Floors in a wooden house: which base is better + device of a wooden floor on beams

Warmth, comfort, life and complete harmony with nature - these are the words that come to mind when it comes to a wooden house. A special microclimate and, what is extremely important, natural air exchange always reigns in such a dwelling. However, one cannot but agree that the care and maintenance of a house made of natural wood require a special approach. For example, the construction of floors deserves close attention.

Content

Base design parameters

What gender will be in terms of functionality and visual perception is up to you, but in any case it should be:

- Equal.

- Warm.

- Practical.

- Aesthetic.

- Long lasting.

What needs to be done to achieve these conditions - let's figure it out together.

In fact, the device of the floor in a wooden house can be conditionally divided into three stages:

- The study of the general structural properties of the floor cake.

- Consideration of installation technology of its various types.

- Choosing and translating into reality an acceptable option.

Frankly, in terms of the most suitable for arranging floors in a house made of timber or a log house, only two materials can be considered: concrete and wood.

Note! Regardless of which type of floor is preferred, modern technology allows you to mount the system warm floor.

Concrete floor

Benefits: significantly less time is spent on all the work than installing a full floor slab of lumber. The second indisputable advantage of a concrete floor is its profitability - the cost of finishing is significantly reduced. Well, and finally, the process of pouring concrete foundation does not require special building skills, everything is quite simple: a screed is poured from the levels purchased at a specialized store at the set levels. As a result, a perfectly flat surface appears on which any floor coverings can be laid.

disadvantages: With minimal vibrations of the load-bearing walls, cracking of the concrete base is possible, and this will at least lead to heat loss. Installation of such a floor significantly increases the load on the foundation, therefore, if the correct calculations have not been done before, then problems may arise with this part of the building structure.

Wooden floor

Benefits: undoubted environmental friendliness - no harmful substances are released during operation. Unique solutions in the sense of interior design. If necessary, repairs can be carried out using improvised materials and tools.

Important! For a wooden floor to be practical and durable during installation, it is necessary to comply with all technical requirements and recommendations set forth in the relevant regulatory framework.

disadvantages: relatively high cost and complexity of installation work. In addition, it requires a lot of labor when laying, and it is very difficult to achieve perfect evenness of the coating.

Do I need a rough floor in a wooden house and why do I need additional waste for its arrangement? And what is meant by this name? We will talk about all this in detail in a special article:https://floor.expertexpro.com/en/ustroistvo-rmnt/chernovoj-pol-v-derevyannom-dome.html.

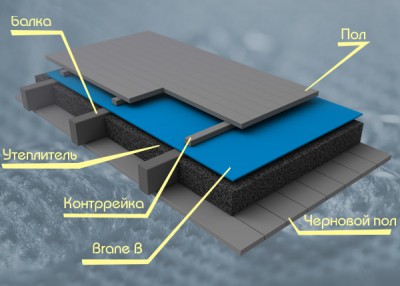

If with a concrete floor everything is more or less clear, then it is worthwhile to dwell on the wooden version in more detail, since laying a floor in a wooden house directly depends on the technical features of the cake. As a rule, we are talking about a multilayer structure consisting of such elements:

- Draft floor.

- A layer of heat and waterproofing.

- Fine floor.

- Flooring.

Attention! If it is supposed to install a “warm floor” system, then the space between the rough and finish layers is ideal. Moreover, it is quite possible to form a closed autonomous heating system, which is absolutely invisible to prying eyes and very effective.

Wooden floors can be single or double layer. In the first case, the installation can be performed without using the lag. This mainly depends on the girder distance and the thickness of the floorboard.

It happens that the wall structures of a wooden structure under the influence of various circumstances are slightly displaced, followed by the rough floor. And it is the multilayer floor structure in a wooden house that provides strength and immobility of the upper floor covering.

Attention! If the beams are brought into the walls of the house, then laying logs, which are bars 5x5 cm or 6x6 cm, is a prerequisite. The reason is the large intermediate distance between the beams.

