Electric cable underfloor heating system: from component selection to first start-up

Folk wisdom advises keeping your feet warm, your head cold, and your stomach hungry. If the last two recommendations are quite simple to implement, then the first often causes problems. Since warm air always rises, and the heating elements of the water heating system are much higher than the floor level, the latter is often very cold. It is especially difficult to warm the feet of residents of the first floors or the owners of private houses with poorly insulated foundations. The only salvation in such circumstances is electric underfloor heating.

Content

Advantages and disadvantages of the electrical system

Like each of the existing heating systems, underfloor heating has its advantages and disadvantages.

Advantages:

- The location of the heating elements under the floor surface provides the most comfortable heat distribution. And the control system allows you to set for each room separate values of the maintained temperature.

- The warm floor heats up much faster than other heating systems. This is due to its significantly less inertia. So, having come to a cold room, you do not have to wait long until it becomes at least a little warmer.

- Many manufacturers claim that the most durable are the electric "warm floors". The most famous companies give a fifty-year warranty on their products.

- Often laying the heating elements and the new flooring does not require dismantling the old one. If there is ceramic tile on the floor, it is not necessary to tear it off. In this case, it is recommended to use electric heating mats, which together with the new coating will raise the floor level by 1.5 cm.

- If for some reason the system still crashes, it does not need to be opened to repair the entire floor surface. With the help of special devices, the place of cable damage can also be detected through a concrete screed. After that, it is enough to remove several tiles and restore the damaged area using special couplings.

- Electric underfloor heating is absolutely safe. Even if the insulation of the conductor is damaged, the RCD (residual current device) will shut off the current supply.

Disadvantages:

- The main disadvantage of the electric floor heating system is the high consumption of electric energy. And the point here is not the cost of kilowatt hours, but the worn-out wires. The fact is that in many cities of our country the power supply system was designed and designed many years ago. And often the house wiring was mounted not much later. Over the past years, the level of energy consumption has grown significantly, and old wires can no longer cope with the load. So, before installing such a warm floor, it is worth checking whether your wiring can withstand the additional load.

- Like all electrical appliances, “warm floor” is the cause of the appearance of an electromagnetic field.However, it is necessary to mention that some scientists who took measurements of induction and field strength in rooms with electric floor heating claim that these indicators do not exceed the background values.

How to calculate the required power?

When the decision to install an electric underfloor heating has already been made, it's time to do the calculations. Only the area of the furniture-free area should be taken into account.

Floors as the main heating system

Please note that the area of the heated floor should not be less than 70% of the total area of the room. So, in a room heavily laden with furniture, such heating will not be effective. The specific power of the underfloor heating for normal heating should be 150 -180 watts. In addition, some features of the room should be considered.

So, on a glazed and insulated loggia or in a winter garden, the specific power should be greater than in the living room. As a rule, underfloor heating in the bathroom is also made a little more powerful. Owners of apartments on the first floors of multi-storey buildings should increase the specific power of the warm floor by 15% - 20% (due to heat loss caused by the cold basement).

Floors as additional heating

More often, such heating is used as an additional. Many use it in the bathroom, where you have to stand on the tile floor with bare feet. Sometimes underfloor heating is also used as “off-season heating” when the heating is turned off and the room is cool. In this case, the specific power of the system of 110-140 W / m is quite enough2.

Selection of heating system components

The main element of the underfloor heating is the cable, the choice of which determines the route of laying and the power of the system.

Resistive cable

Outwardly, it is indistinguishable from ordinary, but has completely different characteristics. If for the core of a conventional electric cable, manufacturers choose the material with the least resistance in order to reduce the energy loss to overcome it, then in the manufacture of a heating cable they do just the opposite. Most often, the core of the cable is made of nichrome, which has a very high resistance.

Decisive in the choice of cable is the value of its linear power (specific heat). For domestic use, this indicator ranges from 15 to 21 W / m. When choosing a cable, remember that the distance between the turns during installation should not be less than 5-6 cm - this is fraught with overheating, and more than 10-12 cm - otherwise, temperature differences will be felt on the floor. Based on these values, you should choose the linear power of the cable. That is, with a distance between turns of 10 cm, by 1 m2 you will need 9 meters of cable. With the required specific power of the system 140 W / m2 The calculation will look as follows:

140: 9 = 15.6 W / m.

At the same time, when laying cable sections at a distance of 5 cm from each other, the calculation will look like this:

100 cm (1 m): 5 (distance between sections of the wire) = 20 m - the required length of the wire.

