Types of terrace boards and methods for its installation

The dream of many owners of private households is a beautiful, spacious gazebo or outdoor terrace. Terrace board made of natural materials looks especially impressive in the decoration of these structures. Such objects harmoniously fit into the surrounding landscape of the site. Modern technologies make it possible to process natural wood in such a way that it does not lose its properties, after spending many years on the street in the form of an arbor or porch decoration.

Content

What is a terrace board

This covering is especially popular among facing materials for the street. The board is made from solid wood, wood-polymer composite or WPC. For raw materials, cellulose fibers, wood of various species crushed into flour, sawn timber are used, they make up 50-60%. The remaining 40–50% are polymer compounds and chemical additives that add strength to the board and improve its performance.

Board for street decoration has the following technical characteristics:

- high moisture resistance, water absorption coefficient of not more than 4–5%;

- increase in density of the board structure after processing up to 1.2 g per cm²;

- preservation of working properties at -40ºС in the winter and at + 75ºС in the summer;

- combustibility class - G4, does not burn even when exposed to an open flame;

- coefficient of abrasion 0.1 g per cm²;

- withstanding significant loads - 400-500 kg / m²;

- declared minimum service life of 15 years;

- immunity to precipitation, ultraviolet, biological damage: mold, fungus, rot;

- resistance to heat and dryness.

Thanks to such qualities, the terrace board is used in the decoration of piers, outdoor areas by the pools and in water parks, arbors and porches, terraces and verandas. A good solution is the lining of balconies and baths with this material, laying out of garden paths. The board is used by designers in the decoration of restaurants, dance floors, outdoor cafes. In the bathroom, the finish from the board looks interesting and enlivens the interior.

Varieties of terrace boards

Manufacturing companies produce a wide range of facing strips for the street. They can be divided into several main groups according to the composition and processing technology.

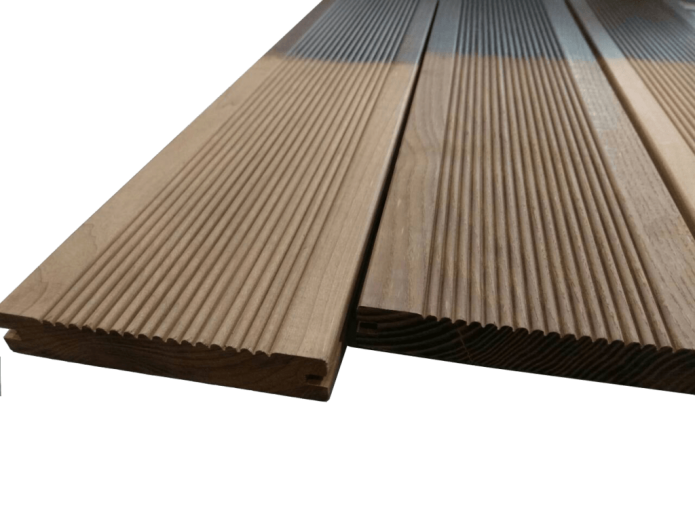

Natural wood

This is a board impregnated with special compounds and machined mechanically, with cuts or corrugations, coated with protective layers that improve the characteristics of the array. Special grooves are cut along the edges for the lock connection of the slats. It is made from exotic and valuable species of trees, such as bamboo, oak, teak, sequoia, azobe. These textures are distinguished by the beauty of natural patterns and environmental cleanliness. Such a board is used in rooms where the naturalness of the material is important, for example, in baths, on balconies, in bathrooms.

Standard board sizes:

- length varies from 1.5 to 6 meters;

- width is from 140 to 160 mm;

- thickness is from 24 to 38 mm.

Heat treated array

The material goes through numerous stages of thermal exposure, due to which its structure and chemical properties change, the board acquires greater strength and a more decorative appearance. The density of the lamellas increases several times. The fibers and the overall shade of the wood become bright and distinct. The service life of thermally enhanced finishes is extended to 25 years.

Advantages of thermal mass:

- low thermal conductivity, boards remain cool even under the scorching sun;

- non-slip surface;

- it is pleasant and safe to move around without shoes;

- ecological cleanliness and fire safety.

Of the shortcomings, only the high cost due to the naturalness of the material and the complexity of the processing technology can be noted.

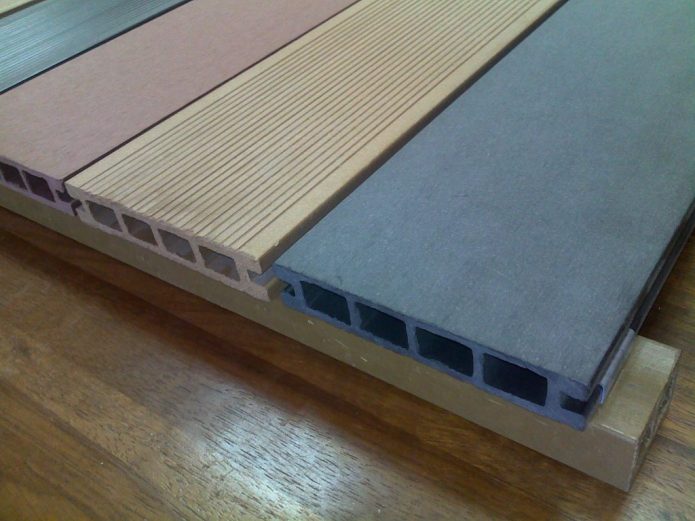

Decking from wood-polymer composite (WPC)

It is an artificial material made from wood, polymers and cellulose. Outwardly, it looks like a natural board with corrugations and locks on the sides. The optimal ratio of the composition of sawdust to other components is 80 to 20%. Such lamellas are pleasant to the touch and have a uniform structure.

