How to rub concrete floors: a complete guide

Concrete flooring is a popular solution that is often used in garages, shopping malls, warehouses, utility rooms and living quarters. The final step in creating a high-quality concrete screed is to grout it. This can be done manually, but much faster and more efficiently the work is done using a special trowel, popularly called a helicopter. After pouring concrete, traces of the rule, small pores remain on its surface, and in order to smooth it out qualitatively, grouting is indispensable. In the garage or in the warehouse, after grouting, you can leave everything that way, and in the house, laying a laminate, parquet, tile or other flooring is carried out on a flat concrete surface.

Content

What is a concrete floor grout, is it mandatory to do it

The process of creating a concrete floor consists of several operations, and in order to get a high-quality, strong and durable coating, it is necessary to observe the technology for performing work at each stage.

After the necessary layer of concrete has been applied to the floor and the surface has been leveled using the rule, a stage called grouting begins. To understand the role of this stage of work, we need to figure out what happens to concrete, after its application and leveling.

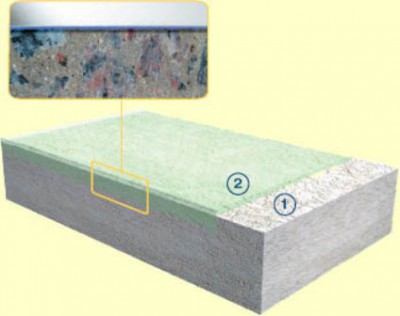

After applying the concrete, large particles of sand and gravel included in it are lowered into the lower layers, while a fine fraction and concrete milk are squeezed up. After moisture has dried, small voids, cracks and irregularities remain on the surface, all this significantly reduces the strength of the screed and worsens its appearance.

We only see external surface imperfections, but in addition to them, microvoids also appear in the upper concrete layers, which leads to a decrease in the adhesion strength of sand and gravel particles to each other, and this causes the upper layer to peel off. As a result of this, significant depressions and potholes appear on the surface soon. Such a floor not only loses its appearance, but also requires repair, and this is an additional cost of time and money.

To avoid the described disadvantages, it is necessary to grout the concrete floor, this can be done manually or using special grouting machines.

How to wipe concrete floors

Depending on the surface area of the concrete floor, it can be grouted manually or with the help of special grouting machines (helicopter). This operation allows you to force an additional seal of the upper layer of the concrete floor, which leads to an improvement in its characteristics. To harden the surface of the concrete screed, grouts are used, which are called toppings.

Regardless of whether grouting will be performed manually or by helicopter to obtain a high-quality surface, this process should consist of the following operations:

- rough grout, it is necessary to seal the top layer and extrude cement milk;

- finish grout;

- coating with a liquid polymer, this allows you to close small pores;

- cutting of temperature joints.

In order to correctly perform all the stages of creating a concrete floor, one must be able to determine the moment of the beginning of each operation. If you do not know how to do this, then it is better to invite specialists.

Manual grout

If the area of the concrete floor is small, then it can be grouted manually. To get the maximum effect from this operation, you need to correctly determine the time when you can begin to carry out work. If you put a board on a concrete screed and step on it, and after that there is no trace left on the floor, it is too late to grout. If the depth of the trace is 2-3 mm, then this means that it is time to begin to grout the surface.

Necessary tools

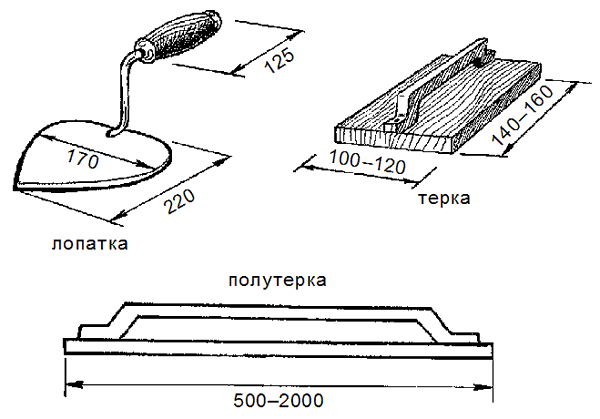

To grout a concrete screed manually, you need a minimum set of tools:

- spatula or trowel;

- grater;

- a half;

- trolley for topping, but you can do it manually;

- knee pads.

What mixtures are used and how to prepare the composition

When the work is done on a small surface, you should not buy ready-made toppings, as they are usually sold in large packaging, and you will not have time to use it up. Most home craftsmen use regular dry cement to grout concrete screeds.

You can use cement with sand in a ratio of 1: 1. The main condition is that the mixture should not have any impurities, the sand is taken in small fractions. After preparing this topping, it is necessary to sift the composition again through a fine sieve, since the presence of large particles will adversely affect the result of grouting the floor and its appearance.

Some home craftsmen like to experiment and add quartz, liquid glass and other components to the composition of the topping. Their proportion is determined empirically. If you want to give the floor higher characteristics, then you need to purchase ready-made toppings. They can be quartz, metallized, corundum and give the surface different characteristics.

