Choice and rules for using damping tape for floor screed

Damper tape for screed - one of the most important elements from the group of auxiliary building materials. It is widely used in the arrangement of "floating floors" and effectively helps to prevent cracking or premature destruction of the concrete base.

Content

What is damping tape for floor screed

A damper in the form of a tape is a kind of vibration damper, its absence causes expansion of the screed with temperature and other external changes, which can become the main cause of damage to building elements.

Material of manufacture, why used

The damper in appearance resembles a strip, for the manufacture of which modern polystyrene or polyurethane foam materials are used, supplemented by an adhesive composition. Due to the physical qualities of the feedstock, the finished tape acquires a dense foam structure that can easily cope with long-term floating dynamic loads.

A special screed arrangement tape can also be called a buffer, edge, compensation. And its main name comes from the German word Dämpfer, which translates as "silencer".

A high-quality material is distinguished by neutrality and complete chemical independence from the characteristics of the working medium, and when interacting with other materials or when changing temperature indicators it does not emit extraneous odors. An equally important quality is the presence of zero hygroscopicity, which is ensured by the complete absence of pores for moisture accumulation and the formation of mold colonies.

Due to its worthy flexibility in the molecular bonds of polyurethane foam materials, it has sound-absorbing qualities and effectively dampens even significant transmitted vibrations. Produced in accordance with a special technology and using foamed polyethylene raw materials, the material is intended for a multiple process of compression and expansion. This allows the concrete screed to "breathe" and many times increases the durability of the base.

Advantages of the buffer tape

All modern and high-quality compensation tapes have a huge number of very important properties, which are determined by the main technical characteristics of such auxiliary building materials. The most significant advantages of the application are presented:

- low thermal conductivity;

- good sound absorption;

- increased level of water resistance;

- resistance to sharp and frequent changes in temperature indicators;

- durability subject to installation rules;

- complete environmental safety throughout the entire period of operation.

Due to the advantages listed above, polyethylene edging tapes are widely used in sealing existing gaps, and are also actively used as a separator between floors and wall structures.

Types of Damper Tapes

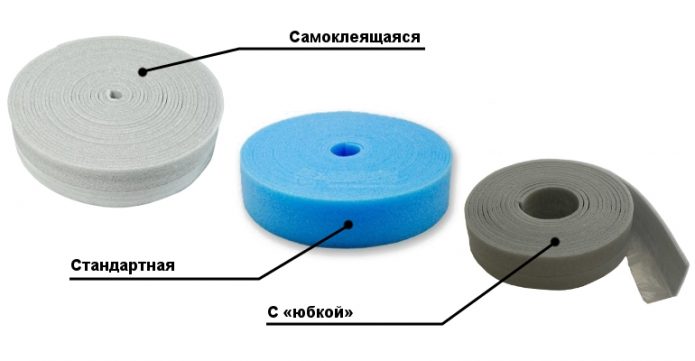

Available in several versions: standard look, having a "skirt" and self-adhesive.

With the right choice of the type of material, it is possible not only to compensate for the expansion of the screed and reduce heat loss through wall structures, but also to minimize noise and vibration, significantly improving sound insulation in the room.

Standard

A direct type buffer tape that does not have an adhesive layer. Fixing such auxiliary material to the walls, as a rule, is carried out by means of double-sided tape or special adhesive.

A feature of the use of a standard compensation tape is the need to perform mandatory preliminary and thorough preparation of all surfaces involved in the work. Even the smallest debris and dust must be removed.

With skirt

Tape "with a skirt" or "with an apron" has a characteristic feature - the presence of a kind of "skirt" made using a thin, but rather strong glued material. Such a part during installation neatly straightens on the floor, due to which it provides full sealing of all joints.

A distinctive feature of this option is the presence of a standard braid with a three- or ten-centimeter addition at the bottom, which is laid on a plate base, due to which additional sealing of the walls and floor is carried out.

Self adhesive

The back side of the self-adhesive product is equipped with a convenient adhesive strip, which has a special protective substrate in the upper part. Such protection must be gradually removed during installation.

According to experts, self-adhesive edge tapes are characterized by economical consumption and maximum ease of use, which makes this option attractive when arranging a concrete screed.

How to choose

With an independent choice, it is very important to pay special attention to several basic, most important parameters of this auxiliary building material:

- absolute integrity of the material;

- the complete absence of any deformation on the tape;

- the material should be even and accurate;

- the protective backing from self-adhesive tapes should not go away.

Damaged tapes must be discarded immediately. It is important to pay attention to the appearance of the material and the density of the roll, the absence of delamination and cracks. It should be noted that high-quality material cannot be too cheap and is not sold at a significant discount due to the non-marketable appearance.

If you are going to buy a compensation tape, pay attention to the presence of a special “line” - this is convenient when cutting off excesses that exceed the level of screed.

Material requirements

The basis for a high-quality edging tape is, as a rule, polyethylene foam raw material, which is a chemically neutral, practically non-combustible and environmentally friendly material having a characteristic closed cellular structure. It is this type of source material that is distinguished by worthy heat and sound insulating qualities, good moisture resistance, and also increased resistance to direct sunlight.

The tape should be stored in dry rooms at room temperature.

Roll Size and Length

Currently, there are several sizes, according to which foreign and domestic manufacturers produce compensation material. The best option is considered to be products having a width of the order of 150 mm with a thickness in the range of 4-10 mm, which are sold in rolls of 50 m.

