How to choose the right linoleum for laying on a warm floor: the main criteria

As a coating for a warm floor, linoleum is not very popular. The reason for this is the strong opinion of consumers that when heated, it releases harmful substances - phenol, toluene, vinyl chloride, etc. Such a development of events is quite possible, but only under certain factors. For example, when using the wrong brand of linoleum or in case of non-compliance with the temperature conditions recommended by the manufacturer. If you approach the problem of choice wisely, then linoleum for a warm floor can be as successful a purchase as “traditional” tiles or parquet.

What types of linoleum can I use?

We are used to thinking that linoleum is a thin vinyl coating that is dominated by chemical components. But it is not so. In the modern market there are 5 groups of this material:

- natural (marmoleum) - completely safe, natural material, which is characterized by durability, fire resistance, antistatic;

- PVC linoleum (vinyl) - the most popular and inexpensive, when heated, it can emit an unpleasant odor;

- alkyd (glyphthalic) - produced on a fabric basis, has high thermal insulation properties. Over time (especially when heated) is able to noticeably deform;

- nitrocellulose (colloxylin) is a thin single-layer material with good moisture resistance, but a significant drawback is its rapid flammability;

- rubber (relin) - a two-layer linoleum containing rubber particles, bitumen, synthetic rubber. It does not tolerate heat and is rarely used in residential premises.

Judging by these characteristics, not all types of linoleum are suitable for laying on a warm base. The most optimal choice is natural linoleum, a little worse - PVC linoleum. Alkyd, nitrocellulose and rubber materials for coating on heated substrates are rarely used.

Option # 1 - Natural Marmoleum

If the budget allows you, give preference to natural linoleum. It is made from natural ingredients: linseed oil, pine resin, crushed cork, lime powder, natural dyes. Accordingly, when heated, this type of linoleum is not able to release harmful substances into the air. And this is the main argument in favor of marmoleum, as a coating for a warm floor. In addition to absolute safety, natural linoleum completely retains its dimensions when heated and is not deformed. It is fireproof and in case of fire does not contribute to the spread of fire. Marmoleum does not change its color over time and does not fade in the sun.

Option # 2 - vinyl linoleum (PVC)

Marmoleum, although good, is not yet very common on our shelves. Therefore, if you could not find it, you can get by with "little blood" - purchase PVC linoleum for the warm floor. It is best to use for these purposes not domestic, but commercial or semi-commercial types, which are distinguished by higher strength and better performance properties. Immediately discard the material on a heat-insulating base. It will prevent the passage of heat from the heating elements into the room, thereby significantly reducing the effectiveness of the underfloor heating system. Choose linoleum on a thin fabric basis or without it at all.Using vinyl linoleum, remember its synthetic origin. At first, even high-quality vinyl emits an unpleasant odor when heated, which disappears after a few weeks.

Important features of the thermal regime

In principle, in order to choose linoleum for a warm floor, you do not need to have special knowledge and understand the properties of the material. Coating manufacturers will tell you whether their products can be used for underfloor heating or not. How? By marking.

The permissible heating temperature is also indicated next to the marking sign - it must be observed without fail. For marmoleum, the limiting temperature is about 27 ° C; above this limit, its surface begins to soften, melt, and tear. Vinyl linoleum can heat up to 29-30 ° C, after which it can swell, deform or lose color. Also, almost certainly phenols and all kinds of unpleasant gases will be asked for an exit. To comply with the required temperature of the warm floor, you will have to purchase a high-quality temperature controller, which will automatically maintain the specified mode.

What type of warm floor is better suited for linoleum?

The choice of the underfloor heating system that you are going to cover with linoleum should also be treated responsibly. Warm floor can be:

- water;

- electric;

- infrared.

Water floor heating - This is a system of tubes through which the coolant passes - water. This option is rarely used in urban apartments that are heated by central heating. In addition, water floors will require a tie between the pipes and linoleum, which is undesirable for rooms with low ceilings.

AT floor heating system The main element is the heating cable, which also fits in the thickness of the cement screed. An electric underfloor heating is simpler than a water one, in addition it is characterized by more uniform heating over its entire area, which is very important for maintaining the dimensions of linoleum laid on top. However, the electric floor heats up quickly, which means that linoleum on its surface can easily be deformed. Therefore, experts do not recommend this type of heating system for linoleum coating.

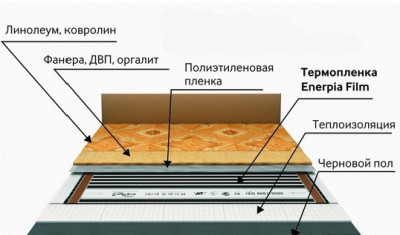

The last type of underfloor heating - infrared, which is a thin film with graphite strips-heaters. When connected to the mains, the canvas of the system begins to uniformly and gradually warm up, which eliminates the deformation of linoleum, possible with sharp temperature changes. Infrared floors can have a power of 60 W / m2 - 400 W / m2. If you decide to use linoleum, then use a canvas with a power of 60 W / m2 up to 150 W / m2. This is enough to warm linoleum to 27-30 ° C and at the same time maintain the original properties of the material.

Thus, in tandem with linoleum, the infrared warm floor is best manifested. It can be used for gentle, uniform heating, which does not change the appearance and operational characteristics of any type of linoleum. And finally, we want to present you an instruction from two videos on how to choose the right infrared heating system:

3 comments