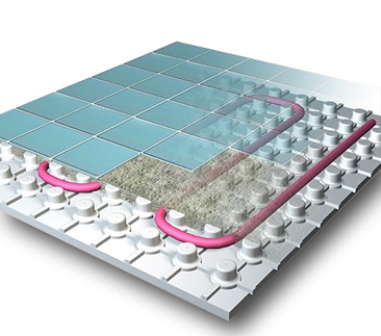

The operation of "warm floors" with any finishing surface implies a constant effect of temperature changes on the materials included in the puff structure. In the usual adhesive composition, linear expansions occur due to a rise in temperature, followed by a decrease in volume during cooling. The result of fluctuations is cracking, delamination of the ceramic coating elements, the appearance of air-filled voids under the tile layer. The floor covering will not only not “hold onto” the lined surface, but will also interfere with the passage of heat due to cavities filled with air.

Therefore, for the installation of a ceramic floor, designed to work together with a heating water or conductive circuit, a special binder composition is required, which:

- tolerates cyclic temperature changes without consequences,

- does not respond to the impact of critical temperatures (-30º; + 150º C);

- has elasticity, is easily applied to the surface being trimmed;

- creates strong adhesion with a rough surface and with floor ceramics;

- does not affect the inertia of heating the floor structure.

High consumer properties of elastic adhesive materials for laying stone, clinker, tile on a warm floor are achieved by introducing specific polymer modifiers. These plasticizers exclude the appearance of cracks due to expansion and subsequent compression of the binder.

The adhesive is tested by the manufacturer, on the basis of studies in the labeling, the number of cycles of temperature fluctuations that the composition transfers without destroying the structure, and other characteristics are indicated.

Factors affecting the choice of adhesive

Regardless of the design features of the “warm floor” system, before laying the tiles, the floor plane is leveled to the parameters regulated by the building codes (2 mm of the difference in elevation should be distributed to a maximum of 2 m2) That is, before gluing the tiles, alignment is necessarily performed with a cement or polymer screed. When choosing tile adhesive for a warm floor, it is necessary to pay attention to the base materials listed by the manufacturer that are compatible with this adhesive composition.

You can learn more about how to lay ceramic tiles yourself from the article:https://floor.expertexpro.com/en/pol-pokritiya/plitka/ukladka-napolnoj-kafelnoj-plitki-svoimi-rukami.html.

Attention. The device of the film infrared floor, regardless of which plant is manufactured, is not made directly into the screed; glue cannot be applied to the surface of the film heating system. The alkaline environment of the components of the adhesive composition causes the destruction of the structural bonds of the film floor and damage to the heating system. Therefore, leveling sheets of DSP or glass-magnetic material are laid on top of the film, after which a screed is made or a layer of glue is applied.

You can align the floor with the heating equipment for mounting the tiles using an isolon or drywall, but this option will significantly reduce the distance between the ceiling surface and the floor plane.

Elastic Adhesive Technology

Most often, for gluing floor ceramics laid on top of a heating system, compositions with an aluminate cement base or cement marked with the designation M500 are used. The tile floor adhesive enriched with plasticizers will not have a damaging effect on the underfloor heating. The entire layered structure will stably resist the tests that fell to its lot without cracks and without the formation of voids under the ceramic floor covering.

Adhesive materials made on the basis of epoxy resins are allowed. Resistant to temperature fluctuations and high temperature effects, epoxy compounds are distinguished by excellent adhesion to ceramics and concrete.

Which is better: water or electric underfloor heating? We will deal with this issue in the material:https://floor.expertexpro.com/en/tepliy-pol/kakoy-pol-luchshe-vodyanoy-ili-elektricheskiy.html.

Most elastic adhesive materials are supplemented with modifying components that allow you to adjust the position of the laid tiles within 10-15-20 minutes after fixing in the designed place. During this period, the adhesive retains the ability of the manufacturer to adhere to the ceramics and the base to be finished, embedded in the composition formula.

Adhesive mixture preparation

Material intended for gluing ceramics to a rough surface located above a warm floor is most often supplied in the form of a dry mixture of 25 kg packaged in waterproof bags. This composition requires strict adherence to the instructions attached to the product, describing the preparation of the mixture.

Attention. The temperature and humidity conditions specified by the adhesive manufacturer must be strictly observed.

The strict observance of proportions, mixing rules, sequences and waiting periods for the ripening of the mixture ensures the formation of the properties necessary for durable fastening of the coating. The shelf life of the adhesive mass required for styling qualities must also be observed. Usually, after three hours, the finished mixture loses its binding properties, that is, you need to cook such a volume of glue that will be consumed before the expiration of the time specified by the manufacturer. There are compounds that can be mixed again when signs of premature consistency change are manifested.

We will tell you about the features of installation technologies for various types of underfloor heating in a special material on the site:https://floor.expertexpro.com/en/tepliy-pol/montazh-teplogo-pola-svoimi-rukami-video.html.

Application technology

The methods for applying glue that works with heating equipment are no different from well-developed building standards:

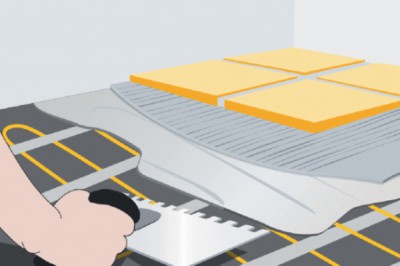

- On the leveled surface cleared of dirt, grease-containing and paints and varnishes, glue is applied with a grater, treating the area with the composition, which the contractor can finish before the curing of the binder mixture.

- The glue is “combed” with a notched trowel. The square shape of the teeth of this tool is recommended.The size of the teeth depends on the caliber of the material chosen for finishing: the larger the dimensions of the elements of floor ceramics, the larger the teeth. They form a kind of grooves that optimize adhesion.

- The formation of technological seams is a mandatory requirement when installing tiles on any surface. They are necessary so that during linear expansion resulting from heating, the tiled floor does not deform, does not reel with a "house", and does not crack. To create beautiful even seams, plastic crosses are used.

- Grouting It is carried out in a day after installation of a tile. The operation of the system underfloor heating can only begin after the completion of the hardening process, the period of which is specified by the manufacturer.

Note. The amount of glue applied to the base depends not only on the speed and skill of the performer, but also on the dimensions of the elements of the ceramic floor. If the size of the side of the elements does not exceed 30 cm, it is better to process no more than 0.7 m2 area. Finishers laying large floor tiles or porcelain tiles can apply glue to a 0.8-1.0 m area2.

In order to install the underfloor heating system under tile adhesive followed by ceramic flooring, special compositions are needed, without which the multilayer system will not last long. Properly selected material will provide wear resistance and will not create obstacles to the passage of thermal energy.

1 comment