General rules and tips for installing floor screed of any design

No matter how leaps and bounds the technical process progresses in our lives, certain things always exist and remain unchanged. And no matter what sphere we are talking about, the phrase “classic of the genre” is applicable to them anyway. Even to such a commonplace process as repair. Although the modern market for building and finishing materials is simply replete with a proposal of innovation. And in most cases, new substances, mixtures, and materials find their application in real life, but they cannot completely replace individual elements. Today we suggest you consider a topic such as a floor screed device. After all, everything is very simple: where, when installing the floor, the priority is the quality of the base, there can not do without a good screed.

A screed means an intermediate layer between a clean floor and a concrete floor. Moreover, the screed is the key to finishing floors - any top floor is ideally placed on an ideal foundation. Today, when laying floors, these types of screeds are used:

- Cement-sand.

- Dry screed.

Important! If it is planned that the floor in the room will be made of several types of floor coverings, then it is necessary to ensure that there are no differences at the joints of various materials.

Content

We select tools for work

The production of any work, including the implementation of sexual screed, involves the use of a number of tools, namely:

- Roulette.

- Line level.

- Rake is the rule.

- Knife.

- The hydraulic level, which can be purchased ready-made in a specialized store, or you can do it yourself. For these purposes, half-liter plastic bottles and a flexible hose are quite suitable. In his work, the principle of communicating vessels is laid.

- Putty knife.

- Paint roller for priming and waterproofing.

- Master OK.

- Construction mixer or drill with a special nozzle for the preparation of mortar.

- The capacity in which the solution will be mixed (up to 30 liters).

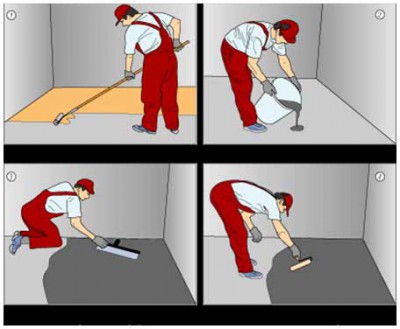

Prepare the base and determine the horizontal

In order for the cement screed device to work correctly and effectively, you first need to prepare a base for it. In principle, you won’t have to do anything extraordinary, and all the work will be to thoroughly clean the surface and repair possible cracks. Preparation of the base for any type of screed involves cleaning the surface of debris and eliminating its deformations.

Attention! Floor screed can be made on the ground. In this case, it is necessary to think over and protect the pipes or cables passing under the floor. Ideally, they should be placed in boxes.

Whatever type of screed is preferred, one cannot do without determining the horizontal. That is, you need to clearly measure where the zero floor level is. It is for this that the spirit level (hydraulic level) or a more modern device of a similar purpose is used - a laser level.

In the language of professionals, the zero level is called the "benchmark."It is taken out immediately in all rooms in which the screed will be carried out. As a rule, the height is chosen arbitrarily, more often it is 1000-1200 mm from the area of a clean floor. You can start beating in an arbitrary place, and from the first mark you can gradually transfer the mark to other rooms using the level or hydraulic level.

When leveling the floor, it is important to determine the zero level. We will describe how to do this using various tools in the article:https://floor.expertexpro.com/en/viravniv-stazhka/vyravnivanie-pola-svoimi-rukami.html.

Determine the maximum height of the base and the flow rate of the mixture

This stage is also extremely important, since the level of screed is set in the process and the average solution flow rate is calculated. To cope with this task, it is necessary to measure the length of the distance from the zero level to the currently existing distance, and in different places.

Attention! The more such control points there are, the more accurate the calculations will be, which means that the more perfect the surface of the completed screed will be.

At each measurement point, it is better to write the value obtained in chalk, or you can do this on a piece of paper, where you must first transfer all used points. By the smallest value, one can judge the highest point in a particular room, and by the largest - the lowest. The difference in these values will indicate the level of the height difference, which is very important for a really high-quality screed.

