Choosing a terrace flooring: a comparative overview of the best materials

Terrace - an open area, which is a “transit point” between the house and the street. The choice of flooring for her is not an easy task. The terrace is open for rain, snow, summer heat and winter frosts. Therefore, the material for its coating must maintain its functionality in difficult, almost street conditions. And, of course, have high aesthetic qualities.

Flooring for a terrace should have the following properties:

- High frost resistance. This characteristic is provided by a low rate of water absorption - up to 3%. Materials with such an indicator are not saturated with moisture, it does not freeze in the cold and, accordingly, cannot lead to cracking and damage to the coating.

- Moisture resistant. The terrace floor is exposed to precipitation. Therefore, the materials used for coating should not absorb moisture, deform from it, and rot.

- Durability. Any coating that "works" in atmospheric conditions should have greater strength than home coatings. Otherwise, after 2-3 years it will have to be changed.

- Low abrasion. The durability and appearance of the terrace floor directly depends on this indicator. The minimum abrasion class of materials that are acceptable for terraces is IV.

- Anti-slip properties. They are important for ensuring the safety of people, especially when walking on wet or icy terraces.

- UV resistant. If there is no plan to install a canopy over the terrace, then the sun's rays can reduce the intensity of the coating. This will not happen if you use materials with a high degree of protection against UV rays.

All these characteristics are inherent in the following materials, which are considered the best for covering terraces:

- WPC decking;

- ceramics (clinker, porcelain tile, ceramic tile);

- concrete slabs and tiles;

- stamped concrete;

- stone slabs;

- wooden boards.

Consider in detail all of these options.

Content

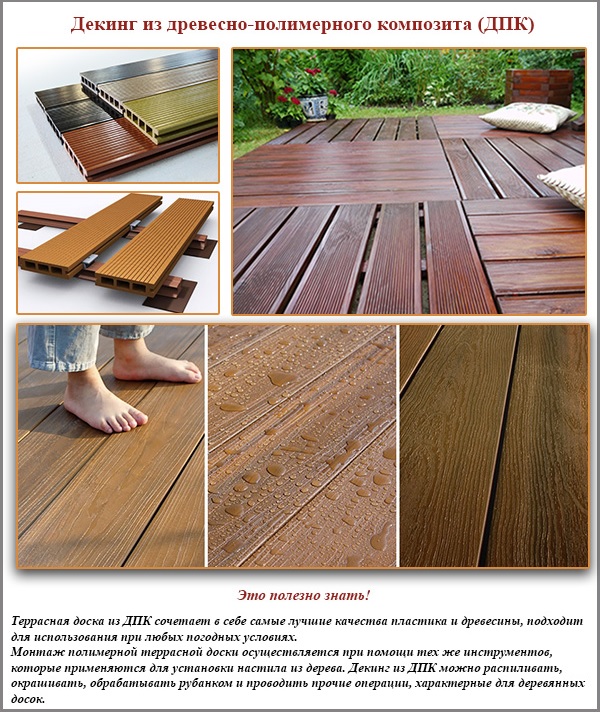

Option 1. Composite decking

A very convenient material for covering terraces is a specialized terrace board. It is made from a wood-polymer composite (WPC), consisting of plastic (20%) and chopped wood (80%). Composite board is a good alternative to natural wood, combining the aesthetics of wood and the smoothness of plastic.

WPC boards look almost natural, but looking after them is much easier. They are easy to wash, they do not require special care. The KDP material is pleasant to the touch, it has no cracks and knots, it does not slip - thanks to the longitudinal grooves.

Decking is a floor covering made up of individual modules designed for outdoor use. Read more about this material and how to install it in the article:https://floor.expertexpro.com/en/pol-pokritiya/parket/deking-vidy-terrasnogo-pokrytiya.html.

Advantages:

- high moisture resistance;

- heat resistance - withstands temperatures from -45 ° C to + 80 ° C;

- the presence of anti-slip grooves on the surface;

- does not need additional processing and coating;

- simple installation (dismantling);

- easy care.

The disadvantage of composite decking is the visual and tactile difference from natural wood, which, despite the efforts of manufacturers, can still be traced.

Option # 2. Ceramics for terraces

The most suitable ceramic products for the terrace floor:

- clinker;

- porcelain tile;

- ceramic tile for exterior work.

