Mixing unit for underfloor heating: what is a collector, how does it work and how is it arranged?

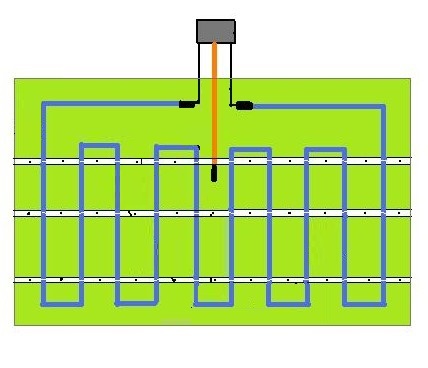

In any residential area, the issue of floor insulation remains relevant. The most common solution to this problem is water insulation, the key element in which is a mixing unit for a warm floor. But first of all, before installing the collector, it is necessary to design a pipe heating system through which warm water will circulate, and to heat not only the floor, but the whole room. Of course, designing is “loud”, since in addition to the length and width of the room, in fact, you don’t need to know anything else.

After the length and width are determined, it is necessary to choose the material from which the system will be made. Today, the best choice would be plastic pipes with an aluminum streak, they conduct heat very well and have virtually no wear time. The selected consumable must be cut to fit the room.

The number of bends of such a “snake” depends on the total length of the purchased pipes and on the required heating efficiency. Of course, the more bends, the higher the floor temperature, and the more evenly it will warm up. But at minimum distances there are also standards.

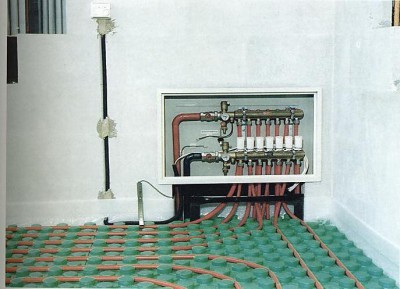

In modern construction, the underfloor heating system has the following structure: the bottom layer is made insulating, a system of heat pipes welded together is laid on it, which are covered with a bearing layer of concrete screed. The top layer is covered with a finishing layer of ceramic or stone tiles, as well as of laminated parquet, these types of floor coverings are most suitable for underfloor heating.

The total thickness of the "heat cake" ranges from 70-150 mm. This size is determined by the requirements for the diameter of the pipe, the thickness of the insulation and the thickness of the screed.

Purpose of the mixing unit and its principle of operation

After the system of plastic pipes is soldered and ready for use, the next step is the selection of the mixing unit.

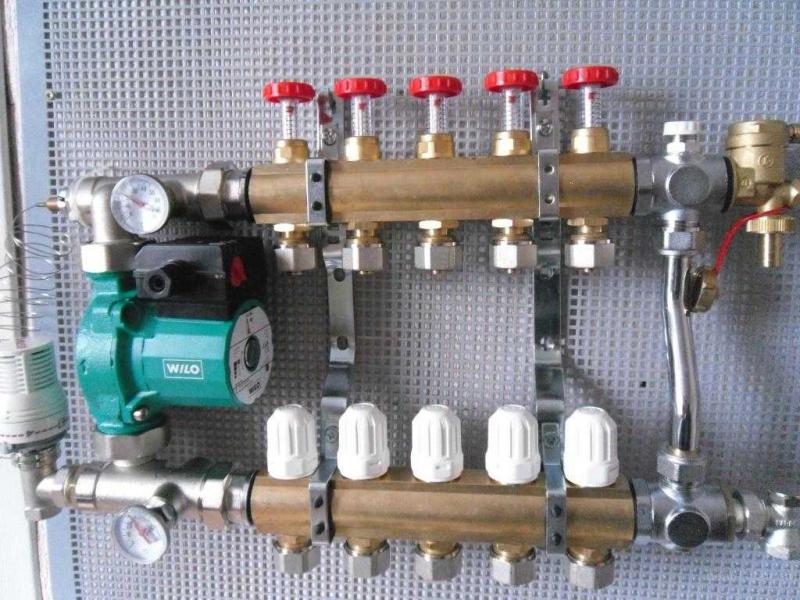

As the video said, collector for underfloor heating - this is equipment aimed at circulating and regulating the heat carrier through the floor heating system. It has two main components:

- a circulation pump circulating thermal water in the floor heating circuit;

- a control valve that feeds the circuit with hot water exactly as much as the coolant temperature is set.

