Pipes for underfloor heating: which are better, quantity calculation and installation options

When choosing a heating system for a private house or a new apartment, many think about abandoning traditional batteries in favor of a warm floor. In addition to the fact that such a system allows you to get rid of registers and pipes, often disfiguring an excellent interior, it is also more comfortable. Electric heat-insulated floors were especially popular for a long time, but often their use is associated with additional costs for paying for electricity. And the wiring in our homes is often far from ideal and does not withstand the additional load. An excellent alternative to electric, can be a water system. To connect it, just install pipes in the floor and connect them to the boiler you already have. But which pipes are suitable for a warm floor? That's what we’ll talk about today.

Content

What pipes can be used?

It must be said right away that in multi-story buildings, the use of this technology is limited. If you completely re-equip the heating system in this way, then your neighbors from above or below (it depends on the direction of the coolant supply) will start to freeze, which will inevitably lead to conflicts and litigation with utilities. And you are unlikely to get permission for such changes. All this allows you to talk about installation. underfloor heating system only in private homes.

The main element of such a heating system are pipes, the quality of work of a water heated floor directly depends on the correct choice of which. Let's look at all the types of pipes available today.

Option # 1 - copper pipes

The best material for underfloor pipes is, of course, copper.

It is these pipes that are used in most European countries. Copper has excellent thermal conductivity and durability. The only, but very significant drawback of such pipes is their price.

Option # 2 - pipes made of metal

The most common version of pipes for underfloor heating.

Thanks to the inner layer of aluminum, they have good thermal conductivity, and the inner and outer layers of the polymer make such pipes resistant to damage and “overgrowing”. And the price of this material is quite affordable.

Option # 3 - polypropylene pipes

Polypropylene pipes are used as rarely as copper pipes, but for other reasons. Their main disadvantage is a rather large bending radius - at least 8 diameters. And this means that with a pipe thickness of 20 mm, the distance from one section of it to another will be at least 320 mm, which is often not enough.

Option # 4 - PEX pipes

PEX pipes or pipes made of cross-linked polyethylene have a sufficiently large thermal conductivity and wear resistance. Moreover, their cost is low. The main disadvantage of such pipes is that they have to be rigidly fixed during installation. Otherwise, the pipe will bend.

Installing a warm floor system is not as complicated as choosing the right floor covering for it. What can and cannot be placed on water pipes or an infrared film, and what are the consequences of all this, will be described in the article:https://floor.expertexpro.com/en/tepliy-pol/pokrytie-dlya-teplogo-pola.html.

Calculation of the required number of pipes for the system

When the choice of pipes suitable for you is made, it is time to calculate the required amount of material. To do this, draw a laying diagram. It is most convenient to do this on graph paper, transferring the dimensions of the room to scale on it. In addition, you must measure and apply to the scheme all the large pieces of furniture that you do not plan to rearrange. Laying underfloor pipes under them is not recommended. In the remaining space, you need to draw a pipe laying diagram. The most common are the methods of laying the "snake" and "spiral".

Laying pipes in the first way is much easier to design and perform, but it has one significant operational drawback. The fact is that in this case the coolant enters the underfloor heating system from one side of the room and is gradually sent to the other along the snake. On the way, the water in the system cools down, which means that the part of the floor closest to the inset will heat up significantly more than the outermost.

Laying the pipes in a spiral allows you to distribute the temperature much more evenly due to the fact that the pipe from the inset goes to the center of the room, and from there back to the collector.

It should be noted that the length of the pipes in one circuit should not exceed 60 meters. Otherwise, the coolant will cool too much, and the system will be ineffective. It is advisable to divide the premises of a large area into several sectors, in each of which to lay a separate contour.

You should retreat from the walls by 15-20 cm and draw a plan for laying pipes. The distance between adjacent sections of the pipe should not exceed 35 cm, otherwise the floor heating will be uneven. On average, a pipe with a diameter of 16 mm is able to warm up 10-15 cm of the surface on both sides of itself.

After the drawing is ready, it is necessary to calculate the length of the pipe. To do this, just measure it on the diagram and multiply by scale.

What to do if there was not enough pipe? It happens. Here is how one master came out of this situation:

A detailed analysis of installation systems with examples of DIY installation of a water heated floor can be found here:https://floor.expertexpro.com/en/tepliy-pol/vodyanoj-teplyj-pol-svoimi-rukami.html.

What else will you need for installation?

So, the material of the pipes is selected and their number is calculated. Now you need to decide what other materials and devices you need for the installation of the system:

- Thermal insulation. Under the pipes, it is necessary to lay a layer of thermal insulation. It can be polystyrene or EPS.

- Waterproofing. Multifoil or plastic film - waterproofing and additional thermal insulation.

- Damper tape. It is laid along the walls and between sections of the room with different heating circuits. It is designed to compensate for the expansion of the concrete screed due to heating.

- Reinforcing mesh. It is called to strengthen the screed, and will serve as the basis to which the pipes will be attached.

