How to insulate the floor in a wooden private house: choice of insulation and technology of work

Despite the excellent insulating qualities of wood, a floor constructed from lumber must be insulated. Without thermal insulation, the design does not cope with the role of a barrier that completely prevents heat loss. As a result of the shifts characteristic of natural organics, gaps appear between the elements.

Due to the difference in external and internal temperature, condensation forms on the surface of the beams and logs with unchanged consequences - fungi and mold. To eliminate the entire list of the listed troubles will help the insulation of the floor in a wooden house, for the implementation of which special technological schemes are used.

Content

Optimal insulation for wooden floors

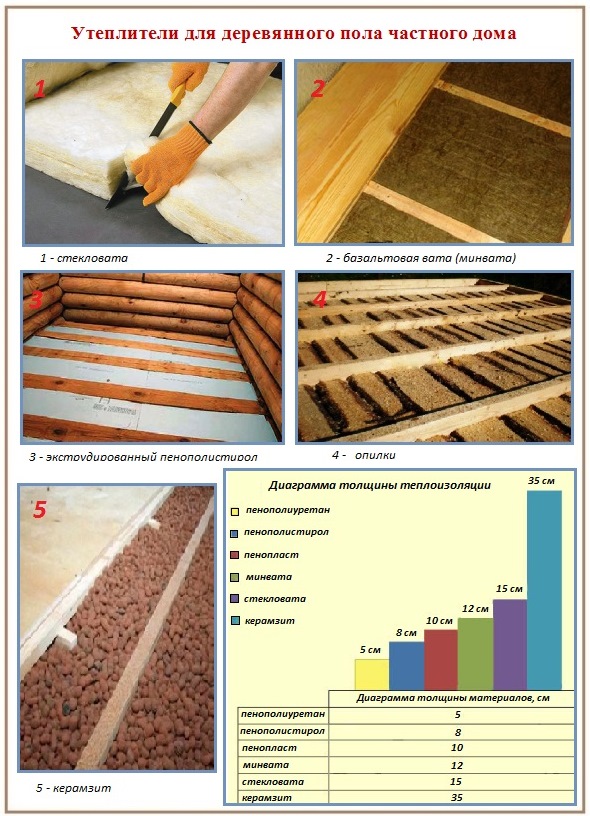

It is pointless to discuss the topic of the best material for thermal insulation of a wooden floor. Practically everything is applicable, starting from the old-fashioned dry foliage, ending with expensive vermiculite. The floors in wooden houses are insulated with loose options for thermal insulation, mats and slabs.

Since the list of requirements for any insulation stably means lightness, minimal water permeability, long-term, operational safety, all these qualities are quite suitable for builders and owners of wooden houses.

The choice mainly rests on the financial capabilities of the owner, on the type of foundation and on the way of laying. Owners who are not limited in funds will be able to purchase progressive, easy-to-fit materials with detailed instructions on how to insulate the floor in a private house without involving builders and with an accurate indication of the thermal characteristics of the factory product on the package. If you want to save money, you will have to tinker a lot with traditional insulation schemes.

Heaters for thrifty owners

Independent home masters who do not want or are not able to invest significant amounts in insulation can use as a heat insulator:

- dry sawdust, pleasing at the lowest price, but requiring reliable waterproofing on both sides of the insulating layer due to the tendency of the material to actively absorb moisture;

- sawdust granules, which are a more practical option, treated with an antiseptic and flame retardant;

- attractive slag, but used mainly in floor heating schemes on the ground;

- expanded clay used to create a heat-insulating layer of considerable power, since its optimum thickness for our latitudes is considered to be 30 cm;

- simple mineral wool without foil and corrugated shells that increase thermal performance;

- fiberglass-based insulation made from slag;

- polystyrene foam, in need of measures to protect it from the encroachment of rodents and from fires.

Subject to the rules of thermal insulation using the above materials, heat leakage through the lower floor will be excluded. However, laying them will require impressive labor effort.

