Leveling the floor with a self-leveling mixture: selection of the composition and execution of work

Quite a typical situation: the old concrete floor, a lot of potholes and chips, not a single smooth area. You can, of course, close every hole for half a life, and for long days wait until the seal is dry and the time comes for the main screed, which will take a month to dry. And you can start finishing in a few hours, using a new generation of mixtures - plastic quick-hardening compounds with a remarkable ability to spread. So they are called - self-leveling mixtures, which are also called levels for the floor.

The strength of a floor made on the basis of a self-leveling mixture significantly exceeds the strength of even a concrete screed. That is why it is possible to safely put absolutely any finishing coating on such a floor, which is called bulk, or even use the composition as a finishing touch (most self-leveling mixtures can be used for both purposes).

Content

Pros and cons of modern levels

They are easy to knead, easy to use: fill the dry mixture with water and pour this liquid paste onto the floor. It quickly fills all the potholes and creates a perfectly flat surface. And a lot of other advantages:

- Quick drying.

- The ability to move around the surface in just a few hours.

- Putting the topcoat is possible in a day.

- Even a beginner can cope with the device of the bulk floor.

- Hardness, high wear resistance, complete lack of shrinkage.

- The minimum layer thickness is only 5 mm, which is indispensable for rooms with a low ceiling.

And the main disadvantages of self-leveling mixtures for the floor, we will not hide:

- The need for thorough surface preparation: there should be no cracks or dust.

- To perform the bulk floor, experience and qualification are required, as dismantling a failed coating of this type is extremely difficult.

- High cost, considering how difficult it is to make such a floor.

- Health hazard when the mixture dries up: toxicity and flammability can go off the scale, and drops of the mixture that get on the skin sometimes cause burns.

In short, you need to use self-leveling mixtures wisely.

Scope of self-leveling mixtures

In addition to the main purpose, which we have already talked about, sometimes self-leveling mixtures are used for a narrower specific purpose: dust removal, primer, improving the structure of the treated surface, and the like. And the fact that self-leveling mixtures dry so quickly is a huge plus. Indeed, in a short time, cracks simply do not have time to appear, there is no shrinkage, and water droplets do not leak into the base.