Clinker tiles (pavers) are used to finish terraces on the ground or on the screed. In fact, clinker is a burnt brick that has absolute frost resistance and does not absorb moisture at all. It happens with a smooth and corrugated surface, in different colors: from neutral white to rich red. The shape of the clinker tiles is square or rectangular, with straight or chamfered edges.

Porcelain tile is a frost-resistant and reliable tile that combines ceramics and granite. It is distinguished by a variety of design, thanks to the ability to imitate different materials: natural stone (any from granite to marble), wood, leather. Only unpolished porcelain tiles with a rough surface are suitable for terraces. Laying is carried out on a prepared concrete slab, on frost-resistant glue.

Ceramic tiles are also used for terraces. But you need to choose it more carefully than clinker and porcelain tiles. It must be frost-resistant (look for the designation on the packaging!) Specially made for paving on the street. Suitable products with a corrugated, structured surface. Despite the high decorativeness, tiles with a glazed, shiny surface are strictly forbidden to use for terraces. A suitable degree of abrasion is IV or V class.

Advantages of ceramic products:

- high frost resistance;

- durability;

- color fastness under the influence of precipitation and UV rays;

- variety of textures, shapes, colors;

- easy care;

- easy repair (if necessary, you can replace each tile individually).

Disadvantages:

- when paving, it is necessary to observe a slope so that water does not accumulate on the coating;

- moisture can seep into the seams between the tiles, deforming the coating;

- low impact strength;

- porcelain stoneware and ceramic tiles become slippery when icing (this drawback can be circumvented if you use special rubber mats with a non-slip effect).

Ceramic tiles are laid on raised terraces, which are a reinforced concrete slab with a leveling screed. To fix the tiles use special glue for outdoor use.

About how to properly prepare the floor and lay on it porcelain tile, we will tell in the material:https://floor.expertexpro.com/en/pol-pokritiya/plitka/keramogranitnyj-pol.html.

Option # 3. Concrete slabs and tiles

The terrace area can be formed by paving from concrete slabs or tiles on the ground. Laying is carried out on a cement-sand foundation. If the terrace is a raised concrete platform, then the plates on it can be glued using adhesive mixtures for outdoor use. However, laying on a cement-sand mortar is preferable, especially when using large concrete slabs.

With the help of large-sized concrete slabs, you can pave a large platform, having spent quite a bit of time on this. The shape of the plates is rectangular or square. Common sizes: 60x60 cm, 50x50 cm, 60x45 cm, 30x30 cm.

Modern concrete slabs imitate hewn natural stone or ceramics. Especially popular are slabs with an unusual, curly surface. For example, with stamped lines that visually divide the plate into several bricks - for styling ceramic paving stones.

Smaller concrete or paving slabs have a wide variety of designs. They can be of any shape: rectangular, square, diamond-shaped, polygonal, complex wavy.Various embossments are often performed on the surface in the form of lines, cracks (craquelure), compresses (“under the skin”), geometric shapes, colors, etc.

Advantages:

- strength;

- durability (minimum 25-30 years);

- a variety of sizes, shapes, colors and surface structures;

- the ability to create various patterns and ornaments from tiles;

- simple installation;

- ease of dismantling and restoration (for example, if it is necessary to lay communications under the cover, it is enough to remove several tiles, and then put them back in place, without changing to new ones).

Disadvantages:

- when paving, it is necessary to observe the slope for the flow of water;

- in winter, the surface of the tile may be slippery;

- if the base is improperly prepared, uneven subsidence of the tile is observed;

- complexity of choice, since tiles of high and low quality in the store can look the same.

Thanks to the introduction of coloring pigments into the concrete mixture, the color of the tiles can be amazing. Now it is not only gloomy gray tones! In free sale there are tiles of absolutely any color: from white and yellow to rich red and deep blue.

Option # 4. Stamped concrete

This is decorative concrete, the surface of which can copy natural stone slabs, paving stones, wooden parquet, bricks, river pebbles, ceramic tiles. Such a surface can be made on elevated terraces, the base - reinforced concrete slab.

Advantages:

- durability;

- strength;

- the ability to simulate any material;

- a solid concrete surface does not allow moisture to seep under the coating;

- simplicity in leaving.

Disadvantages:

- in the summer heats up very much;

- when using smooth stamps, the surface of concrete can be slippery;

- long installation process.

Stamped concrete - One of the most modern options for decorative coating on the terrace. To create a stamped surface, a layer of special concrete is applied to the terrace slab, on which a “print” is performed using dies made of polyurethane. After stamping, the concrete surface may look like an old pavement or an elite European pavers. Moreover, all the properties of concrete (durability, strength, frost resistance) are fully preserved.

