Bulk polyurethane floors: an overview of pouring methods and design tips

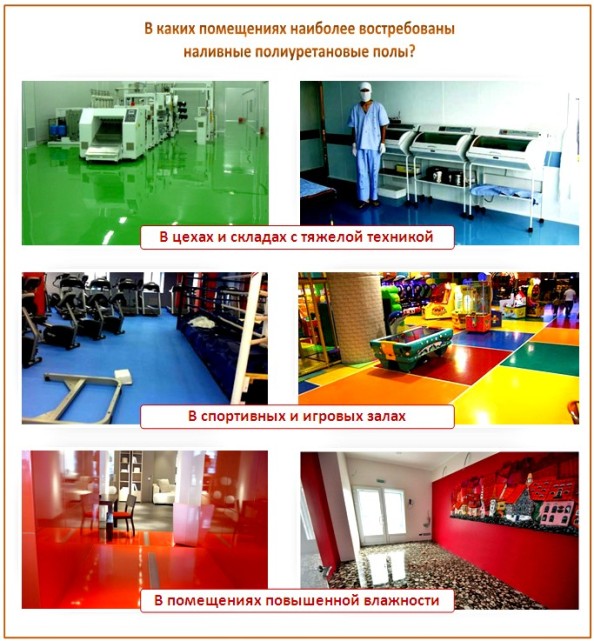

Most often, you can find bulk polyurethane floors in retail and exhibition halls, swimming pools, retail and warehouse facilities, medical facilities, and less often in residential apartments. Although just in the house such floors are an excellent ready-made solution for the kitchen, bathrooms and hallway, where moisture, sharp hairpins and falling sharp objects are quite common. What is the composition of such a coating and what are its advantages? Now we will understand everything in detail.

Such floors are not only a chic design solution, but also:

- Amazing durability

- High resistance to any mechanical stress.

- Perfectly even base for further experiments

- Hygiene and utmost ease of cleaning

- The complete absence of dust or dirt, as from a concrete screed

- Originality and exclusivity of the entire interior design

Polyurethane floors also withstand severe temperature extremes. That's why they are often made where the room does not have a roof, where vibration is constant and loads can be attributed to hard abrasive. This type of floor is especially durable: with its insignificant thickness, which does not always reach 3 mm, after just three days you can begin to haul almost tractors on it.

Another important advantage of the polymer floor, which I would like to note separately, is the ease of repair. In a production workshop or in a car repair shop, situations are quite common when a sufficiently heavy and sharp object falls. For a tile or laminate, this is a serious restoration work, while the polymer floor in a damaged place is enough just to sand and varnish. And, surprisingly, even the thinnest heels can not damage such a coating.

Content

Types and composition of a modern polyurethane floor

Polyurethane floors today are used in two types:

- Single layer, or thin layer. They are rarely thicker than 0.5 mm and are designed for rooms with a low level of load. They are not difficult to scratch, but they carry light strokes and modern household chemicals for residential buildings without problems. Although updating such floors is also much easier than others.

- Two-component, or highly filled. The thickness of these is much more than the previous ones - up to 2.5 mm. This coating is designed for intense loads, and you can wash them with any detergents. Two-component polyurethane floors are resistant to sudden changes in temperature, are stable and serve at least 10 years, even in a car workshop.

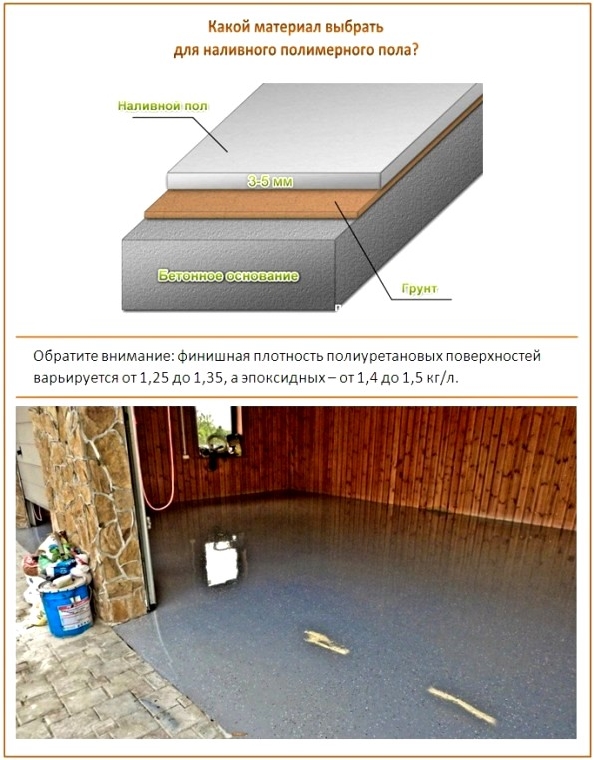

In the context of the bulk polyurethane coating will have three layers:

- The bottom, which is an impregnation of a uniform composition and low viscosity, which serves as the basis for pouring.

