How to make a bulk floor with your own hands: all the wisdom of device technology

The goal of the development of bulk floors was to reduce the labor costs and the duration of the arrangement, associated with outdated leveling and finishing schemes. An abundant range of compositions perfectly copes with the solution of both problems, making it possible in a short time to create a strong, perfectly even, monolithic surface, pleasing with tightness and the absence of seams. Technological priorities are justifiably added to the list of operational advantages, thanks to which a self-leveling filler with careful observance of the rules can be filled by a home foreman who does not have a construction specialty in the track record.

Content

Specific features of bulk floors

To a family of bulk floors, called self-leveling solutions by the people, we with some degree of error include:

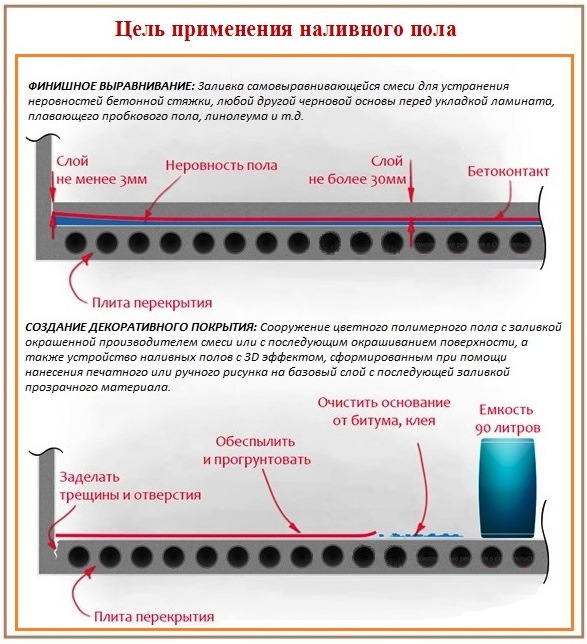

- and new plastic levelers with which a rough screed is used. The power of the layer created by them varies depending on the formula and the manufacturer’s promises from 1 cm to rarely needed due to the high cost of 30 cm;

- and finishes used for thin layer final leveling. Their thickness is calculated from a pair of mm to 2.5 cm.

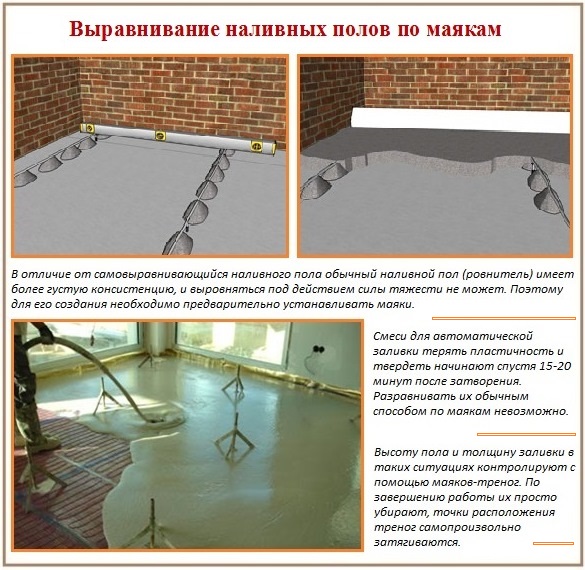

Despite the fact that they work mainly in a well-coordinated tandem, are produced by the same manufacturers, and they have a similar foundation, these are different materials, both for the purpose and for the laying methods. Leveling agents that differ from the old cement-sand mortars with optimized spreadability and ductility are applied to the floor in the usual way with leveling along beacons. They do not possess the ability to independently form a flat plane under the influence of gravity.

Class finishing mixes Not without reason is called leveling masses. In fact, they are bulk floors, colloquially called liquid linoleum. It is not forbidden to use them to eliminate major base defects, but because of the impressive cost there are few who wish to. The liquid consistency and the presence of plasticizers in the finishing versions ensures the spontaneous formation of a perfectly smooth surface without the use of levels and placement of beacons. Their advantages are less work with an incomparably higher result.

Functions of bulk levelers

Leveling agents are needed to fill the base subfloor. However, their use as a rough basis is completely optional. The base for the final polymer coating will serve as a double-coated cement-sand screed, plywood flooring or plank floor covered with insulation. Just paired materials of the same brand work better, and there are no problems with compatibility. In addition, the polymerization of the leveler occurs 4 or more times faster than the hardening of the screed made of sand and cement.

There are many types of polymer flooring today: for every taste, style and idea. We’ll tell you all about this kind of coverage with an analysis of the nuances of technology in the article:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/polimernye-poly-svoimi-rukami.html.

In terms of thermal conductivity, progressive and outdated leveling materials differ slightly.Therefore, in order to increase the heat-insulating qualities of the floor, they are laid over the same heaters. And they are also used as a heat-conducting element in systems "warm floor”, If the manufacturer indicated this possibility in the marking.

Note. The “underground” water heating system is poured in with a leveling device in layers, at least in two steps. Pipes are pre-filled with liquid at room temperature.

