Aligning the wooden floor with plywood: all about laying plywood on a wooden base

Modern flooring technologies have also affected flooring. Residents give their preference to such ones as cork, parquet, laminate. When using these materials, not the least place is occupied by the requirements for evenness of the base. In view of this, it is often necessary to face the need to level the wooden floor. There are several ways to do this. One of them is leveling the floor with plywood. In order to correctly perform these works, you need to know how and with what help plywood is attached to a wooden floor and what preparatory work should be done.

Why exactly plywood?

Plywood has the characteristics necessary to use it during construction and repair work. She has:

- relatively light weight;

- sufficient hardness of the surface of the material;

- resistance to loads;

- high quality grinding;

- resistance to water (in moisture resistant varieties);

- lack of unpleasant odors;

- accessibility of installation technology.

For leveling wooden floors, plywood is indispensable.

In addition to an affordable price, it has the advantages that are necessary for such work. Namely:

- due to the perpendicular arrangement of adjacent layers, plywood sheets have high strength in all directions;

- the production of large sheets of plywood allows for faster installation on large areas;

- plywood sheets bend well, without breaking at the same time;

- plywood sheets are convenient for transportation and unpretentious in operation.

Preparatory phase of work

Naturally, laying plywood on a wooden floor should be done correctly and using the necessary tools. It’s good that the master has experience with this inventory. To lay plywood you will need: a screwdriver; jigsaw; level; roulette; screws with dowels.

Before you begin leveling the wooden floor with plywood, it is recommended to check the foundation for suitability for use. Replace old rotten boards and repair creaking. It will not be superfluous to check the evenness of the base. If the floor is uneven, then you need to determine the maximum surface drop. Small deviations can be smoothed out by laying a special substrate. Swings of more than one centimeter suggest laying the logs horizontally. They are set using a water level. The choice of plywood depends on the subsequently installed flooring. If it is carpet or linoleum, thin sheets can be used. For parquet or laminate, it is necessary to choose plywood thicker than 10 mm.

Note. The thickness of the plywood laid under the laminate or parquet should not be less than the thickness of the floor covering.

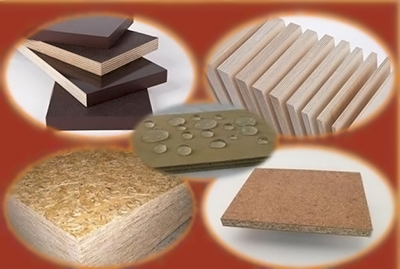

Identify the brand of plywood

Before starting work, it is necessary to determine the brand of the product. It is determined in accordance with the moisture resistance of the material. The FB and FOF brands are used for industrial construction. For individual construction work, FC and FSF plywood is intended.

In the manufacture of plywood FC use glue without the use of phenols. Therefore, it is completely harmless and can be used in bedrooms and children's rooms. It is resistant to mechanical stress and is characterized by medium water resistance.It is produced both in polished form (Ш1 - polished on one side, Ш2 - on 2 sides), and in unpolished (NS).

FSF plywood is characterized by increased water resistance, wear resistance and mechanical strength. These properties do not change even with changes in temperature and humidity. This is achieved through the use of phenol-formaldehyde adhesive resins. At the same time, these resins are quite toxic. Therefore, such plywood is not advisable to use in residential premises.

Cutting and fitting plywood

The first thing we do is “cut” the plywood according to the size of the room. In this case, it is necessary to take into account the size of the damper joints: 3-4 mm between the workpieces and a centimeter near the walls. If this is not done, temperature and moisture changes will lead to “swelling” of the finished base. Upon completion of the cutting, we check the ends of the workpieces for delamination and defects. Damaged sheets are not recommended; they must be replaced.

After that, we lay the plywood on the wooden floor in the order in which they will be fastened. It is not recommended to make a joint of four corners. Sheets of plywood are laid in the manner of brickwork, with a shift. Then you need to number all the sheets. Focusing on the joints between the sheets, mark the location of the lag and remove the blanks. Joints of plywood sheets should be in the middle of the lag.

Installing a log on a wooden floor

Logs for leveling the floor are made of plywood 3-4 cm wide. We lay them according to the marks made. We fix the logs to the floor using special glue for wooden products or self-tapping screws. During installation, gaps may appear between the floor and the logs. We lay in them pieces of plywood suitable in thickness. Before laying, grease both sides with glue.

The same must be done if the base has height differences. The horizontal location of the lag is determined using the level. The evenness of the future sex depends on the thoroughness of this process. After laying the lath, a crate is made, its size should correspond to the size of plywood. The space between the lags can be filled with a sealant.

Fixing plywood to a wooden floor

After the logs are installed, we fasten the plywood to the wooden floor according to the scheme. Before this, the workpieces must be treated with an antiseptic. We mount using self-tapping screws with plastic dowels. So that plywood does not suffer from hammer blows, we drill a hole equal to the diameter of the dowel in the places where the screw is screwed in. And then countersink a hole of a larger diameter. A hat of a self-tapping screw will hide in it.

The final processing of plywood depends on the flooring chosen. Under the carpet, the surface is covered with several layers of varnish. For a laminate, the plywood base is carefully sanded and then coated with protective varnishes. Under a laminate or parquet, a special sound-absorbing substrate is laid on the base.

Using such plywood flooring technology, almost any base can be leveled. With careful work, the result is a solid and even surface. After that, it is possible to lay at least linoleum at least parquet on it. The floor covering laid on such a base will last more than one year. In addition, the plywood layer serves as additional thermal insulation.

1 comment