Table: main typical sizes of compensation tape

| Length (m) | Thickness (mm) | Width (mm) |

| 25 | 10 | 100 |

| 11 | 10 | 150 |

| 11 | 10 | 100 |

| 25 | 10 | 100 |

| 50 | 10 | 150 |

| 20 | 8 | 80 |

| 25 | 8 | 100 |

The width of the material, as a rule, is selected taking into account the thickness indicators of the future concrete screed. When roughing a concrete screed, it is sufficient to use a tape having a width of 100 mm. The construction of a thickened concrete screed requires the use of a strip with a size of about 150 mm. The formation of a wall weld with the necessary parameters involves taking into account the area of cement pouring under the conditions of possible temperature differences characteristic of the premises being equipped.

When choosing a model, the operating conditions must be taken into account. So, for a warm floor, it must be heat-resistant, since heating to + 65 ° C is possible.

Manufacturing companies

Experts recommend giving preference to products manufactured exclusively by trusted and reliable manufacturing companies, whose products are not only of the right quality, but also characterized by the availability of self-assembly and the longest possible life. The most common brands on the domestic market are Tilit-Super, Uponor and Wolf Bavaria Viles Band, Teploflex, Valtec, Energoflex Super and Uponor Minitec, Soundguard Band Rubber, as well as Knauf.

Table: traditional edge compensators and damper tapes of brands recommended by specialists

| Brand / manufacturer | Main advantages | Tangible flaws |

| Uponor minitec | The basis of the product is porous polyethylene. Corresponds to DIN 18560. Has an adhesive layer on the back and an apron made of polyethylene for airtight fixation on the wall and improved waterproofing | Pretty high cost of the product |

| TILIT Super | The basis of the product is foamed polyethylene. There is a protective apron on one side. It is laid along the walls of the room, used for heat seams and protection against heat loss through the walls of the room | Practically absent |

| Energoflex | It is used to compensate for expansion in screeds, including the installation of a "warm floor" system. There is a "skirt" that prevents the spreading of the pouring mortar under the edge of the tape | Not always convenient with screeds over 10 m2 |

| Knauff | The basis of the product is foamed polyethylene with the addition of a “skirt” of film polyethylene. The product provides high quality installation work, including the installation of bulk floors | Pretty high cost of the product |

| Valtec | Italian edging tape based on modern foamed polyethylene is resistant to moisture, UV and high temperatures | Practically absent |

| Soundguard band rubber | Universal type self-adhesive rubber compensation tape for vibration isolation in almost any type of floor | Sometimes additional application of special vibration-isolating washers SoundGuard Vibro Washer is necessary. |

Step-by-step installation instructions for the damper tape

Installation of compensation materials requires mandatory additional fixation, especially when using products that do not have an adhesive base. As an alternative method of fastening, you can use:

- masking tape - as a temporary fixation in the process of pouring screed based on concrete;

- construction stapler - when performing installation indoors, having walls based on foam and aerated concrete, as well as wood;

- liquid nails - the best way to fix it on walls that have too rough a surface.

Fixing using self-tapping screws or dowels is used in exceptional cases or in the presence of brick walls in the room, since such metal fasteners can tear the tape, cause a loss of its elasticity.

Technology for laying compensation tape when performing concrete screed indoors:

- Preparation of work surfaces with the most thorough cleaning of construction debris, dust and dirt.

- Laying the product from the corner of the room with the gradual unwinding of the required amount of material from the roll. When using self-adhesive tape during installation, the protective top layer of the substrate is removed. Standard tape is fixed with adhesive compounds or other types of fasteners.

- Laying is carried out continuously, and the joints of tapes from different rolls are necessarily overlapped.

- Particular attention should be paid to the corner zones in the room where the compensation material should be fixed as carefully as possible.

- The installation is completed at the starting point, where the compensation tape should be cut off using a stationery knife with a small overlap.

- The finished version should be neat and carefully fixed, since it is the observance of the basic rules for fastening the compensation tape that directly affects the final quality of the concrete screed.

The fastening of the damper tape is best done with a partner. During operation, one rolls the roll and removes the protective strip from the adhesive layer, and the other holds the clip against the wall.

Video: damping tape installation

What can be replaced

Foams and substrates are also made using foamed polyethylene, but such material will need to be cut into strips, measuring the necessary width and correctly joining. Polyfoam is unable to take its original shape after compression, and cracks form quite naturally. Any wood previously used as damping materials is very short-lived, swells under the influence of moisture and is subject to decay.

In addition, fixing any replacement for adhesives or through fasteners also entails additional costs. Thus, a full replacement of the damper tape, especially if necessary, to complete the arrangement of the “warm floor” system, is absent. Therefore, when pouring a concrete screed, it is impractical to spend time on the use of other materials, and it is very important to competently approach the choice of a high-quality edge strip.

The cost of the finished edging strip is quite affordable for the ordinary consumer, but in the absence of the ability to use high-quality and ready-made compensation tape, it is sometimes possible to replace it in the wall seams with a thick floor substrate, foam or foam, and even traditional wooden battens.

Nevertheless, it is important to remember that such replacement options are, in the opinion of experienced specialists, extremely unreliable and short-lived, adversely affecting the outcome of the concrete screed in any type of room.