- Anchor brackets are special clamps for fastening pipes.

- Manifold for underfloor heating. This is a device that performs the function of distributing the coolant along the contours. If there are several circuits of different lengths in the system, the collector must be equipped with flow controllers. This is due to the fact that when an equal amount of coolant is supplied, the long circuit will heat up much weaker than the short one. In some cases, water may not go into a longer circuit at all because of the high hydraulic resistance.

- Mixing unit. This device is necessary if not all rooms in the house are heated using a warm floor. In the cold season, the temperature of the coolant supplied to the radiators is quite high, and the warm floor is a low-temperature system. It is in the mixing unit that the supplied coolant is diluted already cooled to the required temperature.

Installation and connection of the pipeline

The order of work is as follows:

- It is necessary to start with laying heat-insulating material and damping tape.

- Then a layer of foil or polyethylene. All joints of this layer must be glued with tape.

- On top of the waterproofing, we lay the reinforcing mesh, to which the pipes will be attached.

- Install the collector.

- We proceed directly to the laying of pipes. We connect the edge of the pipe to the collector and begin to lay it according to the plan. We fasten the pipe to the reinforcing grill. If metal-plastic pipes are used, clamps must be installed at a distance of 1 m from each other. If you prefer a more resilient material, you will have to fasten more often.

Important! In the place where the pipe crosses the damper joint, a special corrugated tire must be put on it, which will help prevent damage to the pipeline.

- When the entire circuit is laid, connect its second edge to the collector.

- Now you need to conduct a test run of the system. To do this, apply pressure to it that exceeds the working pressure by approximately 1.5 times.

- If everything is in order, it's time to do a cement screed. For this, a cement-sand mortar in a ratio of 1: 3 with the addition of a plasticizer is used. You just need to fill it with a floor, a layer of up to 30 mm. In construction stores you can find a "bulk floor" designed specifically for floor heating systems. It is much more convenient to work with it, but the price of such a mixture will significantly exceed the cost of a conventional cement mortar.

- It remains only to wait for the screed to dry and the floor is ready.

Details of the hydraulic test process:

Pipes do not need to be mounted in a concrete screed and, thus, weight and raise the floor level. Read about the design options for a “dry” warm floor in the material:https://floor.expertexpro.com/en/tepliy-pol/suxoj-teplyj-pol.html.

Alternative Water Floor Device Methods

There are much less labor-intensive methods. installation of a water heated floor, but their cost is much higher. Calculation of pipes for a warm floor of such a design is performed in the same way as for a concrete screed.

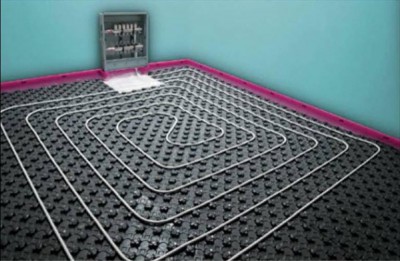

Polystyrene flooring system

This system is perfect in cases where you can not increase the load on the supporting structure of the building. The polystyrene system is also indispensable in rooms with low ceilings. It consists of polystyrene plates with ready-made grooves for laying pipes, the pipes themselves and aluminum plates, providing an even distribution of heat.

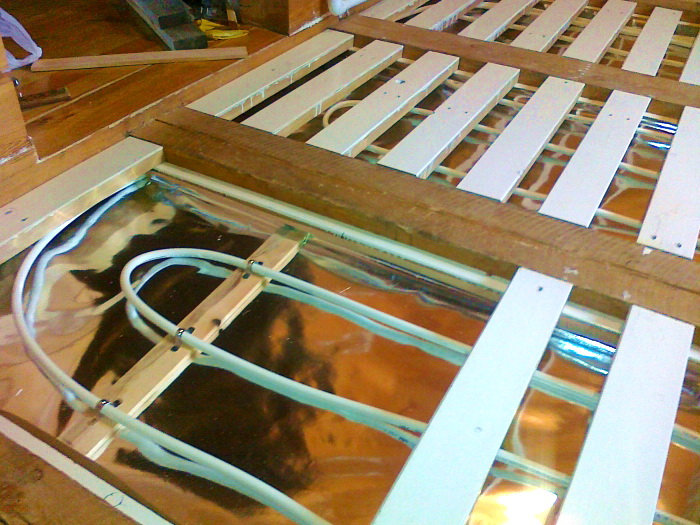

Wood Modular System

Another way of laying pipes that does not involve a “wet” process is a wooden modular system. It is made of chipboard with ready-made grooves for laying pipes. Such a system is ideal for wooden houses. It is enough to lay thermal insulation between the lag and fix the wooden modules as ordinary sheet flooring. The only condition is the distance between the logs is not more than 60 cm, and if you plan to finish the floor from ceramic tiles - 30 cm.

In custody

As you can see, the independent choice of a pipe for a warm floor and the further installation of such a system do not require special skills. The only point at which you may need the help of a specialist is calculating the power of the main heating system. You can do the rest yourself.

2 comments