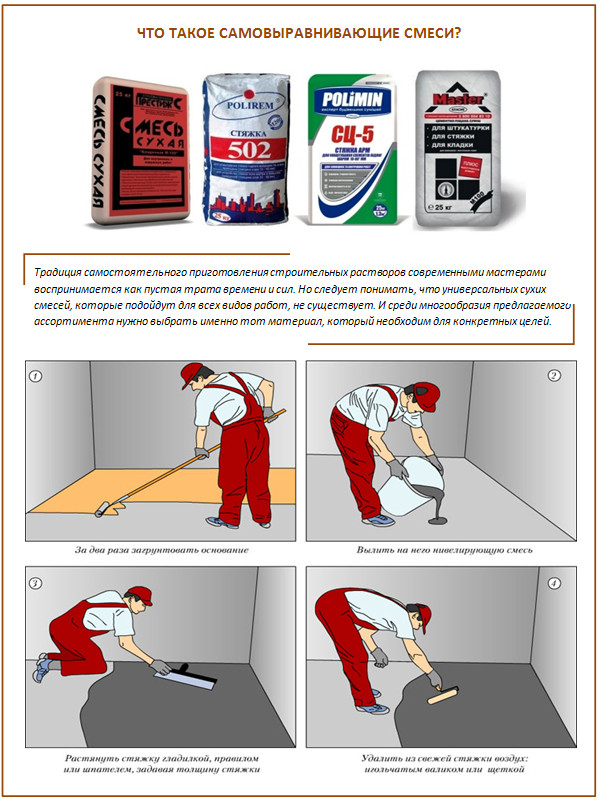

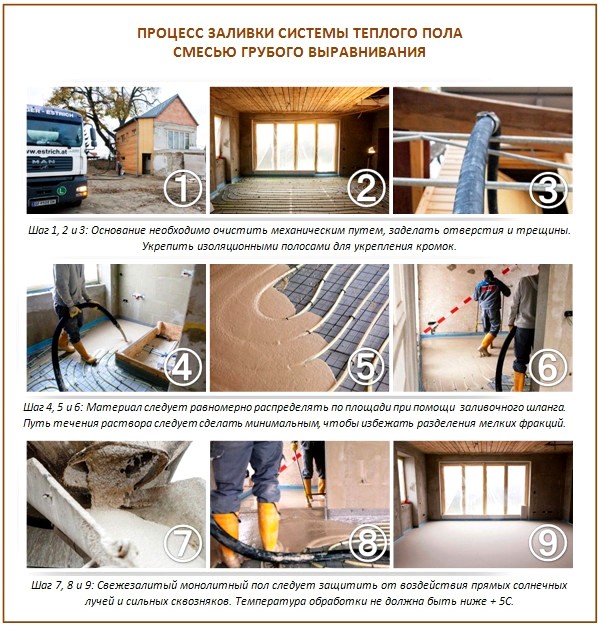

There is also such a thing as rough levelers - these are self-leveling mixtures with which you can arrange a rough floor, even with a screed of a warm floor:

What does the modern market offer?

All self-leveling mixtures contain special finely graded fillers up to 260 microns in size, and therefore the finish surface is much smoother than a conventional screed.The binder composition is usually gypsum or cement, and modifying polymers and mineral fillers are designed to improve the quality of the mixture itself, give elasticity, increase adhesion and the ability to self-level. And each manufacturer has such a recipe - his own, as well as a guaranteed end result.

So, with a serious difference in the height of the floor surface, the leveler is more suitable Valery Plus, with curvature from 0 to 22 mm, and Knauf nivellierestrichif the height difference is from 7 to 22 mm, which is a lot.

The Knauf company itself is today the leader in sales of such mixtures. It mainly produces them on the basis of high-strength gypsum with special modifying additives. Plus, fine quartz sand is added, which significantly improves the adhesion of the mixture to the base.

A little inferior to "Knauf" in quality mix "Vetonite". The screed, which is obtained according to such a recipe, has high technical characteristics, because there are already special additives in the composition. Thanks to them, it is easy enough to make an even base, and it quickly hardens. Their only significant minus is the impossibility of painting in the desired color and use as a finish on the floor. Especially if the fill is planned to be minimal in thickness, from 0 to 5 mm in total.

And finally, the company “closes the top three sales leaders”Horizon". The recipe is based on a cement-sand mixture. Such mixtures are especially in demand for the manufacture of underfloor heating screed, because the maximum possible thickness of the Horizont mixtures is 10 cm. And such floors can be treated with any paint and varnish materials, as, in principle, used as a finishing base.

For serious roughing, we advise you to use the company's products “Volma», Which are distinguished by good sound and heat insulation. Volma self-leveling mixtures can be used in absolutely all rooms without exception. Of course, except for those where the floor is generally in direct contact with water.

The fastest drying floor leveling compound is Ceresit CN-83. Walking on it is already possible 6 hours after the end of pouring.

To create a lightweight bulk floor, use a leveler IVSIL TERMOLITE. The consumption of this material is 3.5-4 kg / cm, due to which the mixture at large volumes comes out cheaper. This leveler is designed for thick-layer leveling of the base under the IVSIL finishing bulk floors. Its installation is more economical in time than polystyrene-based screeds, and the weight is quite low. The main advantage is heat and sound protection, with a minimum load on the foundation itself. For the device of floors of loggias and balconies - the very thing:

The P2 level self-leveling mix is ideal for leveling floors from gypsum boards, concrete or gypsum screeds, and old wooden floors - due to their increased ability to spread and self-smooth. Just imagine how fast the liquid can spill on a flat concrete floor and on old uneven wooden boards - there is a difference. That is why this mixture is indispensable for such bases - it manages to level out in 15 minutes, and in 3-5 hours it will be possible to lay linoleum or carpet, and in a day - a laminate. Its standard composition: gypsum, sand, resins and special modifying additives, which after hardening give a perfectly smooth surface a beige color. But for outdoor works or industrial buildings with high traffic, such a composition is not suitable.