Manufacturers paint their products in various shades and imitate any kind of wood, which allows to realize the wildest fantasies of designers and ideally fit the terrace into a common ensemble.

Decking Benefits:

- ease of installation;

- high strength and wear resistance;

- light weight, ease of transportation;

- weather resistance;

- low cost;

- service life up to 50 years;

- the possibility of laying a system of underfloor heating;

- immunity to detergents, aggressive substances.

When choosing a WPC, the load class should be taken into account. Standard is used in private homes, professional - in places of commercial use: restaurants, hotels. Expert class material withstands extreme loads and is suitable for decoration in shopping centers, water parks and off-road areas.

DIY decking

Having carefully studied the installation technology and prepared all the necessary tools and materials for work, you can carry out the installation of street decoration on your own, without the involvement of third-party specialists.

General recommendations

Even if the platform for cladding has a simple shape, it is recommended to draw a drawing and layout the layout in order to correctly calculate the amount of material to buy.

Calculation of the number of planks for laying

First, you should calculate the area of the terrace by multiplying the length by the width, for example, the area of the plot with a length of 5 m and a width of 4 m will be 20 m². The number of boards depends on the type of material laying:

- The direct method, when the boards are mounted parallel to each other, does not require trimming of corners and additional expense.

- Diagonal laying visually expands the space and requires trimming of the material for laying at an angle. For the diagonal method, the flow rate should be increased by 20%.

- Herringbone installation will require an addition to trim in the amount of 20%.

In addition to slats, you will need accessories and fasteners: logs, profiles, clips, angles, screws, plugs.

Installation

When installing terrace slats, a number of rules should be followed that will help to avoid mistakes during construction work:

- logs and dressing boards should be made of identical material. Wood and composite have different expansion ratios. A strong connection in this case will not work;

- for a natural discharge of water you need to make a slight slope of the coating.A slope of 1 cm for each linear meter of the site is enough;

- Gaps must be left between the floorboards and walls for the thermal expansion of the material, otherwise the boards will begin to deform;

- It is necessary to strictly observe the distance between the lags, which is indicated in the instructions for all types of boards, otherwise there will be a risk of failure or deflection of the slats;

- ventilation is necessary for terrace coverings, therefore empty spaces should remain in the logs under the boards;

- works are carried out in dry weather at a temperature from + 5ºС to + 30ºС; Humidity is desirable no more than 40-60%.

Concrete laying

A reliable and solid foundation for the construction of a gazebo or porch is a reinforced concrete slab or concrete screed.

For installation you will need the following tools and materials:

- tape measure, laser or water level, marking pencil;

- drill, screwdriver, screwdriver;

- jigsaw for sawing corners and dividing strips into parts;

- a mallet to fit lamellas and align gaps;

- fastening materials: clamps or staples with hardware, preferably from the same manufacturer as the board;

- linings, caps, accessories for flooring.

Surface preparation

- To clear the basis of dirt, dust, spots of oil and glue, bitumen and soot.

- The surface of the screed should be dry and clean, the concrete grade is frost-resistant.

- Check the level of slope to drain moisture.

- It is recommended to cut special drainage grooves with a depth of about 15 mm and a width of up to 30 mm.

- Impregnate the wooden elements of the frame with protective compounds to prevent decay, fungus, mold or moss growth. Impregnation is recommended fire-retardant and indelible.

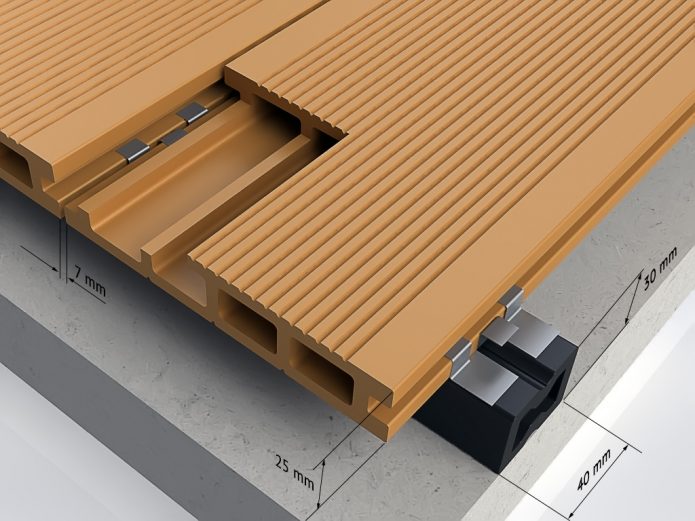

- Now you can mount a single-tier frame from the log with a step of 30-50 cm and a gap for thermal expansion to the walls of at least 8 mm. Aluminum profiles, WPC or wood are used, depending on the finishing material. Between dissimilar elements rubber strips are laid. Logs should be laid out on the surface, check the distance between them, drill holes in the beams at a distance of 50-100 cm and fix them together with corners or hardware.

