What is a comb for underfloor heating: device and principle of operation

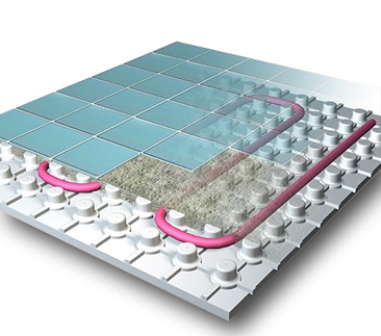

The heating system "warm floors" is incredibly popular and provides effective heating of air in the rooms below, due to the presence of heating elements under the floor. The comb for underfloor heating is a single unit that controls one separate or several closed heating circuits.

Content

What is a comb for a warm floor: the role of the node and the principle of operation

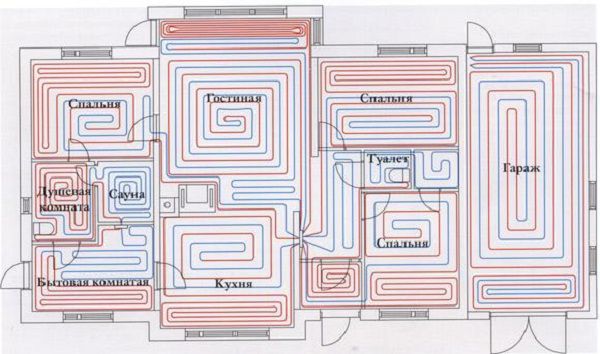

As a rule, the modern scheme of “underfloor heating” is quite complex, represented by several circuits with different pipe lengths and the amount of heat carrier, so the role of such a unit as a comb should not be underestimated.

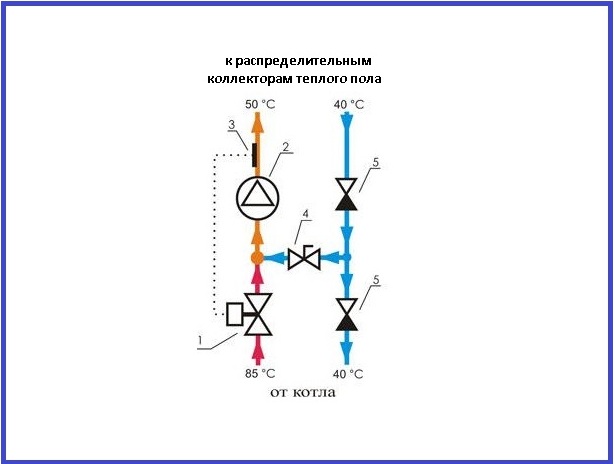

With two way valve

The main difference between the standard “comb” scheme, equipped with a two-way valve, is represented by the continuous supply of water from the “return” without the use of special shut-off type valves. In this case, the mixing unit for the “warm floors” system periodically mixes boiling water under conditions of cooling of the heat carrier below the specified parameters. This type of circuit has proven itself in practice, but only in the absence of excessive contours.

The diagram shows:

- 1 - two-way supply valve;

- 2 - circulation pumping equipment;

- 3 - temperature sensor;

- 4 - balancing type valve device;

- 5 - check valve.

The valve device of the feeding type is characterized by the presence of a built-in liquid sensor-thermostat, cutting off or adding a certain amount of hot thermal carrier if necessary. Stable temperature indicators along the perimeter make the operational life of the structure as high as possible. The advantages of this option are represented by smoothing of sharp jumps in conditions of low throughput of the valve device.

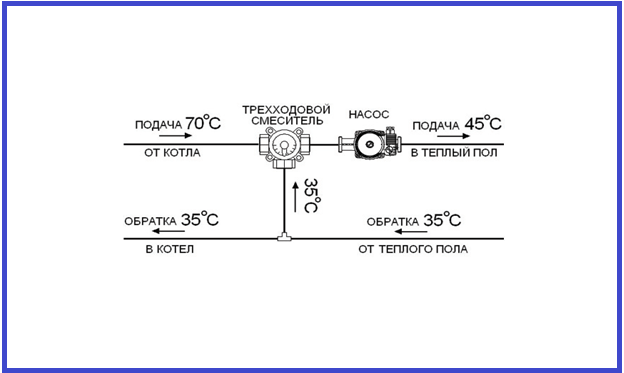

With three way valve

The category of universal equipment includes modern and highly efficient mixing units mounted in the “warm floor” system with a three-way valve device. This design involves mixing boiling water with a "return" directly inside the housing, as well as the presence of the combined function of a supply valve device with bypass balancing. An adjustable position damper is integrated in the valve.

