Water heated floor: a detailed analysis of installation systems and examples of DIY installation

One of the modern elements of the heating system of a country house is a water heated floor, the installation of which with the advent of new materials is not difficult. Although collecting information about this issue will not be superfluous in order to avoid some errors and misunderstandings during the work. In apartment buildings, it is not recommended to install water heated floors, since their connection to a centralized heating network is associated with obtaining permits. In addition, during a seasonal shutdown period lasting four months of the year, the floor will remain cold. Although installing a small electric boiler can save the situation. However, it is worth listening to the opinion of experts recommending the use of other floor heating systems in the apartments of multi-storey buildings. It should be noted that in new buildings, warm water floor systems can be provided for by the project.

Content

Advantages and disadvantages of this heating system

Anyone striving to reduce the cost of maintaining their housing. By arranging a do-it-yourself water-heated floor, the owner of the house manages to save not only on installation, but also on the subsequent operation of this system. The benefits also include:

- uniform floor heating throughout the room;

- lack of visible heating appliances and their connections, which improves the attractiveness of the interior;

- heating large areas of the house at low cost;

- one-time financial investments spent during installation will provide savings on the payment of electricity in the future.

The disadvantages of the warm water floor system include:

- the presence of structural difficulties during installation;

- mandatory use of a water pump;

- difficulty in controlling the floor temperature;

- decrease in pressure in the riser;

- loss of temperature in the heating system of the following apartments;

- the presence, albeit small, of the probability of leakage, as well as the difficulty of finding it.

It is important to note that the likelihood of leakage is high if you use metal pipes that can leak due to corrosion. Pipes made of polybutylene, metal-plastic, cross-linked polyethylene (PEX) are not subject to corrosive processes. Their service life reaches fifty years.

Types of underfloor heating systems

There are two of them in total:

- Concrete technology implies the location of the heating elements of the system under a monolithic screed. This approach is associated with a large amount of "wet" work requiring time and labor costs. The finish flooring is only laid after the concrete screed has completely dried. Time depends on its thickness, with a maximum drying period of 28 days. That is how much concrete is required to gain brand strength. Despite the difficulties, this method is popular.

- Flooring technology, which is made from finished materials, therefore, the installation process is accelerated due to the lack of dirty work with concrete mortar and loss of time waiting for it to completely dry. However, more funds have to be spent on the purchase of several layers of materials. Depending on their choice, this technology is divided into three subspecies: polystyrene system; modular type of wood system; rack type wooden system.

Preparatory phase of work

When choosing any installation system, it is necessary to perform the calculation of the system for a specific room as accurately as possible. In this case, the optimal power indicator is determined taking into account the type and area of the room, the planned temperature, possible heat loss and the type of finish flooring.

It is necessary to choose a system of warm water floor of greater power, if:

- the room is located on the first or last floor;

- a large amount of glazing (conservatory, bay window, balcony);

- building envelopes are not sufficiently heat-insulated (thin walls, balcony, etc.);

- Thick marble or granite slabs, as well as materials having high heat capacity parameters, are chosen as the flooring.

At the preparatory stage, the foundation is prepared, freeing it from the old flooring. The surface must be leveled, it is allowed to exceed the surface level of the base base over the entire area of the room no more than 5 mm. In case of deviation from this indicator, the surface is leveled with an additional screed. Ignoring this requirement may cause further “airing” of the laid pipes.

Method # 1 - concrete paving system

When choosing this technology, the device of a warm floor is carried out in several stages:

1. A thermal insulation layer is laid on the cleaned base of the floor, which prevents heat from escaping in the opposite direction from the desired direction. When choosing a thermal insulation coating pay attention to the thickness of the material, which should not be less than 30 millimeters. The density of the material used for thermal insulation, which is at least 35 kg / m³, is also important. Most often, foam or polystyrene is chosen for this purpose. Manufacturers suggest using ready-made mats that have special clips. They facilitate installation, but also affect the wallet, as their cost is high. The thickness of the insulating layer must be increased along with an increase in the heat load.

2. Further along the perimeter of the room, a damper tape is attached to the wall, which is able to compensate for the thermal expansion of the screed made of concrete. A thick plastic film is laid on top of the insulating layer.

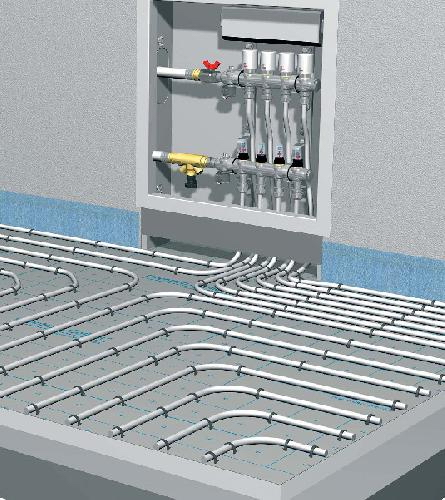

3. Then the reinforcing mesh is laid, to which the pipe is attached with plastic clamps. Corrugated pipes protect expansion joints. Some craftsmen also lay reinforcing mesh on top of laid pipes to give greater structural strength.

4. The water floor heating scheme can be made in the form of a spirally located pipe or in the form of a snake. At the same time, about five meters of the pipe takes up one square meter of floor surface, provided that the installation step is 20 cm. The location of the loops is easily modeled in special computer programs. When installing a warm floor in large rooms, the pipe is laid with several separate loops.

