We select and prepare boards for laying the wooden floor

The choice of materials for the device and flooring is quite wide. But only a plank floor combines both bearing and decorative qualities. The only exception is the engineering floor board, which is a kind of parquet. Not only the aesthetics of the future coating, but also the service life depends on how correctly the boards were chosen, how they were prepared for laying, and on compliance with the technology of the flooring.

Optimal quality board parameters

Choosing floor boards is necessary based on several parameters. First of all, this is the design of the board itself. There are grooved and ordinary boards. A distinctive feature of the former are castle joints at the ends. That is, in the right side you will see a groove, and in the left end a thorn of the same size. When laying the boards, the spike is inserted into the groove, which guarantees a reliable connection and prevents the appearance of cracks.

An ordinary or technical floor board has straight ends and fits end-to-end. Of course, the cost of a grooved board is slightly higher. But a good wooden floor with proper installation and exploitation can last you a lifetime. So is it worth saving? You probably saw a strong wooden floor, the appearance of which far from perfect: the center of the board sagged the edges rose and cracks appeared between the boards. This can only happen with a non-grooved board. The conclusion suggests itself, such material can only be used as a rough floor.

Important! An exception to this rule is only oak flooring. Due to the hardness of wood, such boards do not “lead” over time, and non-grooved material can be safely used.

Wood species - the foundation

So we came close to choosing a species of wood for your floor. Let's look at the most common ones:

- Oak - It is certainly expensive, but very beautiful and practical. Spending on such a board, you can be sure that you do not have to change the gender, and with proper care it will serve your grandchildren as well. So, when deciding which boards are needed for the floor in your home, think about whether you want to change them in a couple of decades or are you ready to pay once for the quality.

- Siberian Larch - also quite expensive wood. On average, its cost exceeds the price of pine by 2-3 times. However, due to its special hardness and high resin content, the larch floor practically does not decay and does not wear out. It is great for wet rooms or for houses where the owners do not live all year.

- Alder and aspen - do not differ in special durability, but possess a number of other advantages. First of all, the enzymes secreted by these tree species have a great effect on human health, especially on the children's body. So most often laying floor boards of these breeds is produced in children's rooms and bedrooms, where the load on the coating is not large, and the healing ability can manifest itself most fully.

- The most common floorboards made of coniferous wood - fir, spruce, pine. For residential premises where it is not customary to walk in street shoes, such a floor is quite suitable. We can say that this is the most budget option. Having opted for pine lumber, prefer a grooved board. Only in this case can you expect that in a few years your floor will not go “waves".

Choosing your favorite breed of wood for the floor, do not forget about protection against parasites and mold, as well as fire.What are the protective impregnations, and how to choose them? Learn about this in the material:https://floor.expertexpro.com/en/ustroistvo-rmnt/antiseptiki-i-antipireny.html.

Wood moisture

The wood must be well dried. Otherwise, having made the floor from the boards with your own hands, in just a couple of weeks you may be surprised to find that some of its fragments were twisted with a “screw”, so much so that the screws were pulled out of the floor. Naturally, such a floor will have to be redone, and this is an additional cost of time, effort and money. The optimum humidity of the floorboard is 8-10%, maximum is 12%.

Board thickness

The thickness of the floorboard also depends on the selected wood species. So, you can use oak boards with a thickness of 20 mm. For pine, the ideal thickness is 40 mm. The tongue and groove board is produced according to slightly different standards. Its thickness ranges from 28 to 36 mm. When choosing, you need to proceed from how much a floor load is planned: the greater the load, the thicker the board is needed.

Board width

Few people know that the durability of a wooden floor depends in many respects on the width of the board. This is especially true for non-grooved material. The width, in turn, is selected depending on the moisture content of the wood: the higher the humidity, the more you need to take the board. The optimal width is 100 mm, but if you are sure that the tree is properly dried, you can use a board with a width of 180-200 mm.

The mounted wooden floor must be prepared for applying paintwork or other coatings. The first stage of preparatory work is always grinding the surface. Here's how to do the work yourself:https://floor.expertexpro.com/en/ustroistvo-rmnt/shlifovka-derevyannogo-pola.html.

Acclimatization Stage

Before you make the floor of the boards, you need to let the material get used to the temperature and humidity of the room. To do this, just fold it in the room and leave it for several days.

Important! In order to save, sometimes the floor is installed from boards of high humidity - up to 20%. In this case, it is recommended to stack them immediately after delivery, without acclimatization. However, this option is very risky. It is difficult to predict how the board will behave during drying.

What should be the basis?

Base for plank flooring can be almost anything. The main thing is that it be strong enough and withstand the additional load. It can be:

- concrete floors;

- lags;

- floor beams;

- old wooden floor;

- screed plywood base.

Methods of fixing boards on the base

The method of mounting boards depends on their type. So, a non-grooved board is attached to the logs with nails or self-tapping screws at an angle of 90 degrees to the base.

You can add noble shades to wooden with a stain. Read about the features of this type of coating and the application technology in the article:https://floor.expertexpro.com/en/ustroistvo-rmnt/morilka-svoimi-rukami.html.

The tongue-and-groove board can also be fastened, or it can be laid down, hiding the screws. The algorithm of actions is as follows:

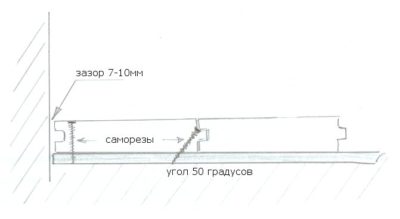

- We fix the first board through the front surface at a distance of 7-10 mm from the wall with a groove to it.

- In the next board from the side of the spike we drill a hole at an angle of 45-50 degrees.

- We install the second board so that the spike and groove coincide, leaving no gap between the boards. To do this, you can gently hit the end of the board several times with a hammer through a wooden block.

- When the board has taken its place, we fasten it with screws through the prepared hole.

- The last board is also fastened through the front surface.

Important! If the width of the board is more than 140 mm, it is advisable to additionally fix it in the middle, by inserting the self-tapping screw head into the array and closing the hole with a screw.

That's all. Paul is ready.It remains only to apply a protective coating and you can use a beautiful, durable and environmentally friendly floor for many years.

2 comments