Parquet looping: do-it-yourself technology review

There is a saying: “Once a repair is started it is impossible to finish, it can only be suspended.” But it’s true, keeping up with fashion is almost impossible. Almost daily, new construction and decoration materials appear on the market. Not having time to enjoy the repair just completed, we are surprised to find new wallpaper or flooring that would fit much better into the interior than what we chose just a month ago. Fortunately, there are materials for which fashion never passes. If we talk about flooring, then this is certainly a wooden parquet. Even after many years of use, the usual hingeing of parquet will help to restore its former beauty to it, and it is quite possible to do this procedure with your own hands, though it is troublesome. After restoration, your parquet will become a real decoration of the room.

What tools and materials need to be prepared?

For high-quality parquet hitching, special equipment is needed. Buying it for personal use is impractical because of the high cost (unless of course you plan to engage in scraper professionally), but renting such a tool is quite affordable.

So you will need:

- Drum-type cycling (parquet sanding) machine - the rental price is about 600 rubles / day.

- Surface grinding machine for scraping parquet - rental price from 1500 rubles per day.

- “Boots” - equipment for looping corners. It should be noted that such equipment appeared relatively recently, and before that the processing of corners was carried out by manual cycles or “grinder” with a special nozzle. So you can easily get by with "old-fashioned" methods and save a little.

- Sandpaper in rolls. You will need several types of abrasive: for rough processing P40, and for grinding P80 or P120 (depending on the type of wood).

- As auxiliary equipment, you need to prepare scissors for cutting sandpaper, keys for clamps on the drum of a looping machine (they usually come with the machine, but anything can be rented with equipment), a powerful vacuum cleaner.

Remember that the weight of a looping or grinding machine can be about 70 kg, so one fragile woman should not follow her. But the dimensions of the unit allow you to transport it in the trunk of a car. As a rule, renting a car for one day is enough.

After making simple calculations, you will understand how much the scraping of parquet with your own hands costs. The figure that the construction company will ask for work will be several times larger.

Preparatory phase - foundation preparation

Before you begin the process of hitching, you must carefully prepare the room:

- We take out furniture;

- Vacuum and wash the floor;

- Examine the base for loose or falling dice. If such are found, they must be re-glued;

- Carefully remove the skirting boards. In many old houses, skirting boards are nailed to the base, as they say, tightly. In this case, when dismantling them, you risk damaging the parquet. If the skirting board cannot be removed carefully, it is better to leave it in place;

- We check for sticking nails or self-tapping screws. If we find, we drive in or delete.

Remember to also check the wiring status. The fact is, during operation, the parquet scraping machine consumes up to 2.5 kW of energy, and the starting power is even more.Make sure that wires and circuit breakers are rated for this load.

Step-by-step floor processing technology

If you plan to use the rented equipment, then it is better to go after him to open a store, and then immediately begin hitching. Be sure to stock up on protective equipment: a respirator and glasses - from dust, ear plugs - from noise.

Stage # 1 - Scrapping

First you need to make a rough scraping of the floor. At the same time, scraping of the old parquet will allow you to remove the old varnish from the surface, and when processing a new parquet, get rid of bumps and dirt. At this stage, the top layer of wood up to 5 mm thick is removed.

- Set a rough emery tape on the drum. In most cases this is P40, sometimes P60.

- We pass the first row along the diagonal of the room;

- We shift the machine to half the width of the drum and go through the next row;

- Thus, we grind the entire floor, changing the abrasive as necessary.

The drum pressure on the floor is usually regulated by a special screw. If you see that the engine cannot gain the required speed, reduce the pressure. If the machine removes too small a layer, and the engine is operating normally, increase it.

Stage # 2 - Grinding

The next processing step may be the last one if your parquet is not too damaged. But hitching dead parquet will require at least three passes.

For the second stage of processing, you will need P80 sandpaper - for heavily damaged parquet or P120 - for the final processing. Now passages must be done along the dies, that is, along the wood fibers. A fine abrasive will help to remove scratches and “stains” from rough sandpaper and make the wood completely smooth.

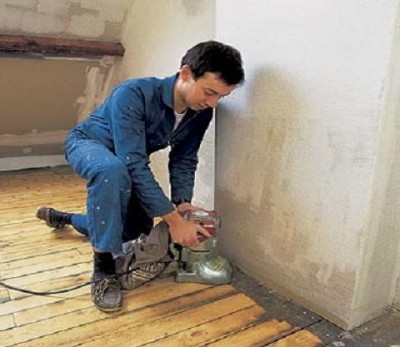

Stage # 3 - processing corners and hard-to-reach spots

After grinding is completed, you will see that along the walls and in the corners there were uncultivated areas - the car simply didn’t get there. This is where the “boot” comes in handy - the curb looper. If it is not there, pick up the scrubbing and remove the old varnish, and then “finish” the surface with the “grinder” and the grinding nozzle. Manual scrapping of parquet is a very hard and unpleasant job. So if there is an opportunity, it is better to find a “boot”.

That, in fact, is all. Now it remains only to return the rented equipment and proceed with the application of a decorative and protective coating - stain, varnish or mastic.

2 comments