We expose guides - beacons

The guides, which are popularly called "beacons", are precisely the topic of reference points by which the screed is aligned. The evenness of the future gender literally depends on the correctness of their installation. As beacons, metal profiles or pipes are usually used.

Important! Lighthouses should be rigid and even, not bent and fixed without problems in the right position.

Installation of the guides is carried out at a distance of the length of the staff-rule. Lighthouses should be parallel to each other. And there are a lot of ways to install them, for example: on slides from a solution, with the help of adjustable screws, etc. To level the beacons, a ruler-level is used to ensure the same level height in all directions.

Cement-sand screed can be done independently. You can read step-by-step briefing on the work in the material:https://floor.expertexpro.com/en/viravniv-stazhka/cementno-peschanaya-styazhka.html.

Analysis of the main works depending on the type of screed

Cement and sand screed

The device of cement-sand screed is made on a stone, brick or concrete base to smooth its surface. In the production of works, a solution consisting of M300 cement and sand in a combination of 1: 3 is used. Measured in dry form materials are mixed with the addition of a certain amount of water. The result should be a homogeneous mass of consistency of thick dough.

Note! For 1 kg of cement, approximately 0.45-0.55 liters of water is taken. The resulting solution will correspond to the brand 150-200. The more water, the lower the mark.

Concrete screed

The concrete screed is installed using class B 3 foam concrete (minimum) with an average density of 600-1000 kg / m 3. In this case, they can be in the form of monoliths, and in the form of slabs. In addition, the use of lightweight concrete (perlite concrete or expanded clay concrete), which due to the cellular structure is endowed with high heat-insulating qualities, is allowed. However, such a surface will require additional leveling. If we talk about foam concrete, then the screed from them will have a more even surface, however, it is characterized by the appearance of cracks. And this means that you will also have to apply an additional layer of cement-sand mortar on top.

In some cases reinforced concrete screedthat will improve its operational properties and will minimize cracking. Reinforcement is of two types:

- Extended armature - volumetric frame, metal mesh, cpvs mesh, composite mesh.

- Dispersed materials - fiber made of polypropylene, steel, glass, basalt.

Dry screed

The dry screed device is made using dry backfill, which is covered with durable sheet materials on top. They are called “dry screed”. Already on it is laying the final floor. Today, the market offers a huge amount of materials for dry screed. And in each case, it is determined which one will be the most appropriate. The choice primarily depends on the type and quality of the top finishing flooring.

Laying a dry screed can be done not only on floor slabs, but also on floors with lags. In principle, this technology in our territory has been known for a very long time and is considered classic.

Dry screed - this is one of the fastest ways to make an even base for the finish coating. Learn how to do it yourself, in the article:https://floor.expertexpro.com/en/viravniv-stazhka/suxaya-styazhka-pola-svoimi-rukami.html.

Note! Recently, the leading manufacturers of building and finishing materials offer a comprehensive solution to the issues of dry screed. Thus, KNAUF and OPTIROC dry screeds enjoy good consumer reviews.

Semi-dry screed

A semi-dry screed device involves the use of a cement-sand mixture, the mixing of which takes place directly at the construction site. The main condition is the minimum amount of water, which, in accordance with the technology, is involved only in the hydration of water. After preparing the mixture, it is laid on the prepared surface and thoroughly rubbed. For these purposes, a special trowel is used, the so-called "Helicopter".

Important! Semi-dry screed allows you to achieve a perfectly flat surface, which will avoid additional costs for leveling the surface. On it you can immediately lay tiles, parquet, laminate or linoleum.

Summary

In the framework of this article, we tried to present a characteristic of all types of floor screeds that exist today. After familiarization, it remains for you to choose the one that will be most suitable for solving your problems. In order to understand in more detail the process of performing the screed directly, we suggest that you familiarize yourself with the training video clip:

3 comments