Also, lags are extremely necessary when the flooring is carried out with the use of support columns and at the same time the step between them and the beams is 100 cm. The distance between the beams itself depends on the thickness of the board.

The sequence of laying the wooden floor on the beams

In order to maximally describe this fact, it is worth characterizing the pie of the floor. So, his device consists of such events:

- Subfloor mountings - boards or OSB boards are used.

- Laying the waterproofing layer.

- Laying insulating material.

- Laying vapor barrier.

- Laying the final floor.

Waterproofing a wooden floor is a very important point in flooring equipment. You can find out about different types of waterproofing in the material:https://floor.expertexpro.com/en/ustroistvo-rmnt/gidroizolyaciya-derevyannogo-pola.html.

Important! Between the final floor and thermal insulation, an air cushion with a minimum thickness of 1.5-2 cm must be left. In this way, natural air circulation under the floor will be ensured. To effectively ventilate the underground in the corners of the rooms or in the baseboards, holes with a diameter of 4-5 cm are made.

Selection of material for laying the final floor

When creating a finishing floor, milled boards are often used, having a groove-spike connection on the ends. The width of the material can be 9.8-14.5 cm, and the thickness is 2.8-4.4 cm. Each board on the back is equipped with a longitudinal recess of 0.2 cm, it is called "duct". It is also designed to allow the natural movement of air masses under the floor.

It should be noted that in wooden construction, when installing floors, along with milling boards, the following materials are used:

- board with a straight, segmented or trapezoidal spike;

- tongue and groove board;

- a board with a lath in the tongue.

Such building materials are characterized by planed face only and lack of air. Since the back side remains untreated, the process of flooring is more difficult, since the slightest roughness is fraught with a loose fit of the boards on the beams or logs. If the unevenness is not eliminated in time, that is, it will lead to sagging of the board.The most time-consuming is the use of unedged boards, because before laying it is first necessary to plan the front part, and tear off the bite with an ax. The laying process is reduced to nailing the boards with nails on the front side.

Very important! Whatever dock should be used, when laying it, it is necessary to observe the alternation of annual rings of wood in different directions.

Some repair features

Over time, any floor under the influence of temperature extremes and various mechanical loads sooner or later fails. Naturally, there is a need for its repair. This process can be performed quickly and easily, and can be difficult and time consuming. Everything will depend on the nature of the damage.

For example, to eliminate such a nuisance as the creak of floorboards, everyone will be able to independently. For these purposes, holes with a diameter of 12-16 mm are drilled opposite the lag, into which "milk" from cement is then poured (cement and water 1: 1). As soon as the solution hardens, a wooden cork on the glue is driven into the hole, as deep as possible. The residue is cut off, and the surface at the place of repair is cleaned and treated with a protective substance (wax or varnish).

However, if floor defects are more serious, then, most likely, it will be necessary to replace the floor in a wooden house - partial or complete. As part of this article, we will dwell on the process of replacing some boards. It is immediately worth noting that this work will be quite troublesome, if only for the reason that you need to choose the material that will be most suitable for previously installed boards.

It is very important at the stage of preparing the wooden floor to be coated with tinted or protective compounds to properly sand the surface. It doesn’t matter whether you have installed a new floor or decided to restore the old one; Read how to do this here:https://floor.expertexpro.com/en/ustroistvo-rmnt/shlifovka-derevyannogo-pola.html.

If it is necessary to replace the grooved board, then first you need to cut the screw with a hacksaw, and then, carefully separating the damaged board from the main system, replace it with a new one. To seal the resulting gaps, it is necessary to use a special putty, and when everything dries, it will be advisable to paint the floor to achieve visual uniformity of the floor covering.

In some cases, it may be necessary to perform lag replacement, for example, if it is clear that the floorboards are bending. In this case, a certain number of floor parts are removed on the problematic area, unsuitable lags change, and if necessary, additional supports are installed.

We hope that our detailed tips will help you choose the most suitable floor model for you in a wooden house, perform its installation in a high-quality manner and avoid mistakes during its operation.

1 comment