Polymer self-leveling floors: a brief overview of DIY application technology

Each person who decided to make repairs in his apartment, first of all tries to get acquainted with new technologies and the most popular design solutions. If we are talking about floor coverings, polymer bulk floors deserve unconditional attention. It cannot be said that the technology of their installation is simple and affordable, but in principle, if you try hard, then do-it-yourself polymer bulk floors is a very real development.

Polymer flooring is the most unpretentious, but at the same time the most beautiful solution for the arrangement of this part of the room. The name itself indicates that polymeric materials are used in their construction. As a rule, they are included in the form of a liquid, which polymerizes during technological processing. And as a result, the floor surface is smooth and uniform. This type of flooring, made on an acrylic basis, has a high curing rate.

Important! Due to the rapid polymerization, the commissioning of floors is possible after a short period of time.

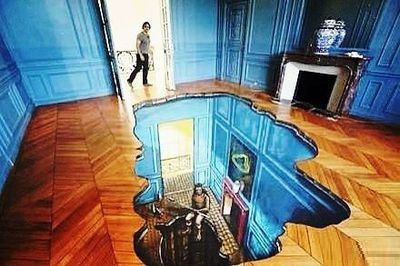

Characteristics of 3d bulk floor

The epoxy system is characterized by such advantages:

- High elasticity due to which the coating is able to withstand strong shock loads.

- Resistance to low temperatures, which allows them to be used in the construction of open trading floors, the installation of floors on the territory of commercial enterprises of various specializations, as well as when covering floors in freezers.

- Wear resistance, i.e. the ability to withstand high mechanical loads over a long period of time.

- Lack of dust emissions.

- Simplicity and accessibility of cleaning.

- Resistance to chemicals.

- Absolute inertness to various environmental influences.

- High flexural strength and comparable compression.

- Unique decorativeness and aesthetics, a special effect gives 3D varnish. Possibility of producing a textured surface and drawing a pattern.

The composition of bulk floor mixtures may vary and this directly affects the appearance and functional features of the final surface. You will learn about what material is best and what to choose for your room in the article:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/kakoj-nalivnoj-pol-luchshe.html.

Interesting! Polymer floors are characterized by different component composition, where the determining ingredients are the following types of resins: polyester, epoxy, polyurethane and methyl methocrylate.

The disadvantages of this technology:

- 3d polymer floors - expensive, because component materials are very expensive.

- Installation itself is also expensive, since the topping application is performed in “live” concrete.

- Installation on a new foundation involves a technological break - at least 28 days.

- Difficulties in need of repair - increased aesthetic requirements are imposed on polymer bulk floors. But when performing local repairs it is very difficult to get into the color scheme - it is almost impossible.

- Vapor tightness.

Very important! Polymeric decorative floors produced on a concrete base that does not have active waterproofing will be subject to delamination after a certain time, that is, delamination.This is due to the rise of groundwater vapor in the natural capillaries of concrete slabs.

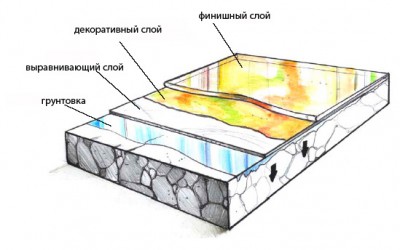

The technology of the device bulk polymer floor

Foundation preparation

In order for bulk polymer floors to serve for a long time and effectively in their production, strict adherence to all technological stages is necessary. In principle, as with the installation of floors from other materials at the initial stage, due attention is paid to the preparation of the base - and it does not matter, we are talking about concrete or wood. Although in fairness it should be noted that after all, most often such a coating is applied to a concrete screed.

The base is thoroughly cleaned of debris and dust. All cracks, chips and other defects are closed. And, besides, thorough drying is carried out - at an industrial scale, vacuum drying machines are used. In domestic conditions, the involvement of a heat gun or gas burner is sufficient. In order to improve the adhesion of the polymer to the base, the base is treated with a primer. In addition, thanks to such protection, all microcracks and pores will be closed, thus, during operation, swelling will be avoided.

Self-leveling floors are designed to reduce labor costs and the duration of the arrangement and due to this it can be filled with a home master. About the rules of installation and the wisdom of the technology of the device of such floors with your own hands, read the material:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/delaem-nalivnoj-pol-svoimi-rukami.html.

Polymer application

We emphasize once again: the main defining moment that characterizes polymer floors is technology. It is its unquestioning implementation that will allow you to create ideal polymer floors on your own. So, you need to start applying the polymer composition at a favorable temperature in the room. If it is cold, then it is necessary to heat the air to at least 100 C. It is this temperature that is recommended by most manufacturers of polymer floor materials known today.

To mix the ingredients, it is better to use a construction mixer or drill with the right nozzle. The solution must be kneaded very quickly - for everything about everything 2-3 minutes. The fact is that it catastrophically quickly freezes. The finished mixture is instantly poured onto the base.

Note! In the process of mixing the component components of the polymer coating, the release of heat generated due to a chemical reaction between them is fixed. For this reason, it is recommended to place the mixing container in a larger vessel with cold water. Thereby, the polymerization time of the solution will slightly increase.

Further, the device of polymer floors implies spontaneous distribution of the mixture over the surface under the influence of gravity. Air is expelled from the poured mixture by a needle roller. And along the walls is a temperature seam. You can look at the video in more detail on the execution technology:

According to some reports, only 30-40% of all bulk floors are ideal. Others have defects associated primarily with violations of the technology of their device. We will tell you about 7 popular defects, the causes of their occurrence and methods of elimination here:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/defekty-nalivnogo-pola.html.

In some cases, it becomes necessary to perform a thick coating. In this case, the work is carried out in stages, and each previous layer is carefully dried and cleaned of dust before applying the next.

We hope that our tips will help you to create a reliable flooring with a unique design solution without any difficulties. If there are incomprehensible moments, then you can find their permission on other pages of our site.

1 comment