140 W / m2: 20 = 7 W / m - the required linear power of the cable.

Note! There are single and two core resistive cables. Laying a system from a single-core cable is justified only in small rooms. This is due to the fact that both ends of this wire must be connected to the thermostat, and in a large room this need can greatly complicate the choice of route for laying the cable. A two-wire cable is connected to the network on one side only, which makes it the most convenient for laying in large rooms.

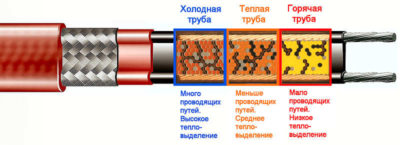

Self-adjusting cable

This is a two-core cable, both cores of which are made of material with low resistance. The role of the heating element here is played by a semiconductor polymer matrix. It is the properties of the semiconductor that allow such a matrix to carry out the function of self-regulation.

The use of this cable eliminates the possibility of local overheating and allows it to be laid under coverings such as laminate and parquet. Take into account the location of furniture is also not necessary. So this cable is ideal for lovers of frequent interior changes. The only drawback of the self-regulating system is the rather high price.

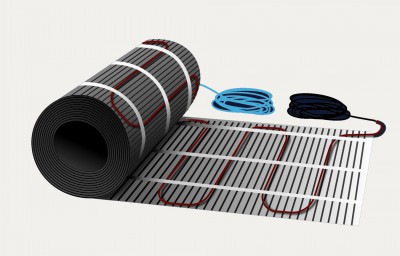

Heating mats

The heating mats are essentially the same resistive cable, only already laid by the snake and attached to the polymer net.

Thus, laying of an electric heat-insulated floor is much easier, but its price increases. The cost of mats is on average 20-50% higher than the price of a cable comparable in quality.

Thermostat selection

The thermostat is no less important part of the underfloor heating system than the heating cable. Non-programmable thermostats must be turned on manually. The adjustment of such a device can be either stepwise or resistor (smooth).

Programmable thermostats are much more sophisticated devices that maintain a constant temperature in the room. Some of them are equipped with timers that turn the system on and off at certain times.

Thermal insulation selection

To prevent heat being wasted on heating the basement or floors under the cable, it is necessary to lay a layer of insulating material. There are two ways to do this, each of which has its opponents and supporters. The first method involves the use of extruded polystyrene foam with a thickness of about 30 mm. Opponents of this method argue that raising the floor so does not make sense and are advised to use foil isol. To which supporters of EPSP say that in an alkaline environment of a cement screed in a few years the foil isol will collapse, which will lead to additional heat loss.

For those who decide to install a warm floor on their own, but who are afraid of mistakes in choosing parts suitable for each other, there are ready-made kits that include a cable, a thermostat, a tube for installing the sensor under the floor surface and detailed installation instructions.

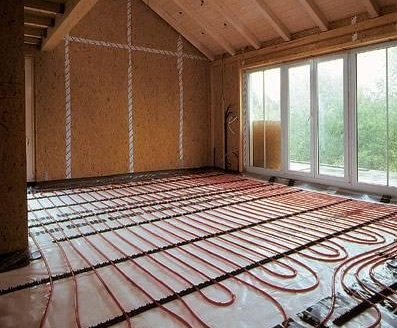

Quick Installation Guide

Installation and connection of the electric floor must be carried out with maximum accuracy so that the cable does not bend. In order to facilitate the process and not get confused, make a drawing of the heated area. Indicate on it the location of the cable, thermostat, coupler, end coupler and temperature sensor. When the drawing is ready - get to work:

- Cut through the wall from the floor to the level of the thermostat mounting to a 20/20 mm strob.

- Clean the area of the floor on which the cable will be laid.

- On the floor, in increments of 50-60 cm perpendicular to the direction of cable laying, fasten the mounting tape.

- Lay out the cable in accordance with the drawing and fix it on the mounting tape.

- Place the sensor in a plastic corrugated tube and place between the cable lines. Mounting tape and protective plastic tube must be purchased separately.

- Now you need to fill the cable with a homogeneous concrete solution (without stones) with a layer of about 5 cm. Wait until the screed is completely dry. This process usually takes about 30 days. Do not connect the system to the mains before, the concrete has not dried out enough.

- Connect the heating cable to the mains.

We offer you to watch video instructions for installing heating mats, as well as a conventional cable system:

No need to be scared if the floor has not warmed up immediately. Leave the system turned on for a day, and you will feel the desired warmth under your feet. Whatever you choose warm floors - electric or water, your house will certainly become more comfortable.

4 comments