Installation of a terrace board

- It is better to bring a set of slats to the construction site in advance, they should be unpacked immediately before installation. Work begins from a far corner, edge, wall or column. On the frame log using self-tapping screws, fasten the starting clips, corners, guides. Put the first board, a little hit with a mallet, aligning the position of the lamella and fix it on the other side with a bracket or a clammer. Then put the next board and, similarly, knock and fix.

- Installation of all boards with direct laying is carried out in one direction in order to avoid the so-called striping. The flooring canvas can protrude beyond the frame by no more than 5 cm.

- Lay out the entire flooring, after installing the last strip, attach the finish profile, corner, guide to it.

- The ends of the hollow planks of the KDP close decorative caps.

- After the installation is completed, the finished flooring surface must be washed with mild detergents.

Ground laying and logging

For laying the terrace board not on a reinforced concrete slab or screed, but directly on the ground, additional preparatory work, tools and materials will be required.

- geotextiles to strengthen the soil and against weed germination;

- drainage pipes;

- sand, gravel, gravel to create a pillow under the frame;

- concrete elements of a point support, they can be from other materials;

- shovel, rake.

Preparation of the foundation for laying on the ground

- Remove topcoat of unstable soil, grass and soil.

- Cover the area with crushed stone or mineral concrete and compact with a vibrating method.

- Mount the drainage system by laying perforated pipes.

- To lay geotextiles, which will prevent the germination of weeds and mixing of various types of bulk soils. This layer strengthens and stabilizes the pillow and protects the entire structure from subsidence during operation.

- Create a cushion of gravel and sand 5 cm thick.

- It is advisable to place point supports made of concrete. It is possible to mount the frame on pre-paved paving slabs, asphalt, and another smooth base.

Creating a frame and installation of terrace decoration

- Position the beams at a given distance, fasten to the grate with screws. If the surface of the base is not completely smooth, adjustable pads are installed under the logs.

- The board can be fixed closed and open. The simplest one is with self-tapping screws that are screwed into the entire thickness of the slats plus the thickness of the lags. The gap between the lamellas is 5-7 mm. Hats fasteners are recessed into the surface of the material so as not to scratch and injure when walking. With the closed method using clips, the flooring looks more aesthetically pleasing as a single canvas.

- The ends of the boards are evenly filed and covered with end strips, remove debris, dust, dirt.

- On top of the finished clean surface, you can apply additional protective waxes, oils.

Care Rules

It’s easy to look after a flooring from an array or KDP, here are the basic rules for prevention:

- to clear snow and ice, you need to sprinkle the coating with salt, and then rinse with water;

- rust can be removed with oxalic or phosphoric acid;

- dirt is washed off with detergents and a hard, but not a metal brush;

- oily stains should be removed immediately with hot water and a degreasing agent;

- stains from berries, wine and red juices are washed with hot water with bleach;

- ink stains can be removed with hot soapy water;

- the use of sand, abrasive detergents, metal brushes and scrapers is contraindicated. They can scratch the surface and damage the protective layers of the lamellas;

- within a few months after installation, the composite coatings become slightly lighter;

- dry cleaning, cleaning of leaves and garbage is done with a brush.

Owner reviews

They made larch floor on a cold balcony, everyone likes it ... Larch is covered with 4-5 layers of American water-soluble yacht varnish (the choice fell on him, because the result is beautiful, and there is absolutely no smell)

I have two terraces in different areas. On one lies a composite wood polymer for the second year, and on the other a larch for the sixth year. KDP is easier, wash it from Körcher under pressure. Only in the first season did we stabilize the board with osmosis. Larch is good, but a terrace of 29 square meters eats about 12-15 thousand rubles. annually. We fake, paint, cover something.

Decking is an excellent option for a terrace, such polymer boards, as they are also called, are not afraid of moisture. So don’t worry. Decking is also not susceptible to temperature differences, because the material is partly plastic.

Larch has been lying for a year. The impressions are positive - the warmth of the tree is especially pleasing when you walk barefoot. Treate with bio protection and then oil. I recall that I also saw somewhere polymer things: but they are still “dead”, so the tree outweighed me.

It is best to use a board for an open terrace from cypress, it will last a very long time. Cost, of course, it will be very expensive. If funds do not allow, then lay the tile.

Clean and well-groomed outdoor decking will last for many years. The board looks neat and natural, it is pleasant to walk on it barefoot. Laying from decking decorates the area near the house and does not require special care.