Plasticizer for underfloor heating: how to increase the strength of the screed?

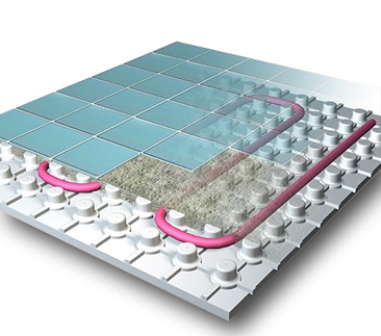

Plasticizer for underfloor heating is a highly effective reinforcing additive for filling the floor, which increases the mobility and spreadability of the floor building mixture, which acquires a dense and homogeneous structure. Due to this, the process of leveling the floor is facilitated, and the surface as a result becomes smooth. The main action of the plasticizer is to increase the solubility of cement clinker and the interaction with cement particles. During the last chemical reaction, the particles of cement are repelled, which as a result reduces the number of air pores, reduces the amount of water and finally plasticizes the mixture.

Why use a plasticizer at all?

A plasticizer is used as the basis for multifunctional compositions and dry building mixtures having a wide range of applications. In the manufacture of mortars and concrete, including cellular with high performance, also for the production of concrete products, etc.

Plasticizer Properties:

- Acts as an inhibitor, acting as a moderator of corrosion processes caused by high chloride content.

- It makes it possible to obtain waterproof and high-density concrete.

- In small doses increases strength characteristics, and nothing more.

- It is used as an antifrosty admixture (up to -25 ° C).

- When potassium nitrate is added to the concrete mixture in an amount of 5% of the total mass, the plasticizer neutralizes it and no salt formation is observed.

- When plasticizer is added to the solution in small doses, a long-term increase in strength occurs, without reducing the permeability and porosity of concrete. The setting time of Portland cement with a low soluble alkali content is also significantly reduced.

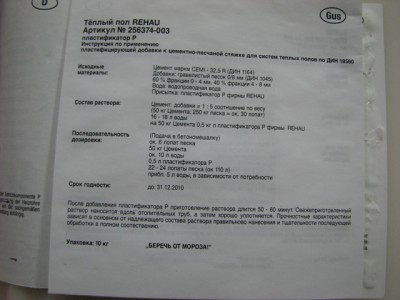

Important! A plasticizer for screed floor heating is a very complex chemical substance in its composition, and therefore it should be added to the solution in exactly the quantities indicated in the instructions for its use.

The effect of plasticizer on concrete:

- reduced setting time at the end of work, as well as when leveling floor slabs or when cultivating finished elements;

- when using subsequent batches of the solution creates a low pressure;

- increases the rate of solidification, but at the same time slows down the setting time for solutions with a low ratio of cement / water;

- during long-term transportation, liquid cement, which contains a plasticizer, can be activated with potassium nitrate, which is added to the drum of the concrete mixer;

- when concreting in the cold season, accelerated hardening prevents rapid hardening, which is preceded by significant heat generation due to hydration;

- when plasticizer is added, the result is self-compacting with high strength hydraulic concrete.

This substance not only increases the compressive strength of the product, but also the speed of its set, which allows the forming of concrete products in 12 hours, without defects and chips. Therefore, it is even possible to use lower quality grades of cement.Plasticizer almost 100% reacts chemically with cement without causing side effects.

Application procedure

Stage 1

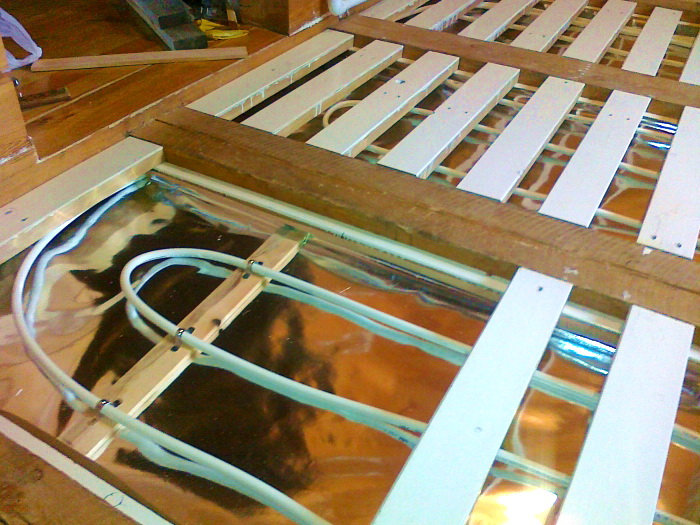

The introduction of the plasticizer into the concrete mix occurs simultaneously with other components: cement, water, aggregate, plasticizer. Then it is necessary to mix all the ingredients in a concrete mixer for one and a half hours, as a result a homogeneous cement suspension will be obtained.

Stage 2

The resulting mixture can be used to fill floors for various purposes: industrial floors, warm, public, etc. The most important thing is to evenly distribute the solution on the surface of the base.

Stage 3

The most important thing is to give the ready-made, albeit liquid floor, solidify well before use. After 7 days it will already be possible to walk on it, and after 14 - to install furniture. Complete drying and hardening of the floor is observed on the 20th day after pouring it.

With the invention of the plasticizer, most sex masters lost their headaches, now the process of laying concrete screeds has become much faster and easier. Previously, after filling the floor, it was necessary to process it with special rakes with long thin needles to remove the remaining air bubbles. Now this and other operations the concrete mixture performs itself, and this is due to the use of plasticizer.

5 comments