Soundproofing the floor in the apartment: selection of materials + floating floor device

One of the drawbacks of multi-storey buildings is the noise, which is everywhere. Penetrating into the apartment, it can cause irritation, disturbance to sleep or concentrated work. You can, of course, originalize and buy earplugs, but this situation will not fundamentally improve the situation. The most effective way is to perform noise isolation.

Since sounds most often pass through floors, in addition to walls, great attention should be paid to the floor. Moreover, the soundproofing of the floor in the apartment is quite a doable task.

Sound insulation implementation methods

One of the easiest ways by which you can significantly reduce the noise level - "soft floor". Carpet, linoleum on a foam or felt basis can be easily and quickly installed if necessary, for example, soundproofing of a wooden floor, they are quite effective, but they also have a number of disadvantages: one of them is not suitable for installation in “wet” areas.

Another way - the use of various kinds of soundproof gaskets when laying laminate flooring, hard linoleum. Soundproofing the floor under the laminate should consist of a substrate that has a high noise absorption, is optimally hygroscopic and is able to ensure its ideal installation. Often, foamed polyethylene or roll cork is used for these purposes, fibrous materials are also effective. Of great importance is the sound absorption coefficient. The higher it is, the better the result, and the thinner the substrate itself can be.

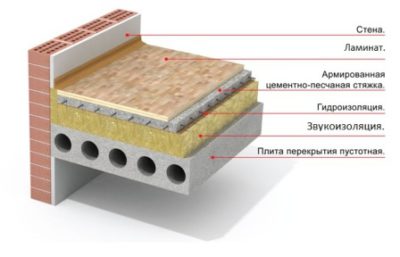

The third option, with which you can solve the problem of impact noise - arrangement of a "floating" floor. Its peculiarity is that the floor covering is not connected neither with the flooring, nor with the walls, which means that sound vibrations are not transmitted with it to the apartment. This ensures good sound insulation of the floor under the screed.

What materials can be used?

Since sound insulation can be performed in various ways, the material for soundproofing the floor can be used differently. The construction market offers a wide selection of materials of domestic and foreign production: soundproofing boards and mats based on glass or basalt fiber, varieties of mineral wool materials, foam, technical cork, rubber, wood-fiber boards, chipboard, as well as fine-grained slag, expanded clay screening ( for dry filling) and others.

The main components of the materials are divided into the following:

- polymer or plastic (liquid polymer sound insulators, reflective materials, foam);

- mineral (cement-based solutions, expanded clay, mineral wool);

- wood-shaving (sawdust, chipboard and plywood);

- silicate (glass wool).

Sound reflection and noise absorption are the main parameters when choosing soundproof materials. Sound absorbing substances are divided into types according to the degree of hardness:

- solid (created with the participation of granular mineral wool, and in their composition granules of perlite and vermiculite);

- semi-rigid (mineral wool with a cellular structure is used for their manufacture);

- soft (base - fiberglass, mineral wool and felt).

Sound-reflecting (prevent the penetration of sound into the room) include solid materials: concrete, brick, stone, drywall, etc.Sound-absorbing (they allow sound to pass, but stop its further spread) belong to materials with a cellular, fibrous and granular structure.

Floating floor device: operating procedure

For those who find the sound insulation of the apartment floor with their own hands something incredibly complicated, we suggest that you familiarize yourself with the sequence of this procedure and make sure that the technology of the floating floor device is available even to a self-taught master.

Surface preparation

The base for the floating floor must be flat, clean and dry. Therefore, the preparation phase must be taken seriously. The old coating is completely removed. Check the base for height differences, if they are significant, then it must be leveled. Self-leveling mixes or a cement-sand screed will do.

Formwork device

In order to prevent the appearance of acoustic bridges that reduce the effectiveness of sound insulation, it is necessary to isolate the flooring from walls and partitions. To do this, equip temporary formwork around the perimeter of the entire room from plywood, drywall, thin boards. Its height should be greater than the flooring of a floating floor. After the screed hardens, the formwork is removed, and the resulting gap is filled with the remnants of noise insulation materials or with mounting foam, for example.

Laying soundproofing material

Soundproofing is laid on a prepared base without gaps and cracks, evenly. To keep waste to a minimum, installation begins from the corner of the room. If necessary, the joints are glued.

Sand and cement screed

Before installing a cement-sand screed on a soundproofing substrate, it is recommended to lay an oilcloth, the edges of which are bent up and glued to the formwork with tape.

“Beacons” 10-15 mm high (pieces of drywall, etc.) are installed on the oilcloth, reinforcing mesh is installed on top of them. Next, you need to lay the guides in level, these can be metal profiles, for example. Sand-cement mixture is laid on top, it is well leveled, the surface is wiped.

Dry coupler

To avoid “wet” procedures, you can arrange a dry screed. Apply for this sheet materials: drywall, gypsum sheets, plywood, OSB. Sheets are laid in two layers, bonding together with glue. To avoid the appearance of acoustic bridges, the joints are displaced. The surface, if necessary, is puttied and covered with waterproofing mastic.

Next, lay any floor covering: laminate, tile, parquet board, linoleum or carpet, in accordance with the technology.

Video examples of the use of various materials

Than hear a hundred times, it is better, of course, to see once. We offer you a visual demonstration.

Flor Butts Plates from Rockwool

The use of soundproofing material "Shumoplast"

In the article, we examined how the easiest way to make noise insulation and what materials are best used. If you decide to execute it yourself, then our recommendations will help you successfully cope with this task.

2 comments