All you wanted to know about floor lags and lag floor technology

Despite the relatively short operational periods of multilayer wooden structures, their light weight, environmental priorities, and economy act convincingly on owners. While foam concrete, brick, gas-silicate blocks can still argue in the field of wall construction with natural organic matter, lumber is still leading in the field of flooring. Basically, for the device of multilayer wooden structures, floor logs are used, made of durable polymer compounds or of wood.

What attracts owners to a floor with peculiar air cushions formed by laying polymer or wooden blocks? The list of benefits includes important items, such as:

- excellent thermal insulation characteristics;

- affordability of lumber;

- formation of a minimum load on the foundation, on beams or concrete floor slabs;

- the ability to raise the floor plane to any level;

- reduction in building materials costs;

- the speed of construction of the wooden floor structure, which does not make us wait for the screed to solidify;

- availability of technological space convenient for installation of communications;

- ensuring the optimal microclimate inside buildings or rooms;

- the ability to perform the laying of wooden floors on the logs yourself.

In addition, a well-made floor device for logs will exclude a rather expensive leveling process, since it fully performs its function. The presence of ventilation voids in the floor structure will extend the operational life of the lumber used to equip the lumber, which is nevertheless recommended to be treated with antiseptics, anti-wood and fire products. Thrifty owners can use bitumen instead of an antiseptic.

Content

Design and technical features

Floors with lags can be laid on an earthen base and on floors constructed of powerful wooden beams or reinforced concrete slabs. Regardless of the type of foundation, identical materials are used for the floor structure.

What can lags be made of?

Logs are called cross beams of the floor, on top of which a finishing coating is laid. It is extremely rare that metal and reinforced concrete beams are used as lags, most often wooden blocks or progressive polymer products. Wooden blocks are chosen mainly because of their cheapness, polymer because of the speed of construction and the simplicity of their installation.

Note. Instead of a beam, which for some reason could not be purchased, there may be used boards selected in accordance with the dimensions of the section of the beam, pairwise stitched together. It is permissible to oversize the section. In such cases, the installation of a lag for the floor, made of stitched boards, is made on the rib.

To this day, builders of chopped houses use instead of a timber straight, logs cut from three sides with a similar diameter.In austerity mode, logs can very well replace the beam. The only condition: they must lie before laying for about a year in a dry room.

The right choice of section

The cross section of the bars selected for the device of the floor in the logs resembles a rectangle with a height multiple of 2, a width multiple of 1.5 (aspect ratio in the context of 2 × 1.5). If the floor is arranged on wooden beams, then the size of the cross-section of the bars will be affected by the span between the elements on which they will rest.

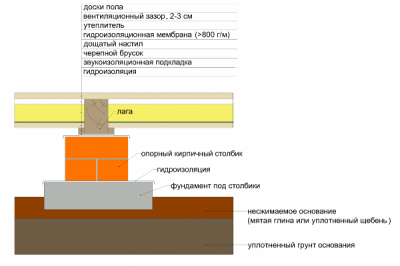

Pay attention to those who plan to equip the floor structure with a heat-insulating layer. A ventilation gap of at least 2 cm (preferably 3-4 cm) should remain between the lower plane of the finish coat and the insulation laid between the bars-logs. So, the beam needs to be bought taking into account the size of the ventilation gap. If the floor structure will rest on the ground, it will be necessary to take into account the thickness of the roll laid on the cranial block attached to the logs.

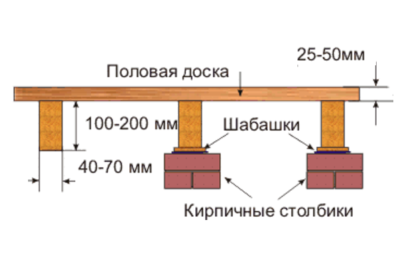

It is recommended to purchase a beam with a “margin” in section dimensions for the floor on the logs. When constructing a floor above an earthen base, so as not to use a too expensive timber of a large section, the span is reduced by installing brick columns. The intermediate distance between the supports is 1.2 m. They are made of red brick M100, silicate is applicable only if the level of the aquifer is below two meters.

Proper laying of the floor on logs with brick columns implies the equality of the distances between the rows of supports and between the elements of the beam. Before the construction of brick supports, a foundation of 40 × 40 cm is poured under each of them. The foundation can also be poured in the form of a tape under a number of brick pillars. In each row of the support column there are two bricks, the height of the support depends on the level of the elements on which the beam will be supported (beam of the lower trim, grillage made of concrete).

Lag installation step

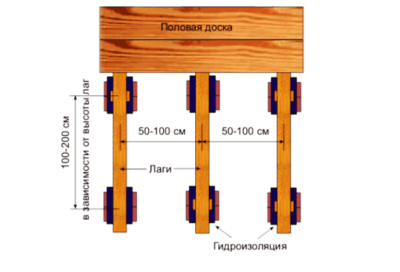

The step between the lags is an important parameter on the basis of which the calculations of material consumption are made. You can draw a plan of the rooms and accurately calculate how much timber and brick with cement are needed if the floor is not laid on the floor. This is the value between the axes of the elements located parallel to each other. The size of the step is affected by the power of the finish coating and its strength characteristics. That is, when laying a coating that can withstand a large load, the distance between the logs of the floor can be increased.