- Medium, namely a two-component polyurethane coating with high elasticity and adhesion.

- The upper anti-corrosion layer, due to which the floor is endowed with high resistance to chemical and mechanical influences.

Here is the diagram:

If you are unable to choose which self-leveling floor is best for your room, then in the next article we will talk about the types of self-leveling mixtures:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/kakoj-nalivnoj-pol-luchshe.html.

Subtleties of pouring polyurethane floor

The application of a polyurethane floor is somewhat similar to painting the floor with oil paint. Even more, polyurethane spreads across the floor like water - very quickly, and easily fills small cracks and bumps. At the same time, the wear resistance of this material is impressive: it wears out much more slowly than steel, which is why automobile brake pads are also made from polyurethane compounds today.

A polyurethane floor, in principle, can be poured onto almost any dry and even foundation. But, if you do everything in good faith, then a concrete screed will not be superfluous.

On fresh concrete screed

So, if you are going to make a new one - then wait a month, and you can already work on the polyurethane floor. This is necessary so that the moisture content of the base is not more than 4%. The strength of concrete, take at least M200 - this is important.

On an old concrete base

But how to work with the old screed? The most important thing is to correct its irregularities and clean it well. Be sure to close up cracks and other defects, and then carefully smooth the base itself - you can even use self-leveling mixtures.

Read more about how to level the floor with self-leveling mixtures, how to choose the necessary composition and complete the whole range of works, read in the article:https://floor.expertexpro.com/en/viravniv-stazhka/vyravnivanie-pola-samovyravnivayushhejsya-smesyu.html.

If possible, prepare as horizontal a base as possible so that it does not have to be leveled. If you nevertheless align, then a cement-sand screed.

By the way, many people care about the question of how to replace a rather complicated process. surface grinding. So, exactly two hours before applying the primer, vacuum the base. When the first coat dries, apply the second and sprinkle the floor with hot quartz sand. When everything has hardened, vacuum the remaining sand again.

How to fill in such a floor yourself?

Apply the finished compound to the base with a spatula and squeegee, and then walk along the surface with a needle roller. When working with a polyurethane floor, between the filling of the layers you need to wait at least twenty hours. That is why this process is also called polymerization - at this time, the composition must be carefully protected from moisture and the best solar. Only a day after the completion of work it will be possible to walk on the new coating, but to return the premises to the previous mode of life - only after a week.

Avoid Common Mistakes

Here are some important mistakes to avoid when making a polyurethane floor:

- If the base is poorly dried before pouring, leave oil stains or do not remove dust - the floor will be removed by layers with some effort. If you notice this over the entire coating, you will have to dismantle it; if only in places, just re-fill them. If you were inaccurate and somewhere trash fell on the cover, remove it after hardening the composition with ordinary sandpaper.

- Particularly balanced you need to approach the issue of the amount of water in the mixture. If it is not enough, lumps are formed; if there is a lot of it, the quality and strength of the polymer material will deteriorate.

- Are you also interested in learning about the most expensive mistake when filling a polyurethane floor? So, in hot weather, after mixing the mixture, you take literally a minute of rest (distracted, for example), then unexpectedly for yourself you can find a tightly frozen mass in a bucket, naturally, very expensive. Yes, according to the instructions, such a composition freezes no later than 10-20 minutes, but in the heat it can catch unexpectedly quickly. So in due time not a single novice master came across. Therefore, at a similar temperature, it is better not to work. And with a more optimal one, also try to pour the mixture immediately into the application zone immediately after kneading.

By the way, if you fill in a polyurethane floor, you will smell quite unpleasant, but it will completely disappear after 2 hours.

Decorative polyurethane floors: it's easy!

Decorated bulk floors - today are already integral to the corporate design of modern institutions. And at the same time they are amazingly strong and durable. That is why they began to equip them with pleasure in modern apartments.

The simplest ornament on bulk floors can be done like this: fill in the basic white color, and on it we draw gray, blue or red. For example, hieroglyphs with a specific meaning look especially effective.

But many are interested in: how are two or three different colors used in the coating, moreover, in the form of arcs or geometric shapes? And how do they join? In fact, the technology is quite simple: first the colored polymer is poured as a background, the next layer is drawn on it, and then the transparent layer. Just do not pierce the drawing itself with a roller - a protective layer on top is enough for it.