But brand mixes Bolars valuable in that with their help it is possible to create not only durable surfaces, but also heat and sound insulated.

That is why it is so important to explore the specifics of each brand and each brand, because each product has its own characteristic properties.

Types of self-leveling mixtures

But the point is not which mixture is better or which is worse - for each base and for different purposes you need your own composition. Therefore, before buying such material, ask yourself questions:

- How dry will the room where you plan to level the floor?

- Will the floor have direct contact with water in the future? In simple terms, is it a kitchen, bathroom or another room?

- Will you have to wash such a floor with aggressive household chemicals in the future? Like in the kitchen, for example?

- Do you need a mixture for leveling or for finishing?

- On what basis will you make the bulk floor, and how much is it able to absorb moisture?

- What additional properties of the floor do you need: anti-skid, noise absorption, thermal insulation?

- Will there be additional decorative finishes for this floor?

From the answers to these questions and build on the choice of a particular self-leveling mixture. And there are not many species.

Option # 1 - based on cement

The cheapest are self-leveling dedusting mixtures, which additionally play the role of a good primer. The layer is very thin, and this floor serves only three years.

Cement-acrylic bulk floor. The main advantages:

- High adhesion, minimal shrinkage.

- Strength, the ability to operate as a screed.

- Absolutely any foundation is suitable, even wet.

- No cracks during use, good frost resistance.

- The ability to walk on this floor in a few hours.

And from the minuses:

- Moisture absorption, minimal or more noticeable, depending on additives.

- Acquisition of final strength in three weeks.

- An unattractive look that usually does not serve as a finishing floor, and expensive dyes to give color.

- Considerable expense - any layer can not be less than 5 mm.

Here's what the fill process looks like:

Cement compositions are much more expensive than gypsum, but gypsum can be used exclusively in dry rooms.

Option # 2 - gypsum based

Gypsum bulk floor - one of the most undemanding for leveling the base, has good thermal conductivity and is great for building a "warm floor" system. Another name for gypsum mixtures is anhydride.

Virtually no shrinkage, quick drying and environmental friendliness. But here, as for a polyurethane mixture, only a completely dry base is suitable.

Gypsum itself, as you know, the product is completely natural, does not dust, has excellent heat-insulating properties. Gypsum self-leveling mixtures are often used in order to get a sufficiently thick floor screed. After all, there are restrictions on the height of the screed: cement-sand can not be made more than 5 cm high, but gypsum - at least 10 cm.

As for brands, on a par with the well-known brand Knauf, domestic bulk floors are also in great demand "Miners". They are suitable for both manual and machine application. This brand is also appreciated for the fact that such a solution goes well through mortar hoses, without thickening and not getting stuck.

Self-leveling gypsum mixtures also dry longer. In addition, the strength of gypsum screed is much higher than that of cement.

Option # 3 - with epoxy resins

But the epoxy self-leveling mixture has serious disadvantages: increased abrasion of the surface, cracks from falling heavy objects and slippery from spilled liquid. It’s not suitable for the kitchen at all, as well as for the bathroom, but for chemical laboratories it’s what you need.

Option # 4 - from various polymers

Self-leveling polymer mixtures can be of very different compositions: from epoxy resins, polyurethane, methyl methane acrylate and the like. The main advantages of such a jellied floor:

- Particular surface durability that can easily withstand vibration, shock and severe stress. For a warehouse or industrial application - what you need.

- Resistance to sharp changes in temperature.