Depending on what kind of load is expected on the concrete floor, the amount of topping that must be applied per 1 m will depend2:

- if the load is small and medium, then 5 kg is enough;

- if the load is medium and high, then - 5-8 kg;

- when using color compounds, they must be at least 5 kg.

Work sequence

You can begin to carry out this stage of creating a concrete floor after moisture evaporates from the mixture. Before you begin to overwrite the concrete screed, if there are beacons in it, they must be pulled out and the grooves covered with mortar.

Concrete should be rubbed immediately after water evaporation. To perform the work, polyurethane graters are used, which are tightly pressed to the surface. In order not to damage the screed, you need to use special knee pads, which can be purchased or made independently.

Depending on the ambient temperature and air humidity, it will be possible to start grouting in 6-8 hours. This process consists of the following operations:

- Cooked topping is evenly distributed on the treated surface. On a small area, the prepared mixture can be applied manually, but for a more even distribution, it is better to use a sieve. It is necessary to wait a bit until the applied mixture begins to absorb moisture. The fact that you can start grouting will indicate the darkening of the applied composition.

- Grout.To grout, you need to wear knee pads, so that moving on the surface of the floor, you leave minimal traces. Using a grater, the mixture is evenly rubbed into the concrete screed. It is necessary to rub in a circular motion until the surface acquires a dark gray color.

- Elimination of irregularities. Grouting is done until the floor is even and almost dry. If small traces of tools remain on its surface, they are wiped with sandpaper. To harden the surface, it must be left for at least 4-7 days, but you can walk on it in a day. When the surface finally hardens, it will be possible to fully exploit or proceed with the laying of the finish coating.

It must be remembered that the screed is not grouted on a damp surface, but on a not completely dried concrete floor.

In our next article you will learn about the technology of installing concrete screed: https://floor.expertexpro.com/en/viravniv-stazhka/kak-delaetsya-betonnaya-styazhka-pola.html

Helicopter use

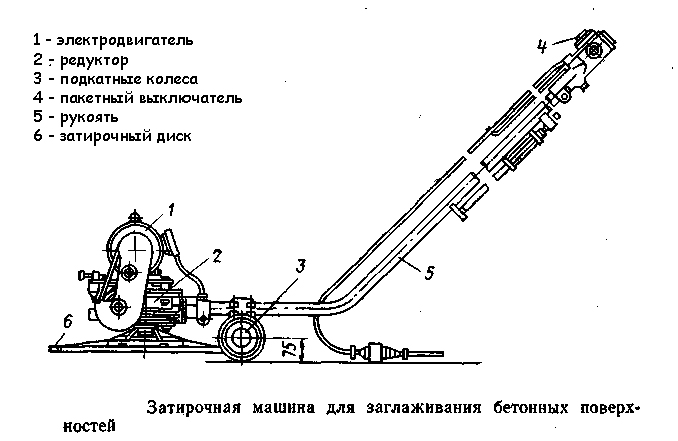

On large areas, concrete floor grouting is carried out using special grouting machines, which are popularly called a helicopter. Such equipment can have both an electric drive and an internal combustion engine. The latest cars are conveniently used in rooms where there is still no access to the mains.

Such equipment can be single-rotor or two-rotor, it has removable disks, which can be made of chipboard or metal. Single-rotor devices are more mobile, their weight is about 30–70 kg, control is carried out using a long handle. Two-rotor models are more powerful and heavy, the operator controls them, being directly on such a helicopter.

Near the walls, in doorways and in sharp corners, wall-mounted devices are used, these are small units having compact dimensions and a limited disk diameter.

Necessary tools

For helicopter grouting, you will need the following tools and equipment:

- rotor blade devices, which, due to the presence of a rotor blade, are popularly called helicopters;

- trolley for topping, it can be manual or automated and is used to uniformly apply the dry mix to the concrete screed;

- wall devices that are used to work near walls, in walkways and sharp corners;

- hand graters, they are necessary to fix small defects, as well as for grouting in hard-to-reach places where it is impossible to do the work using equipment.

What mixtures are used and how to prepare the composition

Since using trowels, work is carried out on large areas, in such cases, they usually do not prepare their own mixes, but buy ready-made toppings. If desired, they can be done independently, the proportions and composition are no different from those used for manual grouting. To obtain a better surface, it is better to use ready-made toppings in which all the necessary components are selected and the correct proportion.

Topping is used topping, which includes the following elements:

- high quality cement;

- dyes;

- plasticizers;

- fillers, their appearance will envy the final properties and appearance of the surface.