The third option: a pre-prepared picture is printed in a printing house, glued to the base and filled with a transparent polymer. And here there is one point: if it suddenly turned out that the gloss somewhat interferes with the overall effect of the floor, you can additionally apply another layer - matting polyurethane varnish.

Important is not only the choice of the material itself, but also the correct calculation of the required amount of the mixture for the bulk floor. To exclude the acquisition of costly surplus. Read about it in a special article on our website:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/nalivnoj-pol-rasxod-smesi.html.

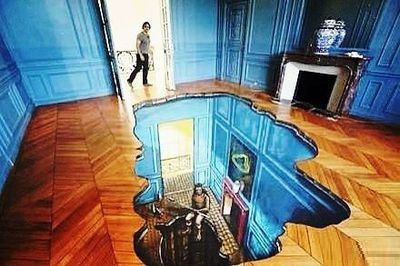

Photorealistic floors ZD

Thanks to the special design of the self-leveling floor, 3D art has penetrated into residential interiors: live landscapes, three-dimensional images, optical illusions. It all looks really amazing. In addition, right under the transparent layer of polyurethane varnish, you can easily lay out anything: coins, your personal photos and letters, beautiful fabric, shells, money and other pleasant things. And all this is the path to a truly exclusive design. In corporate buildings, company logos are applied to such floors, and the color and idea necessarily overlap with the walls.

The most common type of decorative floors, which are also conditionally classified as ZD, are photorealistic images in which the principle of airbrushing is involved. Let us explain: this is a special art technique that uses compressed air as a tool. Thanks to the thin application of paint and smooth spraying, the decorative effects are amazing: volumetric, smooth color transitions, imitation of a rough texture and amazing photographic realism. Those. The procedure for creating a polymer layer itself is almost no different from the usual one, only here an additional 3D image is used at the finish. The only moment: as a rough layer, use precisely polymer mixtures, but not just cement-sand screed.

By the way, among polyurethane bulk floors there is still one absolutely transparent, it is more expensive than epoxy, but it will not deteriorate with time from ultraviolet radiation. Why polyurethane floor for three-dimensional images? Because it is more durable, it can’t be squeezed by furniture (and therefore not distort the picture), and it, unlike epoxy, will not turn yellow over the years.

The process itself looks quite simple:

- Step 1. The prepared base is well primed with a composition that we will then use for the finish coating. Dilute it in a 2: 1 ratio with the 646th solvent.

- Step 2. After a day, stick the finished film or fabric there, smooth it well from the middle to the edges. If you used the fabric, allow time for the adhesive to dry.

- Step 3. Fill with the final polymer layer: EkoteX, Elacor-ED, or Taping Floor 205.

- Step 4. Now fill with a protective varnish: “Elacor-PU Lux”, “Multiprotect” or LEVL Coat 252.

In total, it will take you about 1-3 kg of polymer varnish per square meter.

Important tips for choosing the design of this floor

We note immediately an important point: any grotesque style in interior design can be quite tiring. And therefore, if you do not want to regret such a seriously done work and considerable money spent in a year, follow our tips:

- Make bright and unusual 3D floors where your guests are often and less often - households. Just to not get tired.

- Grinning animals and attacking predators on weekdays will not give you a good mood. Yes, in the mouth of a huge shark on the floor it is interesting to take pictures and scare your friends, but on ordinary days a constant scene from a “shark tornado” will affect your subconscious. The result - bad dreams and anxiety do not understand why.

- In the nursery, it is better to abandon such sexes - this is too bright an irritant for the psyche of the child.

- The smaller the illusory-volume 3D element in the floor decor - the better. This is a truly grand accent of interior design, and by all laws of style it should not be much. A bed on a huge waterfall in life looks ridiculous.

- Put furniture in a room with such a grotesque coating of the “future”, and make walls and textiles plain.

But where really 3D design looks amazing, it’s the bathroom - the floor in it can really be made of fish and shells underwater alone. But do not forget - this is because the interior in the bathroom is usually minimalistic: mostly monotonous color and the absence of additional accessories. Funny dolphins and a girl underwater in a bathroom or pool can really please the eye for a long time. Here dynamics is an exception to the rule. In a bright living room, the effect may be slightly different. And therefore, if you are going to choose a picture for all rooms, make sure that everything is felt in harmony, and the eye is pleasant.

But lighting under a transparent polyurethane layer of the floor is not recommended to be installed (believe me, very, very many people come to this idea). For the reason that then replacing burned out fixtures will be extremely problematic. Although we have no doubt that in the near future enterprising manufacturers this problem will be successfully solved, and another new era will come in interior design!

3 comments