- Long service life, during which the coating does not lose its appearance.

- Water resistant and soundproof.

The only drawbacks are special demands on the dryness of the base and, of course, the price.

We apply a self-leveling mixture

It is not difficult to prepare self-leveling mixtures: just dissolve in water as described in the instructions for the mixture and mix thoroughly until smooth. Exactly five minutes later, mix again, and level it on the floor for 20-25 minutes.

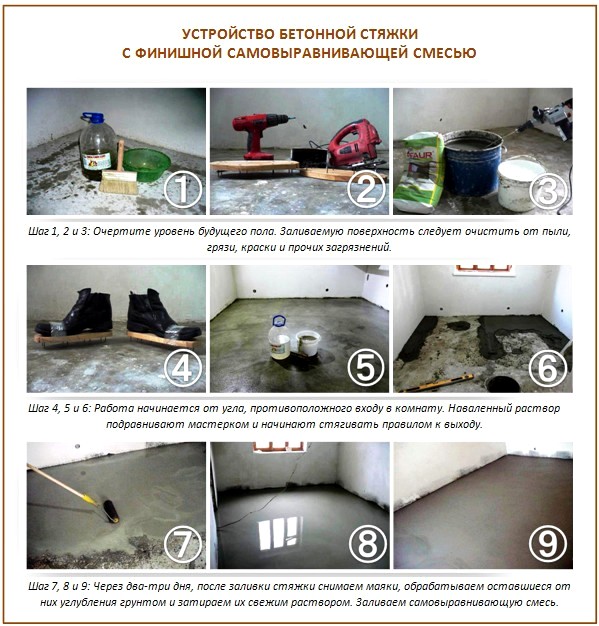

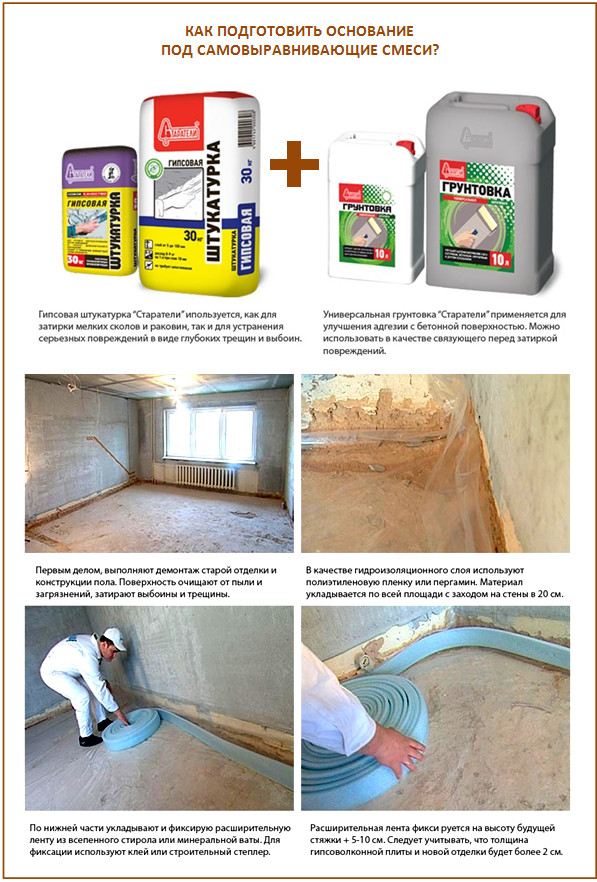

Before work, we always prepare the foundation: remove gypsum and cement milk, traces of varnish, wax and glue. The base should be clean and dry, without cracks, cracks and dust. It is necessary to level the floor with such compounds in a temperature regime of 10-30 ° C.