For grouting concrete floors, three types of toppings are used:

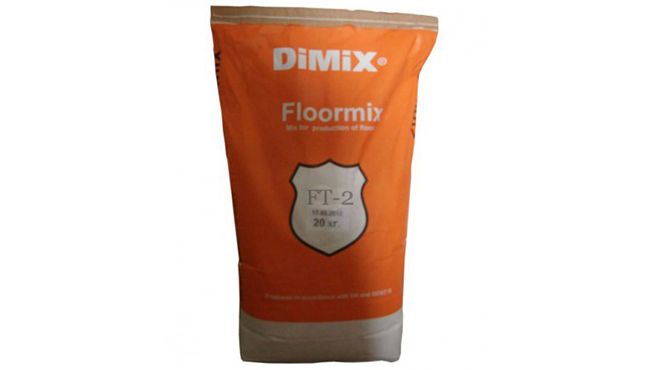

- Quartz. These are the most popular mixtures and their cost is the lowest. Perlite acts as a filler in them, and to give the mixture the necessary shade - coloring pigments.This topping is suitable for rooms with medium floor loads, for example, in a school, store or warehouse. Effectively quartz mixtures are used in residential premises. Thanks to the use of such mixtures, the strength of the concrete coating increases by 1.5 times.

- Corundum. Here, corundum chips with high strength are used as a filler, so that the surface of the concrete screed is hardened by 2 times. Such compositions are used in rooms with intense and heavy loads on the floor. After applying corundum topping, the surface takes on a matte finish.

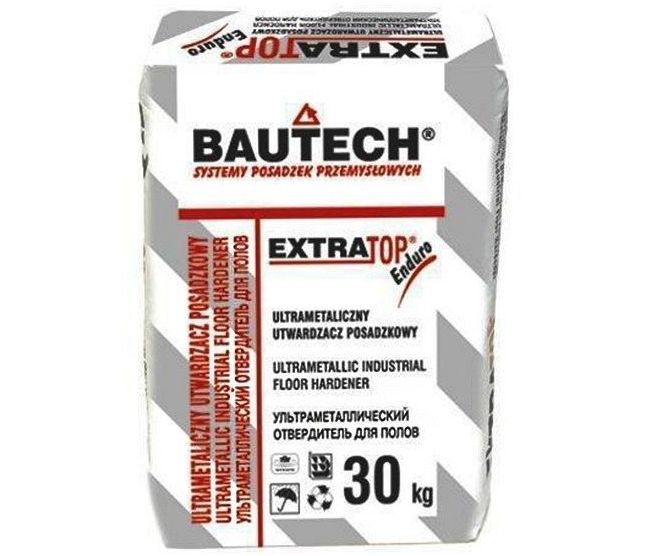

- Metallized. In such mixtures, metal chips mixed with cement are used. This solution allows you to get the most durable surface. The use of metallized topping allows to increase the strength of concrete by 2 times. Such compositions are used in large enterprises, where heavy equipment moves, if there is a lot of vibration. In residential premises, such compositions are usually not used because of their high cost and complexity of application.

How to grout

Grouting concrete screed with a helicopter is carried out in several stages:

- The first application of topping. After you have determined that the time has come when you can carry out the indicated stage of work, proceed to the application of topping. At this stage, about 2/3 of the prepared composition is applied. They do this with the help of a special trolley, which helps to evenly distribute the mixture on the floor surface. To evenly distribute the topping, you can use the equalizer.

- Rough grout. The process is carried out in two passes, while their directions should be perpendicular. During the work, keep in mind that near the columns, walls, the screed will harden faster than in the middle of the room. You need to work quickly to complete everything before the screed is completely dry.

- Second topping application. The remaining 1/3 of the mixture is applied immediately, after roughing the grout, while there is still moisture on the surface so that the topping has time to soak with it.

- Finishing grout. Using trowels, surface treatment is again carried out. Such units have great power, so you need to make sure that their blades do not burrow into the work surface. To get the perfect surface, you need to make several passes, and each time move in the direction perpendicular to the previous one. If you want to get a mirror surface, then gradually the trowel blades must be raised and their rotation speed increased.

Manual way to perform high-quality grout will not work, so if you want to get a flat, smooth and glossy surface, you need to use trowels.

Remember, when applying topping, you can not water the concrete surface with water, so it is very important to correctly determine the time when the floor grout starts.

In order to further protect the concrete surface, polymer impregnations are used. They clog the smallest pores and further bind the particles of the upper layer. This provides a high strength concrete screed and if it is a topcoat, then dust will not form on it. Such formulations are applied with a brush or roller.

At the last stage of work, cutting of the temperature joints is carried out and filling them with sealant.Thus, a durable, reliable and beautiful coating is obtained that will serve for many years.

What mixture to choose for leveling the floor and how to carry out the work, you will learn from our material: https://floor.expertexpro.com/en/viravniv-stazhka/vyravnivanie-pola-samovyravnivayushhejsya-smesyu.html

Video: grouting concrete floors with a helicopter

Concrete floor grouting can be done either manually or using special equipment. Regardless of the method of its implementation, this treatment allows you to increase the strength of the surface, its service life and improve the appearance of the concrete floor. When performing such work, the main thing is to correctly determine the time when you can start grouting. Everything must be done quickly so that the floor does not have time to completely dry. If everything is done correctly, then depending on the topping used, it is possible to increase the strength of concrete by 1.5-2 times.