There are two types of collectors: with three and two way valves.

The heat-insulated floor can be mounted directly in a concrete coupler. Read how to do this in an article on our website:https://floor.expertexpro.com/en/tepliy-pol/teplyj-pol-pod-styazhku.html.

3-way valve manifold

The first design is based on the use of three-way mixing (manifold) valves. The objective of such a valve is to mix inside itself the hot water coming from the boiler with the colder water flowing through the "return" of the warm floor. Such valves are often equipped with servo actuators, allowing to control both weather-dependent controllers and thermostatic devices.

This collector is considered the most universal, but has some characteristic disadvantages:

- Firstly, there is a possibility that, at the signal from the thermostat, the valve will fully open and let hot water with a temperature of 90 ° C enter into the system.Such a sharp jump in temperature can lead to rupture heating pipesdue to increased pressure in them.

- Secondly, three-way mixing valves have a large throughput, which is not very good for warm floors, since the minimum valve adjustment bias will seriously affect the floor temperature.

But, despite these shortcomings, this type of collector is indispensable in large-scale heating systems and in systems with weather-dependent regulation.

Details about the device of a water heated floor can be found in the material:https://floor.expertexpro.com/en/tepliy-pol/vodyanoj-teplyj-pol-svoimi-rukami.html.

2-way valve manifold

The second type of manifold uses two-way feed valves. Most experts give their preference to such a mixing unit and consider it the most correct. A feature in the work is that the mixing of the coolant with cold water from the "return" occurs constantly and the warm floors never overheat. The two-way mixing valve has a low flow rate, which ensures stable and smooth temperature control. They are the most common, but have limitations in use, it is not advisable to install them in rooms with an area of more than 200 m².

Also an integral part of the manifold are thermostatic valves and flow meters. The latter must be present, due to the fact that the length of the pipes in the system is different and if you do not install a flow meter, then the water will flow in pipes with less hydraulic resistance, that is, in short ones. The flow regulator ensures uniform circulation of the coolant throughout the system. Thermostatic regulators are designed to change the temperature separately in each circuit of the system. Using thermostatic heads, the warm floor responds to changes in external conditions and maintains the set temperature.

Here’s how to do your own repair of a water or electric underfloor heating system here:https://floor.expertexpro.com/en/tepliy-pol/remont-vodyanogo-i-elektricheskogo-teplogo-pola.html.

Advantages of the collector circuit of the device

A warm floor with a collector heating system has a lot of undeniable advantages, which made it the most used in the modern heating industry:

- Hygiene Warm floors lend themselves well to wet cleaning and disinfection, and due to their constant heating, they dry quickly, which prevents the appearance of harmful mold and fungi, since the environment of existence of harmful microorganisms is destroyed.

- Safety. Often children and even adults forget about the high temperature of the heating equipment and as a result get severe burns. When using a warm floor, burns, scratches and other injuries are simply excluded.

- Comfort. The warm floor creates invisible coziness and increased comfort; it radiates reliability and tranquility.

- Profitability. Energy saving in comparison with heating radiators in small houses reaches 30%, and in rooms with large dimensions up to 50%.

- Durability. The only thing that is subject to wear in the floor heating system is the pipe, the minimum service life of which is 50 years.

We hope that now you have an idea of such a plumbing miracle as a collector. Let everything work out in an independent device of such a system. And if you have any questions, ask in the comments.

3 comments