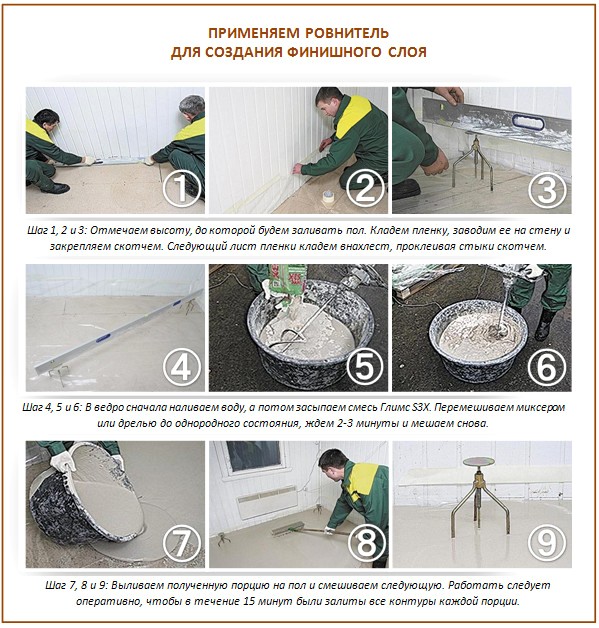

Further, the work process looks like this:

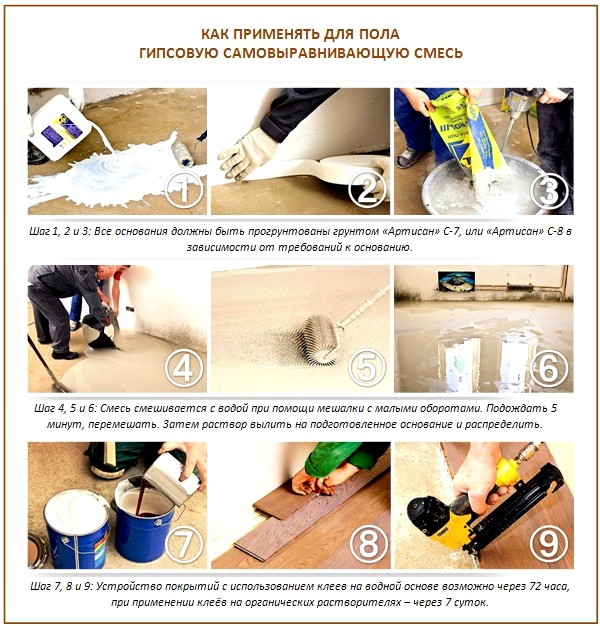

- Step 1. Grounding. If you will fill in the mineral base - primer with PRIM-S, wood - PRIM-PARQUET.

- Step 2. Knead the solution. To do this, fill the mixture with water - 6 liters per 25 kg of the mixture (just a bag), knead well and get a fairly liquid paste without sediment or signs of delamination.

- Step 3. Apply the mixture: on a wooden base - 5-20 mm, on all others - 2-20 mm. Those. the difference is only in the minimum allowed screed thickness.

- Step 4. We roll with a needle roller from the bubbles.

- Step 5. We are waiting for drying.

Illustrative example:

Neither grinding, nor additional leveling, such a floor already requires. It is only important that the freshly flooded floors do not dry out the first two days. They must be protected from direct sunlight, drafts and thermal devices.

If you need to level a sufficiently large area with this method, do not risk preparing a lot of the mixture - if you do not have time to pour it out, level it and go with a roller, then the residue will simply harden directly in the bucket. Therefore, it is better to divide the area into separate sections and work with each separately. Do not worry about the evenness of such a base - self-leveling mixtures practically do not shrink, and therefore there will not be any differences between the dried mixture and freshly poured.

MORE: if you poured floors larger than 20 m2then be sure to make expansion joints within three days.

But on a wooden floor and on plywood, such mixtures are not used. Although the bulk floor can be done on an insulating dividing base - for example, on a dense plastic film.

That's all! The technology of using self-leveling mixtures is quite simple and accessible to anyone.

6 comments