Secrets to Using Finishing Blends

Mixtures for thin-layer final casting are applied over almost any substrate. Only select products in accordance with the manufacturer's instructions regarding compatibility. The priority is still cement and polymer base materials. Among the functions of the finishing compositions, leveling is proudly featured, but since they are poured predominantly with a layer of up to 5 mm, it is advisable to exclude gross "relief" flaws. Even if the tubercles and depressions can be completely smoothed out with a leveling mass, there is a strong argument in favor of the preliminary elimination of defects. Bulk floors of different capacities will harden unevenly, and strength indicators will vary significantly.

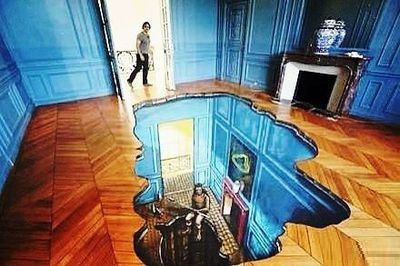

If earlier in the colorful range of finishing self-leveling compositions dull gray and cream tones prevailed, now home craftsmen figuring out how to make a bulk floor can actively fantasize about the future decor. It can turn out a plain color coating with the color laid down by the manufacturer or 3D version with a unique patterncoated on top with an epoxy transparent layer.

Why do you need information about the composition?

Regardless of the basic or final purpose of the mixture include a similar set of components, these are:

- binderssuch as good old cement, giving the floor a gray color, gypsum, attracting a pleasant beige palette, or compositions of the mentioned materials, including polymer components;

- placeholders - traditional sand or crushed limestone, the fractional size of which in the basic levelers reaches 1.2 mm, and in leveling compositions an average of 0.5 mm;

- modifying additivesintroduced into the flooring formula to improve flowability, to increase ductility, to improve an important property - adhesion.

Polymers are the binding components of foreign mixtures, due to which the characteristics are improved along with a parallel increase in prices.

Dyes that also define the color of the future floor or the base background for applying stencils, hand-painted, banner images, etc. are also introduced into the dry mix formulas. To increase the bonds between the hardening components of the bulk floor, microfibers are included in the composition of a number of bulk mixtures. Their chaotic direction firmly connects the ingredients in all possible directions, eliminating the possibility of cracking.

The dominant component that affects the choice of a mixture suitable for the arrangement is its basis. Owners who want to make the device of the bulk floor with their own hands need to deal with this issue before purchasing the material:

- dry compositions with cement as a binder are suitable for filling floors in kitchens, showers, bathrooms, separate bathrooms, i.e. in rooms requiring regular wet hygiene and in rooms with characteristic high humidity;

- mixtures with gypsum in the base are applied to the rough floor in “dry” rooms.

For the installation of underfloor heating, a leveling mass with increased elasticity will be required, capable of expanding and narrowing without the formation of a network of cracks. If you want to finish the finish at an extremely high pace, you need to pay attention to fast-hardening products. There are also universal dry materials suitable for roughing and final leveling, you can buy a mixture with the designation "especially durable" for laying coatings without first strengthening the base. Information on specific properties is available on the packaging.

You can read about the various methods of pouring polyurethane floors and useful design tips in the material on our website:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/nalivnye-poliuretanovye-poly.html.

Options for the device of bulk floors

The layout of the floor using bulk solutions depends on the planned thickness of the fill, on the degree of destruction and on the material from which the base is made:

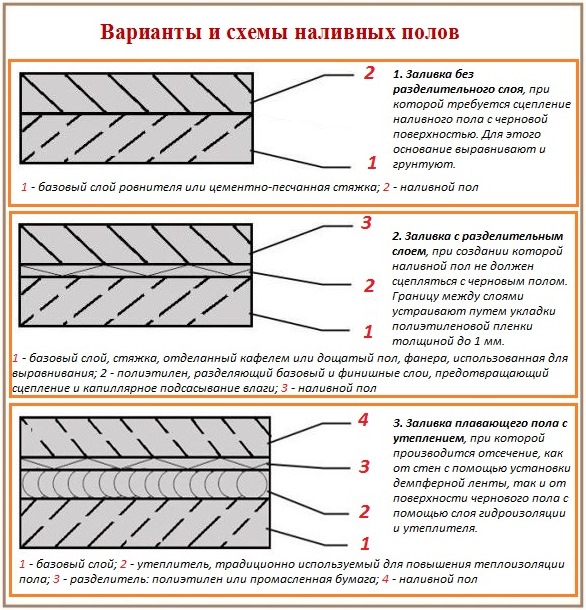

- Thin finish up to 0.5 mm, a fresh screed is poured, the surface of which complies with technical regulations. Thin-layer liquid linoleum should firmly adhere to the base. To increase adhesion, the rough base is coated with primer. Often, to improve adhesion, the underlying cement floor is pre-treated with a large emery abrasive or scraper, and then coated with a primer.

