Vapor barrier in a wooden house: choosing a vapor barrier and laying instructions

The floor in a wooden house is a multilayer structure, an important part of which is vapor barrier. It allows you to protect the insulation, boards and floor logs from steam, which, penetrating underground, condenses and turns into a full-fledged liquid. And since something is constantly being cooked, washed and washed in any residential building, the floor without vapor barrier risks becoming a source of constant dampness. This, in turn, leads to the appearance of fungus, mold and rotting of wooden structures. The vapor barrier of the floor in a wooden house will help to avoid these bleak prospects, extend the life of the building and increase comfort in the room.

What materials are used to vapor barrier the floor?

It is convenient to use various films as vapor barrier materials for a wooden floor, which, due to their structure, do not allow steam and water to pass through. You can choose the type of vapor barrier from the list:

1. Plastic film

The most famous and inexpensive vapor barrier is polyethylene film, which is sold in wide rolls. Since the polyethylene webs themselves are quite fragile and easily torn, they are reinforced with fabric or thin reinforcing mesh.

Reinforced films can be perforated and non-perforated. The first type due to microholes is characterized by a sufficiently high vapor permeability (Sd = 1 - 2 m). This means that a certain amount of steam perforated films pass. Therefore, in wet rooms, such films are more often used in a waterproofing system. Unperforated polyethylene with vapor permeability indices Sd = 40 - 80 m, which serves as an excellent barrier even for finely dispersed steam, is a completely different matter.

2. Aluminum laminated plastic film

There is another type of film - polyethylene canvas with an aluminum reflective layer. In addition to high vapor barrier properties (Sd = 200 m), this material also has heat-insulating qualities, reflecting infrared radiation and keeping heat indoors. Such vapor barrier of a wooden floor is most often used for very humid or hot rooms, where it is important to maintain the existing microclimate. It can be kitchens, showers, baths and saunas.

3. Polypropylene film

Compared to polyethylene, polypropylene is more durable. Materials with an anti-condensation layer, which have low vapor permeability (Sd = 50 -100 m) and prevent the formation of condensate on the inner surface of the film, are considered to be especially high-quality.

Polypropylene films may not have an anti-condensation layer, but in this case, condensation often forms on their surface, which is in close proximity to the insulation.

Which side should the vapor barrier be fixed?

The device for vapor barrier of the floor should be on strict technology. One of the most important points is which side the insulating film will be laid on. If you do not pay due attention to this item, then the vapor barrier will not work. The basic rules for installing a vapor barrier are:

- When using a double-sided film, you need to lay it with a smooth surface inside the “pie” (for insulation), and with a rough one - outward, towards the pair. The rough side will keep steam and condensation on itself, preventing moisture from entering the insulation.

- Polypropylene films with a single-sided laminated coating also have a smooth surface to the insulation, and wicker - towards the room.

- Foil films tend to reflect infrared thermal radiation from themselves. Therefore, it must be laid with the aluminum side outward, in the direction of the room.

These styling principles work almost always. But manufacturers of modern vapor barriers still reserve the right to change this order. For example, it is recommended to mount the well-known vapor isolator Isospan B with the rough side to the insulation, and the smooth one outwards. Therefore, always, before starting to lay out the roll of the vapor barrier, read the instructions for its use.

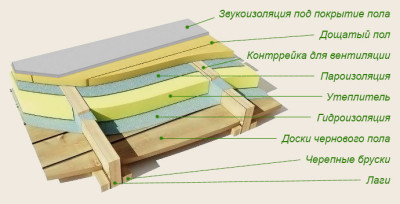

The place of vapor barrier in the floor "pie"

The main role of the vapor barrier film is to prevent the penetration of wet steam to the wooden floor structures and insulation. Therefore, vapor barrier is always laid between the finishing floor and the insulation. Usually, a second vapor barrier layer is also provided in the floor structure - it is placed behind the insulation, between it and the subfloor. This layer prevents the penetration of moisture and steam from the ground. However, this vapor barrier layer is sometimes replaced with a waterproofing film or membrane. The bottom layer of isolation is especially relevant on the lower floors of wooden houses, the rough floors of which are located directly above the ground or above moist basements.

Step-by-step instructions for vapor barrier

1. Preparation of the rough floor

Before laying the vapor barrier on the floor, it is necessary to treat all wooden base structures (boards, logs, cranial bars) with antiseptic compounds against rot, insects and fungi. In the event that it was decided to arrange a new vapor barrier in an existing floor covering, clean floor boards, as well as old heat and vapor insulating materials, are removed. All garbage and dust are removed, the wooden elements of the subfloor are primed with antiseptics and put in place.

2. Laying the vapor barrier on the floor

The first layer of vapor barrier film is laid for vapor and waterproofing, that is, to prevent moisture and steam from entering the insulation from the ground.

Roll a vapor barrier film unfold and lay the canvas on the floor frame. Separate strips overlap by 15-20 cm and are connected to each other by means of a special double-sided tape or mounting tape. This solution eliminates the occurrence of cracks and gaps through which unnecessary moisture can get into the insulation. The web is attached to the lags with a stapler or galvanized nails.

3. Laying insulation

On top of the film, between the lags, a heater with a minimum thickness of 50 mm is laid. It can be polystyrene mats, polystyrene foam, mineral wool. The insulation must fit snugly to the lags and vapor barrier film, without creating cracks and gaps.

4. The device of the second layer of vapor barrier

The second layer of the film plays the role of direct vapor barrier, creating a barrier to wet steam coming from the room, and not allowing it to be insulated.

The film is laid on the logs in such a way that the ventilation gap between the vapor barrier and the flooring is maintained. Stripes of a film are connected among themselves by an adhesive tape or a mounting tape.

5. Flooring

Finish boards are mounted on top of the lag, onto which the final floor covering, for example, parquet, laminate, linoleum, etc.

4 comments