Wooden flooring: an overview of 6 different ways to make a wooden floor

Wood flooring is a fairly old method of arranging floors. But despite this, he does not lose his popularity to this day. Only manufacturing technology, installation methods and materials used are changing. Otherwise, the environmental friendliness and practicality of this flooring is unrivaled. The different arrangement of wooden floors allows you to use them in any room and on any basis. Consider the main types of wooden floors, their advantages and installation features.

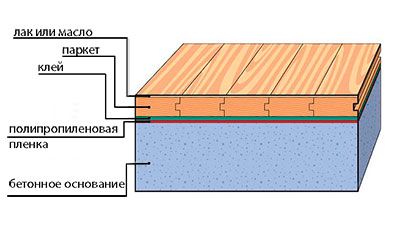

The device of the wooden floor glued to the base

The easiest way to install a wooden floor on the base is by gluing. This method is good for private houses, new buildings and other houses in which it is not necessary to raise or level the base. The device of this gender is quite simple. Glue is applied to the concrete screed. It not only impregnates the base, but also is the first layer of waterproofing.

The second layer is polypropylene or polyethylene film. Its thickness should be at least 1 cm. If the film is thinner, it is necessary to lay several layers overlapping each other. A small approach to the walls is made from the edges. The film is covered with glue on top of which the parquet is laid. After which the floor is opened with varnish or oil.

Design Advantages:

- the cheapest type of laying wooden floors;

- minimum raising of the base, due to the small design, the floor level rises to the thickness of the floor covering;

- ease of installation, this method of laying a wooden floor does not require special skill;

- it is a suitable design for the equipment of the “underfloor heating” system.

Mounting Features:

- such floors require an even and solid foundation, a deviation of 3 mm in height over an area of 2 m? is allowed;

- it is undesirable to glue the wooden flooring onto the floor covered with a leveling mixture, this will reduce the reliability of the structure if the technology is not followed or the adhesive used is incompatible with the leveling mixture.

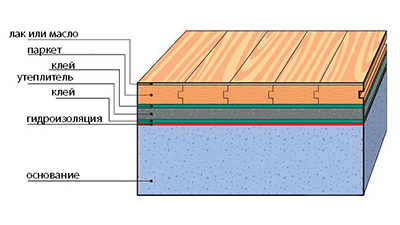

Comfort floor

To give the wooden floor sound and heat insulation, there is a gluing method with improved comfort. To make the flooring warmer and absorb noise, use an additional layer of insulation. It is placed between the floor covering and the polypropylene film coated with glue. As a heater, you can use a technical cork or isolon.

Design Advantages:

- in addition to the advantages described above - additional sound and heat insulation.

Mounting Features:

- the insulation is not able to level the substandard base, it repeats the contour of all the dents, which can lead to deformation of the floor covering;

- it is necessary to choose a heater capable of withstanding the load of a wooden coating;

- the price of flooring will increase with the use of insulation.

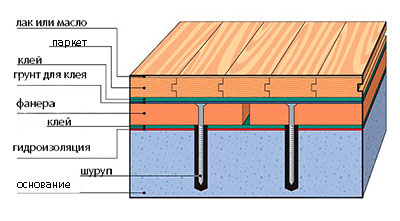

Using plywood to level the base

In older buildings, it is often necessary to level the foundation in front of the flooring. It is no secret that new buildings do not guarantee a perfectly even foundation. To eliminate such bumps use plywood or OSB panel.In the device of such floors there are the above-described layers for floors on the base and plus a layer of plywood.

It is laid on top of the glue on concrete, glue is applied on top and the floor covering is laid. For greater strength, plywood is screwed to the base with screws.

Design Advantages:

- this method is cheaper compared to using leveling mixtures;

- such a device of floors allows you to equalize the height of the flooring in different rooms;

- the ability to align the base with a deviation in height of up to 1cm.

Mounting Features:

- the thickness of plywood or OSB panels should not be less than the thickness of the wooden floor laid on top;

- flooring is done on a dry base;

- for better adhesion of plywood to glue, its surface is grinded and primed before use.

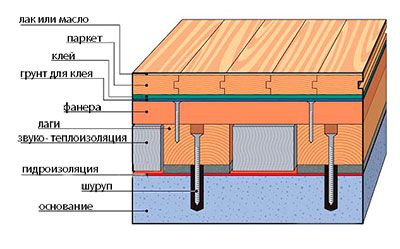

Wooden floor on logs

More complex than the rest of the device wooden floor lags It is necessary in rooms with a deviation in height of more than 1 cm. Most often, this design is used in private or old houses. In its composition, in addition to the described layers, lags laid on the base are used. For sound insulation, there should be a special substrate under them. Logs are attached with screws to the base. Plywood in this embodiment is attached with screws to the beams. Thermal insulation material is laid between the lags.

Design Advantages:

- the ability to equip additional floor insulation;

- alignment of the base having significant differences in height;

- the structure can be equipped immediately on a concrete base without the need to level it.

Mounting Features:

- the use of such a design significantly reduces the height of the room;

- the distance between adjacent lags should not be less than 60 cm;

- the thickness of the plywood or OSB panel laid on the logs should not be less than 2.2 cm.

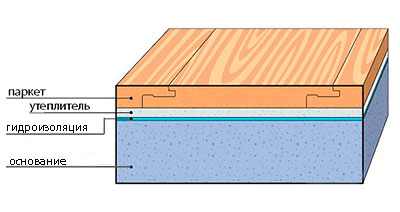

The device "floating" wooden floor

The floor design by the "floating" method is arranged from boards laid on a substrate. However, there is no strong bond with the base and walls. That is why this method is called "floating". It consists of waterproofing laid on the base. Next is the substrate, and then the flooring.

Design Advantages:

- this technology of arranging wooden floors is one of the simplest and does not require special skills;

- the method of flooring without the use of glue is much cheaper;

- thanks to a simple device, laying of such floors is carried out in a short time.

Mounting Features:

- such a floor is laid on a flat base, a deviation of 3 mm by 2 m is allowed;

- the insulation used must have a high density to drown out the noise;

- it is undesirable to put massive furniture on the "floating" floor.

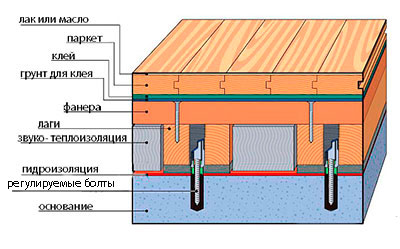

Floor with adjustable lags

In the construction of the floor on adjustable lags, the support for them are plastic rack bolts. Thanks to the rotation of the bolt, you can change the installation height of the lag. Otherwise, the floor device is similar to the previous version.

Design Advantages:

- with the help of an adjustable design, it is possible to align significant deviations in height at the base, up to 20 cm;

- the design is quite light, it can withstand any overlap.

Mounting Features:

- so that subsequently the floors do not creak, it is necessary to thoroughly clean the surface after all work and make sufficiently strong joints so that they do not loosen later;

- if the floor is raised to a considerable height, it is advisable to use insulation material, laying it between the lags.

Such a variety of wooden floor devices allows you to choose the necessary design. Which one will be chosen depends not only on the preference of the owner, but also on the specifics of the object.And the strength and durability of such an option for flooring will depend on compliance with the installation technology and proper care for it.

1 comment