- Bulk floor, cut off from the base by a separation layer, they are arranged over a wooden base and over a screed of any type with a layer of 1.0-2.0 cm. To form a separation layer between the wooden floor and the fill, oiled paper is overlapped. The border between the screed and the bulk floor is created by treating the surface with waterproofing impregnation. The flooded layer in this case does not adhere to the surface of the rough base. Thanks to the separator, the eternal movements of the wood will not cause damage to the floor, and the cement screed will not draw moisture, creating unwanted caverns and sinks in the body of the fill. By the way, 3D floors with a volumetric effect are arranged according to this principle, only a banner with a pattern, a sticker or an original image made with acrylic paint serves as a separator.

- Floating floors arrange in the case of subsequent laying of the laminate, linoleum, parquet floor dies - i.e. coatings with the property to change in a linear direction with temperature fluctuations and with an unstable humidity level. The reason for the preference for a floating floor may also be a thickness of 2.5 cm or more, not allowing the bulk floor to harden without defects. The separation layer is created from polyethylene, rolled waterproofing or parchment, laid in strips with 8-10-centimeter overlap. It is necessary to lay a separator with 10-15 cm allowances on the walls. From the walls, the floating layer is cut off with a damper tape used to ensure the movement of the floor and for sound insulation. The separator and damper material, towering above the floor plane, is cut off before installing the baseboard and the seam is covered with it.

These are only the basic schemes of the device of bulk floors, requiring, if necessary, refinement and modernization, taking into account specific conditions. In real life, there are much more options, but the principles are general.

Rules for pouring self-leveling solutions

You can fill the leveled leveling mass on the floor in rooms with equipped window and doorways. Drafts should not be, about ventilation with the help of natural and forced ventilation during the hardening of the floor you need to forget. A solution without extraneous coercion needs to lose moisture during the ripening process. The temperature in this period should be stable without indicators below 5º C and without take-offs above 20º C. Priority humidity 60%.

We assume that the alignment and climb to the planned height has already been completed, i.e. the base layer has already been created or we accept the existing tile, cement or plank floor as it. Next, we find out how to make bulk floors with our own hands, pronounce the magic word "so."

Preparing the surface for the upcoming treatment:

- We repair a concrete or cement draft floor, embroider to a centimeter wide crack and fill it with a repair compound, cement-sand or a mixture intended for future pouring. We cut perceptible relief bulges with a perforator and remove unreliable segments.The remaining cavities and small cavities after removal are filled with a solution, equalized flush with the plane of the rough base.

- We check the floor tile for fixation strength. With unreliable elements, we act as with concrete elevations. We fill the seams, indentations with the solution.

- Wooden floors, we repair according to the rules for their restoration. We change the dubious elements, renew the fasteners, foam the cracks, fill it with carpentry glue with sawdust or sealant.

We remove oil paint, grease stains, detergent residues with solvents, then carefully remove dust from the floor with dirt with a damp cloth and a vacuum cleaner.

If you are going to remodel the bulk floor or partially repair an existing one in your room, then it will be useful for you to read the following article:https://floor.expertexpro.com/en/pol-pokritiya/nalivnoi/kak-ubrat-nalivnoj-pol.html.

Depending on the chosen pattern of pouring the leveling mixture, primer or cover the insulation layer. We place a damper tape around the perimeter if a floating floor will be constructed.

Step by Step Pouring Process

The solution must be shut, strictly adhering to the instructions of the material manufacturer. Violations of proportions and deviations from coaching are not permissible, entailing a deterioration in technological qualities and operational characteristics.

Important. The polymerization of the mixture for manual pouring occurs in 35-40 minutes. after cooking. Accurate information about the life of the solution must be indicated on the package.

Due to the shortness of the period of suitability of the solution for pouring, attempts to arrange a bulk floor without an assistant must be stopped in the bud. It is better to enlist two pairs of friendly hands and initially distribute responsibilities. One prepares the mass, the second pours, the third distributes with a spatula or ironing on a long handle.

It remains only to list the actions, following the sequence:

- We install a limiter in the doorway - a rail, a section of drywall or profile. We will do likewise if it is not possible to fill in one step in a too large room or if you plan to install combined floors.

- The mass prepared according to all the rules is poured into strips of a width of not more than 50 cm. The first strip runs along the wall opposite the entrance.

- Avoiding any breaks, fill the second strip, at the same time evenly distribute the solution with a spatula or iron. And so we act until the end of the work.

- We process the flooded layer with an aeration roller, so that the bulk floor will part with air bubbles. During processing, we move along the surface in kraskostah - in shoes with supporting spikes on the sole.

- We cover the fill with polyethylene and wait for the time required by the instructions required for the maturation of the self-leveling mass.

If it is necessary to impart anti-slip properties to the surfaces, the flooded floor is sprinkled with washed sand or not too zealous, expelling air from the mixture with an aeration roller. "Craters" remaining from bursting bubbles will prevent slipping.

It’s easy to understand the technology of applying a self-leveling floor, to perform, showing skill, too. Just find out all the important points you need in advance, take into account the specifics of technology and correctly plan actions. Knowing the nuances of the fill will not hurt those who decided to entrust it to the workers.

6 comments