Option # 5. Stone slabs for facing the terrace

Stone tiles are able to harmoniously combine the terrace with the nature of the infield. If the terrace is a raised reinforced concrete slab, then for its lining you can use thin stone tiles, 1-2 cm thick. If you want to design the terrace on the ground, large slabs 3-6 cm thick are suitable. In this case, crushed stone or sand will be the basis pillow.

Advantages:

- high esthetics;

- durability;

- when abrasion does not change the appearance, beautifully aging.

Disadvantages:

- the stone is very hot in the sun;

- upon impact, cracks may appear on the surface;

- seams are easily contaminated.

When choosing stone tiles for terraces, pay attention to moisture resistance and the degree of abrasion of the rock. The most stable in open areas are slabs made of granite, basalt, slates, syenite. On the covered terraces you can use sandstone, travertine, limestone.

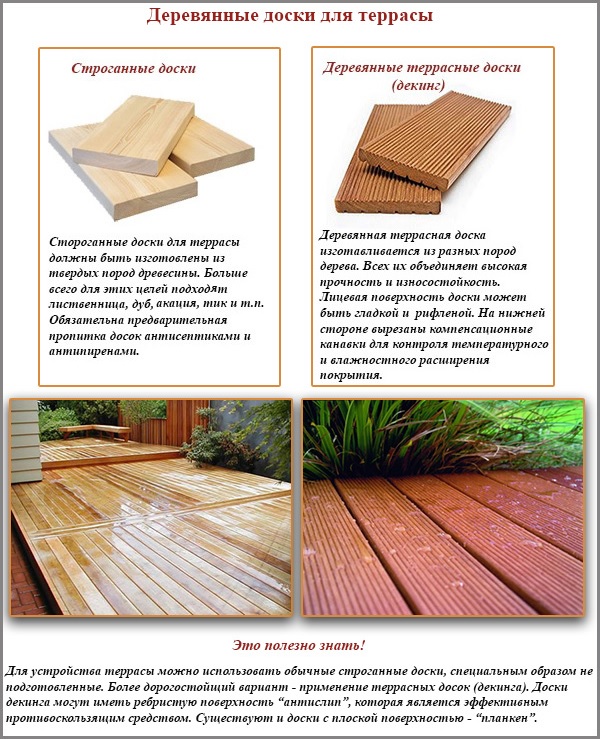

Option # 6. Wooden boards

Wood is a traditional material for a terrace. Wooden boards create a durable, beautiful and warm to the touch coating. As a rule, he is satisfied with laying boards and wide slats on the frame of lags and girders. It is possible to lay antiseptic thick boards on the crushed stone base.

For outdoor terraces, it is recommended to use boards made of moisture-resistant hardwood: larch, teak, oak, merbau, kumaru, iroko. They have a high density, therefore they are not subject to decay, resistant to insects, and retain their original appearance for a long time. Similar properties can be given to the material artificially, by heat treatment.In the process of heating to combustion temperatures, the wood ceases to absorb moisture, therefore it does not decay, does not crack, does not deform. Heat treatment technology is used for spruce, pine, ash, beech, birch.

You can read about different types of terrace boards and how to stack them in a special article on our website:https://floor.expertexpro.com/en/pol-pokritiya/terrasnaya-doska-iz-dpk.html.

Advantages of a wooden surface:

- warm surface;

- depreciation properties;

- high decorativeness;

- environmental friendliness;

- a wide range of colors, sizes, structures of boards.

Disadvantages:

- changes color under the influence of UV rays;

- difficulty in leaving;

- regularly requires treatment with antifungal coatings.

In the manufacture of terraces, planed boards (treated with antiseptics and flame retardants) or special terrace (deck) are used. The last option is the best. Terraced wooden boards (decking) are made only from hard wood (otherwise, heat treatment is used). Their edges are rounded, and a spike-groove mount is not provided. Decking elements are placed at a small distance from each other, so that atmospheric moisture flows freely through the gaps. The surface of the boards can be not only smooth, but also corrugated (with grooves) - this increases the anti-slip properties of wood.

When choosing materials for flooring a terrace, it is not necessary to dwell on one option. If you liked several paving methods, why not combine them? For example, combinations of tiles and wood, stone and clinker, clinker and decking are very popular.

4 comments