Modernized expensive heaters

If the owner of a suburban property does not have the main task of how to insulate the floor in a wooden house with insignificant expenses, then he has at his disposal:

- Vermiculite is a hydrated mica processing product with excellent insulating properties and long-term operational life;

- Penoplex - extruded polystyrene foam produced in the format of plates with increased strength and excellent waterproofing properties;

- Various modifications of heaters with the brands Ursa, Thermolife, Isovent, Penofol, Isolayt and others, which are mats and plates with bases made of expanded polystyrene, glass wool and basalt analog, optimized by increasing wear resistance, minimizing water permeability, applying foil shells to reflect heat rays back and other methods.

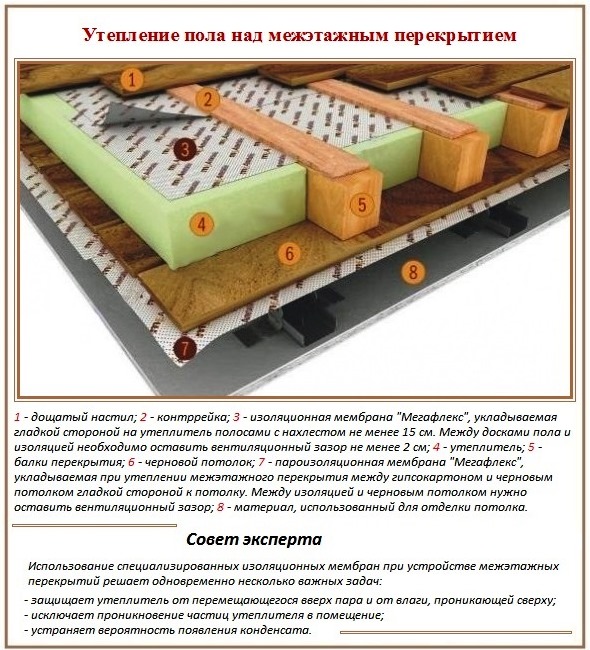

In case of minor heat leaks, it is possible to insulate a wooden floor with ecowool or polyurethane foam, but without special equipment it is impossible to blow these materials.

This is a significant minus, and the plus is the creation of a dense water-repellent insulation layer that does not require a device to protect the heater from steam.

Schemes for insulation of wood floors

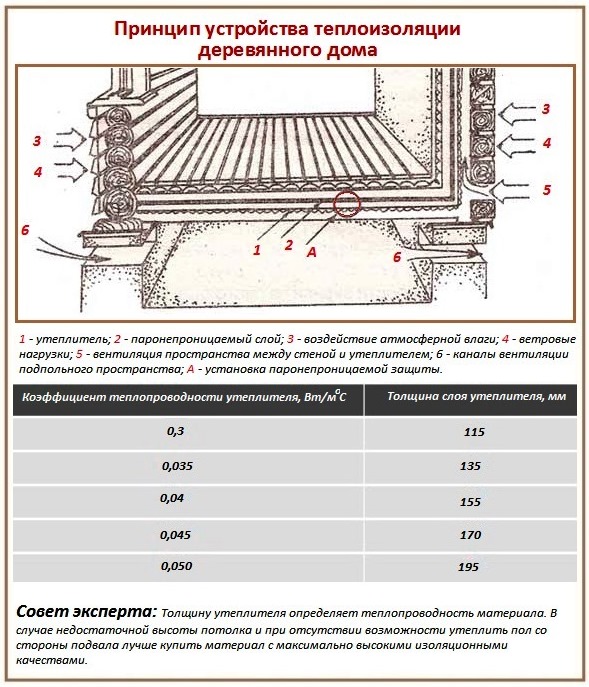

SNiP numbered 23-02-2003 contains tables with standard values of heat transfer resistance and the rules of heat engineering calculations, focusing on which it is necessary to select the thickness of the insulation.