Before laying thin materials, lags will have to be installed often (0.3-0.4 m for laying boards up to 24 mm thick). For boards with a thickness of 50 mm, the distance between the axes of the log can be 1 m. Basically, a 40 mm board is used to equip the house, logs are stacked with a distance between the axes of 70 cm. Reducing the step between the elements, as well as increasing the cross section, will increase the strength of the structure, but also increase expenses. Only the owner should decide what is more important for him.

Laying the floor on the logs with your own hands should remember that the indentation of the element extreme from the wall should not exceed the step between the logs. Usually they retreat from the wall by 20-30 cm.

Geometric styling guidelines.

Orientation in space is a significant component of the correct arrangement of the floor. Those wishing to learn how to put the logs on the floor correctly, should observe the following construction rules.

- The flooring of the boards in the lounges and living rooms is carried out along the direction of the stream of natural light. Lags are located "in the cross" in the direction of the boards.

- In vestibules, hallways and other rooms with heavy traffic, boards are laid according to the direction of movement, logs, of course, in a direction perpendicular to the direction of the elements of the floor covering.

Note. If the floor structure is strengthened by installing two layers of timber, the upper layer is laid “in the cross” of the previous one.

Mounting Methods

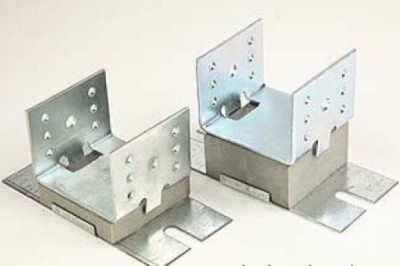

Previously, lags were attached to concrete slabs or beams simply with nails. Not the best and not long-term method was replaced by fixation using galvanized metal corners. The instruction on how to fix the logs to the floor reads:

- Fixing the corners is done with self-tapping screws.

- One of the planes of the corner is attached to the beam.

- The depth of penetration of the self-tapping screw into the timber is 3-5 cm.

- The corner is attached to the bottom rail in the same way.

- To a brick support or concrete grillage, which must be covered with a layer of waterproofing, fastening is done with dowels.

Instead of a corner, a U-shaped fixture can be used.

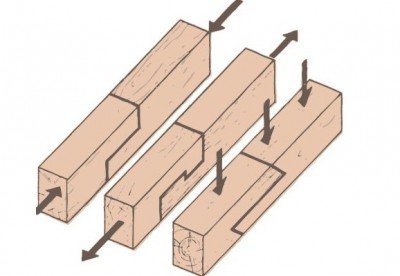

It often happens that the standard length of the beam is not enough. Elements can be docked in two ways:

- close to each other;

- by cutting, called "in the floor of the tree."

Attention. Joining places should be strengthened by sewing with nails to one, or better to two sides of the timber, pieces of lumber 1 m long.

When installing the beam in the run between the points of connection of the beam should be at least 50 cm.

Ground floor work sequence

A practical democratic floor cake on wooden logs can be arranged before the construction of load-bearing walls, for example, a frame house, or during the interior decoration. It is recommended to finish the floor after all plastering and painting operations.

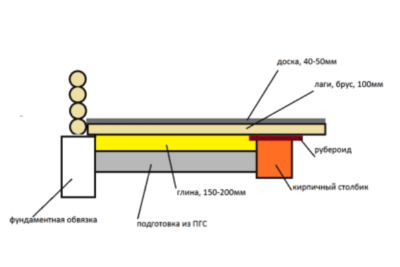

When arranging a multi-layer cake above the ground, work is performed with the following sequence:

- The vibrator or the end of a simple log compact the soil.

- Fill compacted crushed stone with a layer of 5 cm, it will fulfill the function of an incompressible base.

- Cement is poured into the formwork specially made for each support or for a number of supports.

- Brick supports are constructed (there must be a layer of waterproofing between the base for the supports and the brick).

- One more layer of waterproofing and a soundproof gasket are placed above the support.

- Install and fix the logs.

- Then they place a cranial bar and arrange a plank flooring made of cheap lumber.

- Behind the coast, another layer of waterproofing is again located.

- Insulation is placed between the lags.

- The upper plane of the entire installed beam is leveled by squeezing the excess, the presence of deviations is detected by the spirit level.

- Be sure to leave a ventilation gap between the floor boards and the insulating layer.

- At the end, the floor boards are laid indented from all walls along the perimeter by 2 cm. This gap is necessary to compensate for the movements of wood occurring under the influence of moisture and temperature. After they are looped and processed by the finishing team (the relevant articles must be read about the implementation of these works), this gap is closed with a skirting board.

With the device of the floor above the floors, the process is reduced, since the logs are attached directly to the beam or to the reinforced concrete slab.

Adjustable lag device

Convenient innovative scheme - installation of adjustable plastic logs that withstand about 5 tons of load per m2. In the lags designed for the operative installation of the floor, there are threaded devices for adjusting the floor level. Logs are rigidly attached to the rough concrete surface with dowels, to the wood with self-tapping screws. Excess lengths are simply cut off.

Video example of work

It is not too easy to build a multi-layer cake of the floor on wooden logs, but it is he who significantly reduces the budget for construction or repair. In addition to minimizing the consumption of materials, the pace of finishing production is also increasing.Thorough adherence to the technologies for arranging this floor construction scheme and following the recommendations guarantees long-term operation and aesthetic appeal.