Heat-insulated floor under a coupler: the step-by-step device of the correct floor "pie"

Warm floors are increasingly attacking traditional heating systems. Moreover, it can be argued that they themselves are becoming a "classic of the genre." Manufacturers are trying to keep up with the ever-growing demand for elements included in the floor cake with the device of such heating. Moreover, it is now even difficult for the consumer to navigate the market offer of designs for such heating systems. But, be that as it may, no matter what heaters and heat carriers are preferred, as a result, a warm floor will be mounted under the screed.

It should be noted right away that a screed in this article refers to a layer of concrete. Its device can be performed in two ways:

- Using cement-sand mixture of the M-150 brand or similar, to which PVA glue is added at the rate of 1 kg: 1 bag.

- With the use of ready-made mixtures specially developed for the “warm floor” system, which today are many in construction stores.

Correct pie and screed thickness selection

Typically, the system is mounted on an old base, on top of which a heat insulator (foam bottle or cork with foil) is laid. This layer is an essential component in the installation of underfloor heating, regardless of whether they are water or electric.

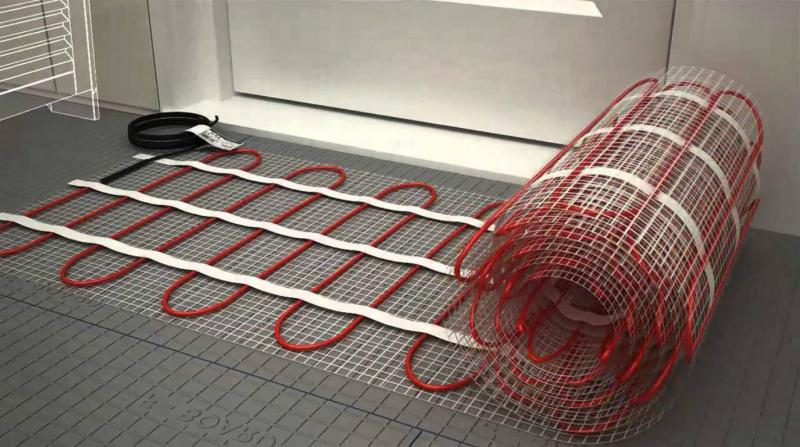

The next step is to install water pipelinecable, finished heating mats, etc. And at the finish is a concrete screed. The result is a kind of “pie” in which concrete is laid on a relatively soft material.

To increase the strength of the screed, as well as to facilitate the alignment of the floor, a plasticizer is used. You can read more about this supplement in the article:https://floor.expertexpro.com/en/tepliy-pol/plastifikator-dlya-teplogo-pola.html.

Naturally, we are not talking about excessive strength with this design. For this reason, it is recommended to make a hole on each square meter of the area of the heat insulator. In addition, around the perimeter of the area where the warm floor is laid, you need to leave 10-15 cm of free space. Thus, the upper screed will rest on the bottom. This is especially true in small areas.

Note! The heat insulator in the underfloor heating system performs another function - soundproof.

Regardless of the functional features of the “warm floor” system, a concrete screed of 3-5 cm thickness is considered normal. This will ensure a sufficiently quick screed heating immediately after the system is turned on. And there will still not be uneven heating of the floor surface, that is, the alternation of warm and cold stripes.

The cement floor is cold and needs to be insulated. About how to do this, what materials and technologies are used, you will learn from our material:https://floor.expertexpro.com/en/tepliy-pol/uteplenie-betonnogo-pola.html.

Important! If circumstances force the screed to be thinner than 3 cm, then it is advisable to add a universal plasticizer to the solution.

For 100 kg of dry mix, add 1 liter of additive. Alternatively, you can use a self-leveling mixture. This will also contribute to greater elasticity of the screed.

Phased work

So, the screed device under the warm floor consists of several stages:

- insulation is laid on the rough screed, which is better to immobilize with adhesive tape, glue, dowels;

- then a metal mesh is laid, which, in addition to reinforcing, is also useful for marking in the process of laying a pipeline, cable and film system.

- the mesh is also attached to the base;

- along the perimeter of the area on which the heating elements will be laid, a damper tape is stretched, the main purpose of which is to level the coefficient of linear tension. In addition, the tape works as additional sound insulation and thermal insulation;

- installation of the components of the warm floors around the entire perimeter of the site is carried out, connected to the coolant supply system;

- final screed of the warm floor is made, on which, after complete drying, it will be possible to lay the finish floor covering.

Confused in technology and warm systems? We will help you understand all the issues in our comparative review of options and methods for installing heating:https://floor.expertexpro.com/en/tepliy-pol/kak-sdelat-teplyj-pol.html.

Important! Test inclusion of a warm floor is possible only after the concrete screed has completely hardened, after about 45 days. If, in the work, any problems are observed, then the coupler will have to be broken and, after eliminating the malfunction, refill.

Video instructions with an example of execution

Be that as it may, the screed device is not difficult to perform. The main condition: the amount of water, cement and sand must be introduced according to the technology. In addition, it is impossible to force events, to neglect the stages and terms of the work - and everything will work out.

2 comments