This type of control valve is equipped in the form of special weather-dependent controllers, thermostats and servos, therefore it is the best option for installation in multiple circuits for heating very large areas.

The main disadvantage of the design with a three-way valve is the possibility of inlet of a hot heat carrier and the risk of excessive pressure inside the system, which negatively affects the pipes and significantly reduces their operational period. At the same time, the complexity of the most accurate regulation of temperature indicators is due to the presence of increased throughput, so even a slight rotation of the damper can cause a noticeable temperature change within the “warm floor” system by 3-5 ° C.

To control the underfloor heating systems, special thermostats are used. We will tell about what it is and how to choose a thermostat for your needs in the article:https://floor.expertexpro.com/en/tepliy-pol/termoregulyator-dlya-teplogo-pola.html.

How to choose a device

If you independently choose a comb for a warm floor, you need to correctly determine the functional purpose of this unit, calculate the number of loops or inputs connected to the device, and pay attention to the material of manufacture and the availability of automation, which makes the operation convenient and most efficient.

Material of feed and return manifolds

Currently available collectors can be made using traditional stainless steel, brass and high-strength plastic.

The stainless steel is almost ideal, but quite expensive option. Brass knots are cheaper, but less reliable, characterized by increased fragility.

The number of circuits on the collectors, the permissible level of pressure and water flow

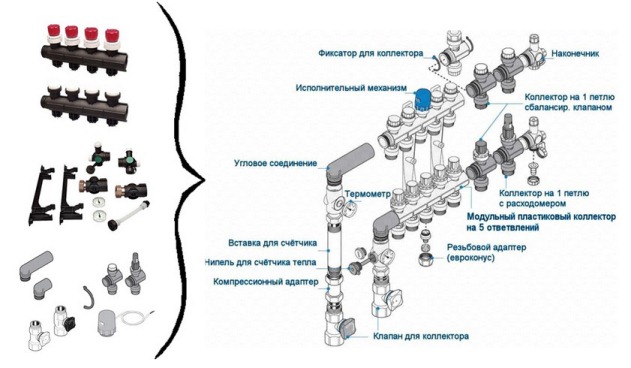

Heating collectors separating the flows of the thermal carrier are most often represented by two distribution combs. The first is the receipt of the coolant, and the second is its return. The end part is equipped with a connection to the supply or return line, and directly along the body there are fittings for hinges (circuits) of the installed underfloor heating system.

When choosing a device, it must be remembered that the standard pressure is usually about one and a half or two atmospheres, but when using air during the crimping process, such indicators should be in the range of 4–5 atm.

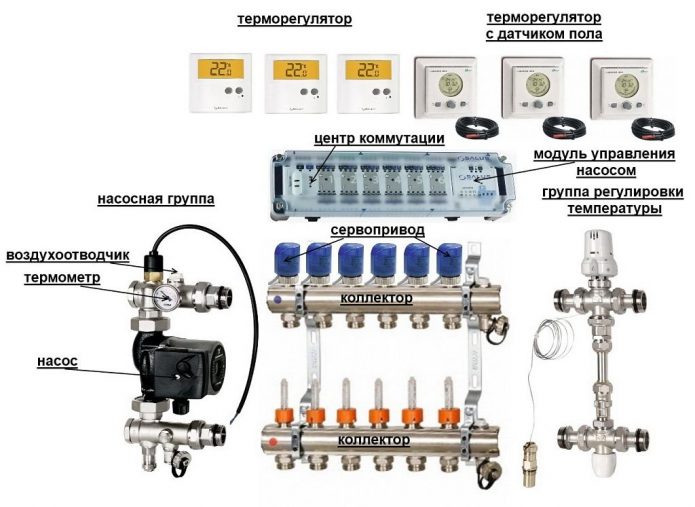

Product Automation Degree

The modern market of sanitary products is ready to present to domestic and foreign consumers technically advanced designs of combs connected to thermostats and a programmable controller, which allows you to adjust the temperature and flow of heat carrier on the circuits according to changing needs.

The rather high cost of an automated unit in practice, as a rule, pays off very quickly, due to the economical consumption of thermal carrier during operation.

Manufacturing firm

The highest quality products are produced by European manufacturers, but their cost is very high, so the price of a modern and high-quality collector, as a rule, starts from $ 1000–1200.The acquisition of affordable Chinese devices is often a risky undertaking, since such combs are usually not very durable. Nevertheless, there are a number of brands that have established themselves well and are in demand by consumers.

