How to level the floor under the laminate: all possible options and their description

A perfectly aligned subfloor plane is the main condition for long-term impeccable service and the aesthetic appeal of a laminate laid on top of it. Those wishing to learn how to level the floor to the laminate can receive several equally correct, technically sound answers. It all depends on the type of base and the preferred floor arrangement. The choice of optimal technology, in turn, is focused on the size of the budget, the limits of time and labor costs.

Leveling is an obligatory preliminary stage of a full-fledged laminate laying process. If there are even minor defects on the base surface, the locks will be loosened due to the unevenly distributed load, an annoying creak will disturb, and the panel may crack over time. In order to prevent the consequences, a screed is made of a concrete or wooden base, on which the laminate is most often laid.

Content

Methods for leveling a concrete base

A concrete subfloor is often a dull confirmation of a cement screed or slab poorly made by builders, the flat surface of which is the ceiling of the room below the floor. Fundamentally, the choice of technology for leveling the cement base is focused on the condition of the base surface, which determines the amount of labor and financial costs.

If the alignment was done professionally, but managed to last a couple of decades, the destruction of the upper cement layer of the intensely loaded floor plane still occurred.

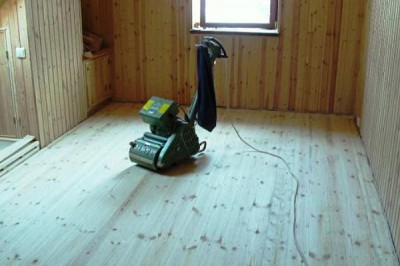

Grinding as the simplest leveling method

Minor surface level differences can be eliminated by grinding. For processing a large room, you can order the services of workers of the repair organization, performing this type of alignment using specific grinders. You can just rent equipment in the same organization. Not too damaged screed in a small children's room or in the home office is enough to bring to the required performance by processing with sandpaper.

To increase the strength of the surface, as well as in order to level it, grinding of the concrete floor is performed. As a result, the surface acquires the necessary roughness and is easily amenable to further processing. Read about how to do it yourself, choose the right equipment and all the technological steps, in the article:https://floor.expertexpro.com/en/ustroistvo-rmnt/shlifovka-betonnogo-pola.html.

Ground surface before laying laminate coated with a primer, forming strong crystalline compounds in the upper layer of the base. However, grinding work is often completed by pouring a self-leveling mixture.

Self-leveling mixture filling

Not too cheap, but quite an operational method is used to level the cement floor with elevation differences up to 0.5 cm.

- If you do not intend to multi-stage pouring a self-leveling screed, it is not necessary to mark the level and set up beacons. But to indicate the height of the screed to be performed, it is recommended to determine the highest floor point with a laser device or level gauge and make marks on the walls to which the mixture will need to be poured.

- Before pouring, the base surface is primed and a layer of waterproofing is applied to it.

- The self-leveling mixture prepared in strict accordance with the manufacturer's instructions is poured into a small strip and leveled with a spatula.

Note. It is better to cook the mixture in small portions, because after 15 minutes after cooking it loses its plasticity and begins to harden. Batch preparation and sequential processing of sites eliminates the likelihood of inappropriate consumption of material.

After applying the screed on the entire surface of the base floor, a technological break should be made, giving her time for complete hardening. It is 3 or more days. The polymerization of the mixture should take place without drafts, temperature fluctuations, it is impossible to turn on heating devices and devices of forced ventilation.

Traditional sand and cement screed

Cement-sand mixture for leveling is used in the case of significant differences. To do this, use factory dry formulations or a home-made mixture of the first part of cement, 3 equal parts of sand and water, the amount of which allows you to get a consistency similar to thick sour cream.

- On the walls, level marks are set, determined by a laser device or a simple level gauge.

- Guide rails are installed on a clean, dry floor.

- The screed is laid between the guides, then the solution is leveled with a rule or a transverse special rail.

- After a couple of hours, the surface is additionally wiped with a wooden trowel.

- A day later, the lighthouse rails are dismantled, the holes remaining after them are closed with a similar screed with the solution flush with the leveled surface.

The cement-sand leveling layer will gain maximum strength only after 28 days after completion of work. During this period, the screed should be moistened twice a day, protected from drafts and covered with polyethylene. However, a long laborious process is relatively inexpensive.

The main advantages of a cement-sand screed are the porosity of the structure, which provides excellent sound and heat insulation, minimal shrinkage due to the limited amount of water and the availability of manufacturing materials. And how to make such a screed with your own hands and technologically correct, we will tell in the material:https://floor.expertexpro.com/en/viravniv-stazhka/cementno-peschanaya-styazhka.html.

Laminate can be laid on a screed if its moisture content is not above the limit of 5%. If humidity does not meet these conditions, lay a waterproofing layer and lay the cork backing.

Dry screed GVL, plasterboard sheets, particleboard, plywood

To level the cement floor using the dry screed method, lags are installed, that is, a structure is constructed from the timber, to which gypsum sheets, plywood, chipboards and similar material are attached:

- Marks are set for the planned floor level.

- A waterproofing layer is laid on the rough plane.

- The floor system on the logs is being built, the rules for its installation are described in the corresponding article.

- Logs, previously horizontally aligned by placing chips and squeezing excesses, are attached to the base floor with dowels or anchors.

- One or several layers of the material selected for the dry screed device are laid on top of the log-lag. Fastening sheets and panels is performed with self-tapping screws.

Note. To simplify and speed up the construction of the floor on the logs, prefabricated systems with regulatory devices will help.

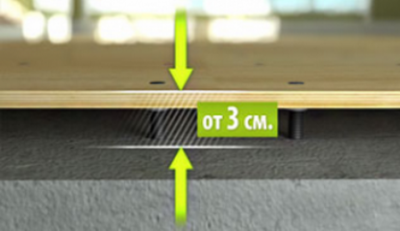

The technology is applicable if the height of the ceilings allows it to be reduced by 10 cm or more. The advantage of the technology is the ability to lay the laminate immediately after finishing work.

Wood floor leveling

The wooden floor with tangible defects and failures needs to be disassembled, replaced with damaged elements, nailed the shaky boards firmly, driving the fastener caps deep into the material. Then you can:

- to build a dry screed on the logs by analogy with the method described above, using a vapor barrier material instead of a waterproofing layer;

- lay plywood, gypsum plasterboard, plasterboard sheets directly on the wooden floor;

- hinge the wooden floor.

Looping - a leveling method applicable exclusively to surface treatment of wood. Manually cycle too long and hard enough. It’s easier and wiser to rent a loop machine. It will remove the upper uneven layer, form the technical conditions required for laying the laminate. Then the surface is cleaned of wood dust, putty and put the soil.

The most budgetary way to level a wooden surface is to putty with a mixture made of sawdust and PVA. By technology, it resembles the cement-sand leveling method, but before laying the laminate on a sawdust-cool screed thin plywood sheets.

On how to level the floor with plywood, see our website:https://floor.expertexpro.com/en/viravniv-stazhka/vyravnivanie-pola-faneroj.html. Step-by-step instructions for performing work.

Information on how to level the floor will help determine the priority screed technology. The owner himself is free to decide what is more profitable for him: reducing costs, minimizing labor costs or increasing the pace of repairs. Knowing the predominant sides of each of the alignment methods guarantees a competent choice of the most appropriate option.

3 comments