5. At the next stage, hydraulic tests are mandatory. This is especially true for those who install the system on their own. After all, experience is not enough, so it is better to play it safe and check the pipes for leaks, as well as for strength. Until the screed is poured, it is possible to eliminate the discovered defects made during pipe laying, or to replace them if any damage is detected. Hydraulic tests must be carried out for twenty-four hours (minimum) under a pressure of 3-4 bar.

6. After conducting a system operability check, they begin to fill the mounted floor surface. concrete screed, the thickness of which should be 3-15 cm above the laid pipes. The flatness of the mortar is ensured by the exposed beacons, according to which, using the rule, smooth the screed. The completed concrete screed is left to dry for 28 days, and water floor heating is not included. After completion of the period allotted for drying, the system is switched on, gradually increasing its temperature, and the maximum value should fall on the third day. 7. At the last stage, it remains only to cover the floor with the selected finishing coating, which can also be ceramic tiles, parquet, and laminate.

Important! When buying parquet or laminate flooring, you must choose the model, recommended by the manufacturer for underfloor heating.

Method # 2 - polystyrene laying system

One of the main advantages of this technology is the absence of the need for concrete screed. This greatly facilitates the very design of the warm floor, and the work on its installation. It is possible to keep the height of the room to the maximum due to the smaller thickness of this underfloor heating system, consisting of polystyrene plates, which in this technology act as heat-insulating material. Therefore, this technology is used if there is a load limit on the floors, as well as at low ceilings.

On top of the entire structure, a gypsum-fiber sheet (GVL) is placed in one layer if parquet is laid. In the case of laminate and ceramic tiles, as well as with other types of flooring, experts recommend laying two layers of GVL.

Progress of work:

- Prepare the base of the base floor, cleaning it from construction debris and dirt. Use a level to check for evenness.

- Then, on the flat floor base, lay the polystyrene plates in exact accordance with the drawings.

- Next, install the aluminum plates and pipes, focusing on the design requirements. Aluminum plates should cover about 80% of the floor area of the room. Fulfillment of this requirement will ensure floor heating over the entire surface.

- Next lay gypsum-fibrous sheets.

- Install the finish coating.

The polystyrene system for mounting a warm water floor can be performed on any basis (concrete or wood). For wooden houses that do not have concrete floors, there are other ways to install a warm floor. The owner of a wooden house can use the rack-type system or the modular type system.

Method # 3 - a modular type of wood system

By exercising installation of a water floor on a wooden floorperform the following operations:

- Stack thermal insulation.

- The next layer is made of prefabricated modules representing chipboards, in which grooves for aluminum plates and pipe channels are pre-cut in accordance with the drawings.

- Next, they carry out the installation of aluminum plates, as well as pipe loops by snapping them into the channels intended for this.

- Perform gypsum-fiber flooring and topcoat.

Method # 4 - rack type wooden system

The rack system is most often used when installing a warm water floor on the second floor of a wooden structure, because this technology uses a thinner layer of thermal insulation.

- Between the floor beams, called lags, heat-insulating material is laid using mineral wool or polystyrene for this.

- When laying boards whose thickness should not be less than 28 mm, grooves with a width of about 20 mm are left.

- Next, aluminum plates are inserted into the grooves left, and pipes are already inserted into them.

- Then it remains to carry out the installation of the draft coating from GVL and the finishing of the floor.

Rules for installing a collector group

In all of the above methods of installing a warm water floor, you must install collector cabinet, which is bought ready-made in the construction market. After the collector cabinet is successfully installed, a feed and return pipe is inserted into it. The first comes from the boiler and, accordingly, is filled with hot water. The second pipe, designed to perform the exact opposite function, is responsible for collecting water that has passed through the heating system and has already given off part of the thermal energy to the coating. The cooled water is sent again to the boiler for subsequent heating. The process starts anew in a circle. Water circulation is provided by a pump built into the system.

At the same time, shut-off valves are installed on each pipe (both supply and return), which allow you to disconnect the system from the general heating network for repairs, go in order to save money. A plastic pipe and a metal shut-off valve are connected using a compression fitting. Next, a manifold is connected to the valve, installing an air vent on one side and a drain cock on the other. You can put just a stub, but it is less functional. After collecting the manifold cabinet, all other work described above in each system is performed.

A few words in conclusion

Of course, within the framework of one article it is difficult to reveal all the nuances of installing a warm water floor. However, you probably got some idea about how to make a water floor heating with your own hands. At the same time, one of the readers understood the complexity of the process and decided not to go into details, but to hire professionals. Another category of skilled people did not see any particular problems and decided to definitely do the independent installation of a warm water floor in their house or bathhouse.

In any case, the comfort that this technology provides is difficult to describe in words. This is a lifestyle in which everything is thought out to the smallest detail. Today, any of you can begin to take advantage of the endless possibilities of modern technologies that have turned the idea of building new structures and repairing previously constructed facilities when you were not even aware of such opportunities.

Perhaps, having made warm water floors in your home, you will want to do these services as part of your own business. This is a very profitable business, as this market is in constant growth and the peak of consumer demand has not yet arrived. However, an increasing number of Russians want to live according to new standards of comfort, which include underfloor heating systems.

5 comments