Table: advantages and characteristics of various brands of collectors

| Name | Characteristics | Main advantages |

| Millennium | The Chinese-made collector group for efficient and safe use in the "warm floor" system. | The comb is characterized by the perfect balance between affordable price and functionality. |

| TIM | A collector group with flowmeters made in China for the arrangement of a water heated floor and for use in a collector-beam heating distribution. | The comb is manufactured on European equipment, has a high quality, very reliable during the entire service life. It is injection molded using high quality brass. |

| Oventrop multidis | German distributor for underfloor heating system with forced circulation. | The comb is made of stainless steel and is designed for underfloor heating with integrated rotameters and control inserts. |

| Stout | Complete Italian collector made of stainless steel, equipped with flow meters that are carefully monitored. | High reliability is due to high-quality materials, the optimal configuration of the unit in the embodiment for the installation of underfloor heating. |

| Valtec | Italian nickel-plated brass collector for distribution of heat carrier flows in the underfloor heating system. | At the outputs of the comb there is a control valve to control the flow of the coolant with average indicators of the total resource at the level of eight thousand cycles. |

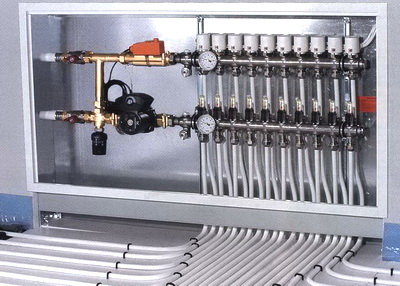

Equally important is the purchase of a special cabinet, or the so-called mounting box, into which the collector of the “warm floor” system is installed.

Assembly and installation instructions

Self-assembly of the distribution comb is quite possible, since all prefabricated products are always completely complete and are accompanied by intuitive instructions.

The standard configuration of the collector for the arrangement of the "warm floor" system is presented:

- metal cabinet;

- a thermometer;

- drain valve with plug;

- automatic air vent for each branch;

- fittings;

- thermostatic valves;

- flow meters.

Temperature control is performed by thermostatic fans, the adjustment of which can be manual or fully automatic. The second option is more convenient and practical, which affects the total cost of equipment.

Necessary tools

For self-assembly of a factory product, it is necessary to prepare a standard set of tools, as well as a traditional tow or FUM tape, to obtain the most reliable connection of all elements. In addition, special grease can be used to increase the quality of twisting on threaded joints.

Factory comb assembly

To assemble a factory-made collector, you must complete the following steps:

- After the box is unpacked, it is necessary to check the configuration and make sure the integrity of all elements.

- Then all the parts are laid out on a flat and horizontal surface in the assembly sequence.

- Assemble all the individual comb elements for the “underfloor heating” system in accordance with the instructions supplied with the unit.

- At the final stage of the assembly, small nodes should be connected to the supply and outlet collectors.

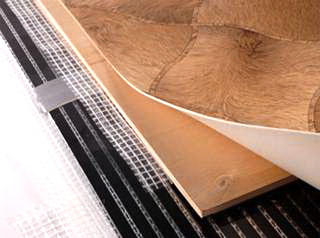

Thermal insulation is one of the important components of underfloor heating systems, which allows rational use of energy. You can read about various heaters and their installation options here:https://floor.expertexpro.com/en/tepliy-pol/penopolistirol-dlya-teplogo-pola.html.

Fixture mounting

Installation of the unit includes the following steps:

- For self-assembly of the comb in the “warm floor” system, it is necessary to unpack the mounting brackets and make sure that they are complete.

- Fix the collector part of the comb on the brackets with large and small brackets.

- In accordance with the markings made on the wall, drill holes and install the collectors, valves, thermometers, drain valves and air vents.

- At the final stage, the installation of a valve device of a two- or three-way type is carried out, installation of pumping equipment and other units included in the complete set of combs for the heating system “warm floor”.

Setting the comb for underfloor heating

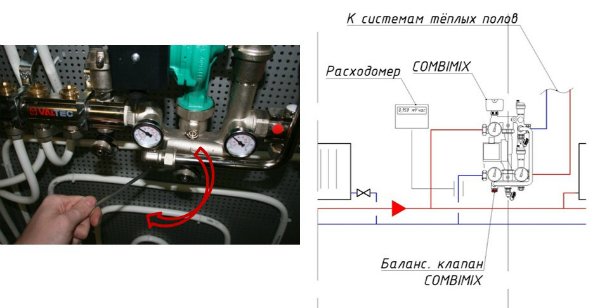

Factory products undergo bench pressure testing, as evidenced by supporting documents containing complete information about all hydraulic tests performed under special conditions. The use of such compact devices with a guarantee of tightness of welded and threaded joints is the best option in any home heating systems. Such components are characterized by an ergonomic arrangement of controls, and installation inside special mounting cabinets does not prevent access to control valves.