Without going into details of the laws of heat engineering, builders recommend constructing an insulated floor above a cold basement in a middle strip with a thickness of 12 cm, in the northern regions 20 cm thick, and to add 8 cm of thermal insulation in case of heat leaks in case of heat leaks.

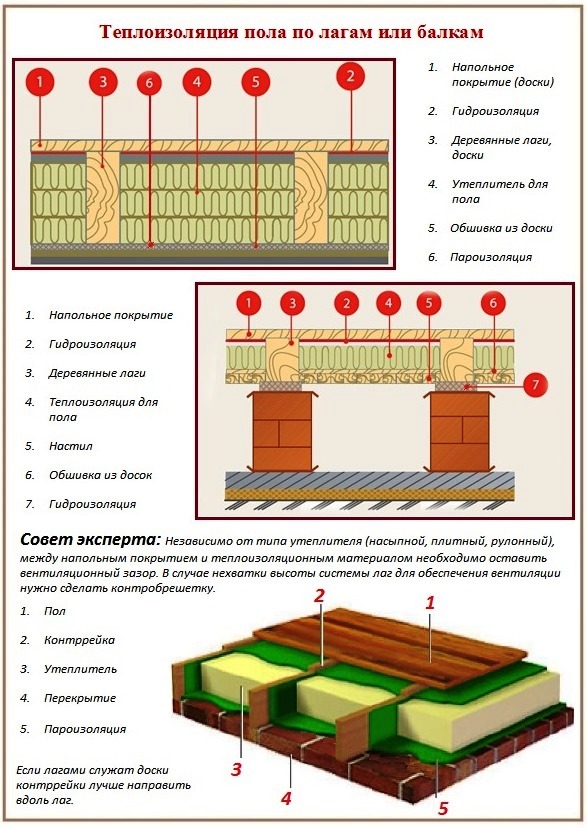

The priority of warming a wooden floor in a private house is directly its construction of beams and a log system, which allows filling expanded clay, mineral wool or polystyrene with the space between the supporting elements.

The general principle is to build between the lags a kind of "boxes" in which the heater is poured or laid. The work is simple and if you want to show zeal, it is completely feasible with your own hand. The main thing is to choose the right technological algorithm, according to which you can warm the house quickly, correctly, efficiently.

Thermal insulation of the floor above the low underground

This is the most time-consuming method with the need to dismantle the flooring, since the limited dimensions of the subfloor do not allow attaching thermal insulation from the bottom to the lags. The work is carried out in the following sequence:

- We dismantle the skirting board and floorboards, not forgetting to sign the floor elements for the purpose of operational back laying.

- We carry out an audit of wooden components. We cut out all the dubious sections of the lag and install a beam with equivalent sizes instead. We increase with the help of boards attached to the right and left of the log, bolted with galvanized self-tapping screws.

- Hem to the lower edge of each log, again on both sides of the block. It will serve as a support for the skull flooring.

- According to the distance between the logs, we procure inexpensive lumber for the construction of the rough floor. Unedged boards need to be cut into segments 1-2 cm less than the installation step of the lag, so that the details of the cranial flooring fit freely.

- We construct the rough floor by means of the banal laying of the prepared scraps of the board. Builders do not advise tightly docking them, as the characteristic movements of the wood will turn the "laid back" laid cranial floor into a ridge of steps and knolls. Attaching trim boards to the support bar is also optional, and not recommended.

Note. Further actions depend on the degree of saturation of the underlying rocks with water. According to the technological guidelines, a draft floor arranged between the lags together with them - with the lags, needs to be covered with a layer of vapor barrier.This barrier will protect the heater from steam rushing up from the earth's surface according to the laws of physics, but will not prevent the condensate from leaving the thickness of the material. However, if the house is built on a site with a high mirror of ground water, instead of a vapor barrier membrane, it is better to use waterproofing - roofing material or glassine.

- We lay the insulating layer with a continuous sheet with "approaches" to the walls of 10-15 cm. As a result, something like a pallet should come out. Rolled materials must be laid with an overlap and tape strips connected. For reliability and convenience in future work, you can periodically fix the insulation carpet with a stapler to the logs and to the walls.

