Electric underfloor heating in a wooden house: hovercraft system

The construction of a heat supply system mounted in the floor of a house made of lumber is argued by a mass of weighty factors. Water or electrical equipment located under the final floor does not affect aesthetic criteria, eliminates the need to install radiators and pipes required to connect them. However, in order to arrange a warm floor in a wooden house, it is necessary to take into account the specific features of the wooden structure and comply with the rules for installing these heating systems in them. We will try to reveal these nuances today.

The technical system "warm floor" in a house made of wood completely copes with the heating of the building. With rational use and the presence of a heat-insulating layer, it can significantly reduce significant costs in the heating season. Failure to install batteries and pipes provides the opportunity to fully utilize the useful interior space. The peculiar charm of the interiors of wooden houses is preserved, not spoiled by the presence of equipment not compatible with the wooden surroundings.

Content

Which system is better to do - on water or electricity?

The construction of houses made of wood involves the use of two types of materials for floors: concrete slabs and wooden beams. Most often, wooden beams are used, since they do not reduce the heat engineering parameters of wooden structures and do not force them to increase the bearing capacity of the fundamental foundation.

Both types of floors are compatible with two existing systems of underfloor heating, the choice of which depends only on the individual preferences of the owners and on the required power of the heating equipment. In the ceilings of wooden houses can be installed:

- A metal-plastic pipeline system with an agent circulating through it - hot water.

- A conductive system represented by mats, cable or infrared heating film.

Most owners prefer conductive systems, despite the fact that there are many adherents to the water equipment. Plastic pipes above the ceilings, they are mounted mainly in bathrooms, which is justified by the convenience of their connection to the installations supplying hot water. However, light weight, ease of installation, minimal energy consumption and productivity of conductive systems convinces reasonable owners that it is better to carry out heated floors in a private house using an electric cable.

It should be remembered. The specific power of the heating cable located above the wooden beams must not exceed the limit value of 17 W / m. The specific power limit of the “warm floor” electric system in a timber or log house is 130 W / m2. Exceeding is a violation of the rules specified in the fire safety requirements; it creates a fire hazard.

The electric "warm floor" with proper installation will provide ideal comfortable conditions and excellent heat transfer.In addition, the latest equipment modifications are equipped with devices that control the level of moisture, which helps to extend the operational life of wooden structures.

Technical requirements for the installation of an electrical system

Owners who decide to arrange an electric underfloor heating in a country house should follow the rules, the observance of which will eliminate the likelihood of risky situations and problems during operation.

Do not want to extensively remodel the floor for the installation of water or electric heating? The output can be a film infrared warm floor, about which you can read here:https://floor.expertexpro.com/en/tepliy-pol/plenochnyj-infrakrasnyj-teplyj-pol.html.

When installing a conductive system, a warm floor, you need to remember that:

- Laying the heating cable should be uniform, providing equal parameters on all sections of the floor.

- The presence of a thermostat equipped with temperature sensors for the entire floor structure and air cushion eliminates overheating and spontaneous ignition. The limit value, automatically regulated by the thermostat, for wooden floors 40 ° C.

- Need waterproofing, eliminating the effects of moisture, as it is an excellent conductor.

- The thickness of the flooring constructed from hardwood (beech, oak) should not exceed 24 mm, the thickness of lumber from pine or larch is not more than 22 mm.

- It is not recommended to lay the electric cable in areas where heavy furnishings are located, the weight of which during long-term operation often leads to damage to the electric wire.

It is unreasonable and undesirable to lay synthetic or natural carpet coverings covering the entire area on top of the warm floor system. They will perform the function of insulation, due to which the generated heat will not fully enter the heated rooms.

We decided to make ourselves an electric heated floor, but can’t decide which side to approach the task? Our article will help you with this:https://floor.expertexpro.com/en/tepliy-pol/elektricheskie-teplye-poly.html.

Rules for installing the system in a wooden residential building

A powerful concrete screed unnecessarily weighs the weight of a house from a log or timber. Therefore, in wooden buildings, a warm floor is mounted mainly on an “air cushion”.

Laying the subfloor and the device system underfloor

The order of the work is as follows:

- The floor is cleaned of dirt, debris, dust.

- Filling of cracks and gaps is carried out, it is carried out only with the use of compounds designed to seal defects in wood.

Note. Foam is not compatible with the “underfloor heating” system due to the high insulation characteristics that impede the passage of heat generated by the equipment.

- The laying of guide pine beams is carried out (material length 2 m, size 40 × 40 mm). Guides are attached to the rough surface with self-tapping screws.

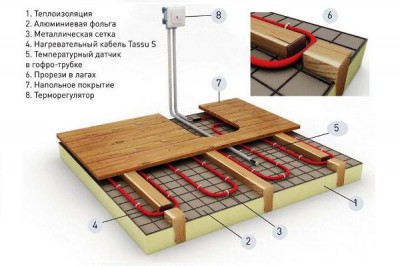

- Then the thermal insulation material is laid. Most often, it is foil foamed foam that performs two functions: insulation and reflection of the heat flux supplied by the heating cable. The material is laid in the spaces between the support bars.

- A galvanized mesh is placed above the insulating material.

- In parallel with the guide rails, a power cable is laid at a distance of about 10 mm.

- At the points of intersection of the support bars with a cable, cuts are made, deepening them to the level of the insulation layer. In each cut you need to put a metal foil.

- The cable is fastened to the bars using a mounting tape. If there is a need to attach the cable to the grid, use clamps.

A detailed comparative review of options and technologies for installing underfloor heating systems on our website:https://floor.expertexpro.com/en/tepliy-pol/kak-sdelat-teplyj-pol.html.

A little attention! The minimum height of the "air cushion" when installing a warm floor in a wooden house is 30 mm.

We can assume that the heating of the house with underfloor heating is organized, and proceed with the construction of the final floor.

Laying the floor

Most often, the finishing floor in a house made of logs or beams is arranged using milled boards equipped with elements of a spike-groove lock connection. The minimum width of the material is 9.8 cm, the maximum is 14.5 cm, and the thickness is 3 - 4.4 cm. Milling boards with a longitudinal recess on the lower surface provide natural air circulation in a complex floor system. Laying of the final coating can be done with tongue-and-groove boards with a fold or rail, the back of which is not processed. But the laying of such material requires experience, skill and attention from the contractor, so milled lumber is often chosen.

Tip. It is advisable to use lumber that has passed chamber drying for the installation of the finish floor. Before fixing, the final floor must lie over the working electrical system for two days, after which the boards need to be fixed.

Thorough adherence to the technical rules for the installation of a warm floor in a wooden structure will eliminate the threat of fire, costly heat loss, and premature failure of the conductive system. Proper installation of the heating circuit guarantees comfort and safety.

2 comments