The heat carrier from the supply pipe and the “return” is mixed inside each outlet or directly in front of the collector, but it is advisable to entrust the calculation of the optimal circuit to specialists.

Regulation of the temperature regime of the floor surface involves the implementation of several sequential actions:

- Set the bypass valve to max, setting it to 0.6 bar. The operation of this node during the configuration process causes an erroneous result.

- Calculate the balancing valve, using for this purpose the temperature indicators at the return, flow line and the outlet of the heating device, under the conditions of a standard coefficient of 0.9 and according to the throughput formula: K = 0.9 × [(tk - to/ tp - to) – 1]).

- Set up pumping equipment by calculating the boiling water flow rate and pressure loss indicators on the circuits. It is allowed to set the minimum feed rate with the gradual addition of speed.

- Balance the branches by fully opening the control nodes and smoothly closing them to the desired position.

At the final stage of setting the comb for the “warm floor” system, the flow rate of the mixing unit is matched with other heating devices.

It should be noted that the installation of the flow meter will greatly facilitate obtaining accuracy when setting up all nodes. It is recommended to set the processing parameters of the bypass valve device approximately ten percent lower than the set maximum pressure values of the pumping equipment.

You will learn more about self-assembly of a water heated floor and the analysis of various installation systems in the material:https://floor.expertexpro.com/en/tepliy-pol/vodyanoj-teplyj-pol-svoimi-rukami.html.

How to make a device yourself

The independent manufacture of a distribution node is not too troublesome and not at all costly, so this option is increasingly chosen by home craftsmen who want to save money on the purchase of such an expensive device.

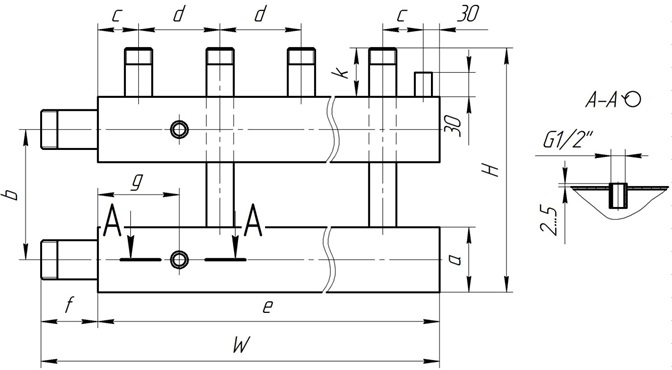

Drawing up a drawing

Before proceeding with the assembly of the comb with your own hands, it is necessary to draw up a competent drawing or diagram of such a device taking into account the number of circuits, load and other basic parameters.

Selection of the necessary material

To make a comb yourself, you will need to purchase some of the simplest parts presented:

- ½ inch brass tee - four pieces;

- ball valve with a threaded connection ½ inch - five pieces;

- silicone sealant;

- ½ inch standard plug.

Acquired tees must necessarily have a configuration in which an internal thread is present on one side of the product, and an external thread is located on the opposite side.

Manufacture

The sequence of self-production of a distribution comb for the heating system "floor heating":

- Assemble tees in a single line. To connect each subsequent tee to the previous one, external and internal threads are used, which allows you to get a straight pipe with the presence of side layers. Reliable sealing of all connections involves processing the places of threaded connections with silicone sealants applied to the external thread. All excess sealant must be removed with a rag.

- A standard faucet is installed on the inlet of the resulting straight pipe using silicone sealant and threaded connections.

- On the opposite side of the base, a plug is installed on a makeshift comb.

- All side branches are provided with screwed and sealed taps.

The self-made distribution comb obtained in this way is perfectly suitable for arranging a four-circuit “warm floor” system.

An equally popular option is an independent soldering of combs based on ordinary polypropylene pipes and additional fittings. The number of tees is selected individually, and pieces of PPR pipes should have a diameter similar to them. In this embodiment, the cut pipes serve as connecting nipples for joining the tees.

Video: homemade collector

Heating a room using a modern and highly efficient “warm floor” system is one of the most practical options in terms of saving energy resources and even distribution of heat energy. When arranging this type of heating over a large area, a special comb with manual or automatic control is necessarily used.

The use of automation in the comb control system is an ideal option that allows you to get the maximum level of economic benefit with the consumption of thermal energy. Nevertheless, such a device belongs to the category of non-public and inertial, therefore, heating and cooling of the floor heating system will take some time.