- The voids formed between the lags are filled with the selected insulation so that between the upper edge of the lag and the surface of the loose, rolled or plate material, approximately 2 cm is left for ventilation. If the thickness of the insulation does not allow to leave a ventilation gap, that is, the surface of the insulation is flush with the upper plane of the log, it is necessary to build a counter grill. Nail the rail with a step of 40 cm along the lags "in the cross" in their direction.

- Again an insulating carpet made of glassine or a diffuse membrane to protect against moisture tending down. In the case of a counter-lattice device, the insulation should be under it.

- At the end, we mount the floorboards at the numbers indicated on them in the reverse order, put the plinth, cut the insulation along its edge.

Of course, in order not to think about how and with what to properly insulate the floor in a wooden private house, the installation of thermal insulation should be taken care of during the construction period, but the deficiency can be eliminated by the above method and after.

Elementary warming of the cold underground at the construction stage can be done by backfilling a layer of expanded clay covered with a soil base covered with geotextile. A more complex option is to install on the beams pre-knocked down by the size of the floor box-shields filled with thermal insulation.

The method of warming the floor above a high cellar

The principle is similar, but there is much less action, since there is no need to dismantle the floorboards, and the algorithm of operation is the opposite:

- With a stapler, we fasten the waterproofing layer to the tested, repaired beams from the side of the unheated underground.

- Support bars or thin slats, by analogy, are nailed to the side faces of the beams from below. In moist basements, instead of a bar, it is advised to use a galvanized profile. These support elements will have to hold only the weight of the piece of thermal insulation.

- We cut the mineral wool so that the width of the piece is 2-3 cm larger than the step between the lags. Then, when the heater is installed in the “window” intended for it, it will stand upright, temporarily fix, and will not interfere with the fixing of the subfloor. Bulk materials, of course, are not used in this scheme, and the plates will need to be mounted with assistants: someone holds the material, someone fastens the rails to support it.

- From below, we fix the insulating membrane with a stapler.

- Sew to the beams across their direction of the subfloor board.

To protect from frisky rodents, you can place a metal mesh with small cells between the subfloor and waterproofing.

Double sex device

The method is applicable if the height of the ceilings allows you to reduce this important parameter by 12 or 20 cm. True, the owners, puzzled by the problem of how to insulate the wooden floor in a private house with minimal dimensional changes, can purchase a ready-made set of false floors with the Knauf brand, which allows to reduce the height only 5 cm.

Homeworkers who don’t have a Knauf DIY kit need:

- remove the skirting board, repair the floorboards and fill the slots with mounting foam, sawdust with carpentry glue or soaked paper with paste;

- set logs with a step between them of 0.6-0.7 m, max 0.9 m;

- measure the height of the upper planes of the log with a spirit level, in case of excess, cut off the excess with a plane, eliminate the shortage by lining the roofing felt or wood chips under the beam;

- to lay steam or waterproofing with a continuous cloth with approach to the walls;

- fill the space between the logs with expanded clay, basalt wool, expanded polystyrene or other heat-insulating material, not forgetting about the ventilation gap;

- cover the insulated floor with another layer of insulation;

- to lay a board, plywood, GVLV or any similar material;

- in the final, the floor covering is laid and the baseboard is installed.

Regardless of the choice of the technological scheme, the floors of pile foundations, as well as their bored and screw modifications, must be protected from blowing by a windproof barrier. It is located on the outside of the insulation system.

In fact, there are much more ways to insulate wooden floor structures in a private house than we could bring. It’s just that all advanced technologies and innovative materials are based on general rules and schemes. They are adjusted to the climatic and geological features of specific areas, complement or reduce the number of layers in the constructive floor cake.

Having familiarized with the principle of insulation, it is easy to independently develop your own version of thermal insulation and implement a home-made project.

12 comments