Wood floor stains: a review of the compositions for tinting parquet and solid wood

Mahogany or oak parquet is not affordable for everyone. But this is not a reason to deny yourself the contemplation of noble shades. It doesn’t matter what your parquet is made of - tinting will help it “repaint” into the most expensive wood species. For this, there are special tinting compounds - stains, with which the wood can be given any color. As a rule, this is the color of a more expensive, elite breed. What tinting liquids are called stains? What are their characteristics and how are they applied to a wooden surface? Read about all this below.

Content

What is stain and why is it needed?

Stain is a tinting liquid that is used to give wood an unusual tone. Penetrating into the structure of wood, stain dyes it without forming a film on the surface. In other words, the texture of the tree remains visible, only its color changes. Due to this, the pine floor can be given a visual resemblance to walnut or oak flooring. Naturally, this similarity will only be external! Other characteristics of the breed (resistance to decay, hardness, strength) will remain unchanged.

Types of stains: we select the necessary composition

Modern stain-impregnation can be completely different in composition. Depending on the "content", they are divided into:

- water;

- alcohol;

- oil;

- nitromethyl.

Let's dwell in more detail on each option.

1. Water stains - the most common, allow you to color the wood in any tone: from the lightest "pine" shade to dark mahogany. Such stains are sold in two forms: in liquid and dry state. Liquid water stains are ready to use immediately, and dry powders require preliminary dilution with warm water.

Water stains are practically odorless and this is a huge plus, if necessary, stained wood in the premises. But they dry for a long time - about 12-14 hours. In addition, water stains have the ability to raise the pile of wood during the staining process, which leads to the need for its subsequent grinding.

Among the water stains, a separate group distinguishes acrylic stains made on the basis of acrylic resins. They are resistant to fading and are not washed out by water, less raise wood fibers. Their disadvantage is the high price.

2. Alcohol stains are solutions of various aniline dyes in alcohol (denatured alcohol). After applying the stain, the coloring pigments quickly penetrate the wood texture, and the alcohol disappears. Complete drying of the alcohol stain occurs in 15-30 minutes. Therefore, it must be applied quickly to avoid spots and erosion. Even staining with an alcohol stain is obtained by spraying it from a spray gun.

3. Nitromorilki - solvent based stains. In their specificity, they are similar to alcohol stains. They require quick application, preferably with spray guns.

4. Oil stains - solutions of dyes in oil (most often flaxseed). They are evenly and easily applied, do not pick up fibers.The coloring pigments of oil stains are highly lightfast, therefore the surfaces painted by them do not change their brightness for many years and retain their original appearance.

When applying oil stains, you can use a spray gun, a wide brush, rags. Drying of oil stains usually lasts 2-4 hours.

Which color to choose?

Each stain color according to international classification has its own code. And the name corresponding to the species of wood, the color of which imitates a stain. For example, stain "Mahogany", "Oak" or "Plum". But choosing impregnation only by name or picture on the label is unreasonable. You can get unpredictable results. There are reasons for this:

- The colors of the stains of the same cipher, but from different manufacturers, can vary significantly in shades. For example, the water stain “Larch” produced by the Tsaritsyno paints has a pinkish-brown color, and the same “Larch” from “Novbytkhim” differs in a soft yellow hue. Many stores display dice samples painted with different stains. Samples will more accurately convey the true color of the stain than the picture on the label.

- The type of painted wood is significantly affected by its characteristics - natural color, density, structure. For example, a stain on a mahogany will look darker than on a maple (provided that a stain of the same tone is used). This is due to the fact that mahogany wood itself is a darker shade.

The same experiment with maple and pine samples will show that pine wood stains more intensively and faster. Pine is softer and more porous, and maple is dense and hard. Therefore, coloring pigments are easier to penetrate into pine wood.

The degree of staining also depends on the texture of the wood. Oak with a pronounced texture quickly darkens from the stain due to the fact that the coloring pigments penetrate the deepening of the veins. The main part of oak wood (outside the veins) is painted less quickly and intensively.

What is the best way to apply a stain?

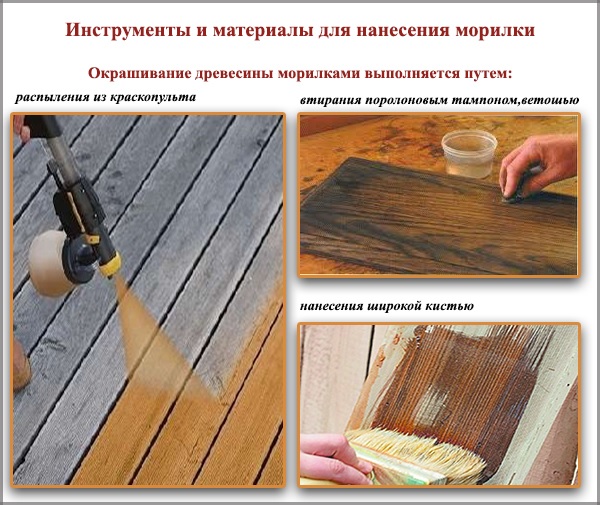

For applying stains, you can use: spray gun (with nozzle size not more than 1.5 mm), a wide brush (100 mm wide), a foam rubber swab, rags. If you have to process a large area, then definitely you should prefer a spray gun. It is also used when using nitromorilok and alcohol stain. They dry too quickly, so when they are applied with brushes or tampons, stains often form on a wooden surface.

Water and oil stains are well applied with brushes, tampons and rags. Brushes with natural bristles are more suitable for oil stains, with synthetic bristles for water-soluble ones. The bristles should be strong, not leaving hairs on the surface.

Fabrics and tampons used for stains, you can use cotton, foam. They also should not “strew” with pile and thread, which can remain on an already painted surface and reduce the quality of the coating.

The preparatory phase: the manufacture of color samples

After buying a stain, but before the start of direct staining, it is advisable to make a color test (test color). It is necessary to understand whether this stain is suitable for a particular surface, to reveal the final color and determine the number of necessary color layers.

For the manufacture of a color sample, a board is used that has been treated (sanded, sanded) in the same way as a wooden surface to be painted. Naturally, the wood species of the sample board should also coincide with the main surface.

The board is covered with stain in one layer. After drying, a second layer is applied to 2/3 of the sample. The third layer stains another 1/3. The dried stain is covered with two layers of varnish. Comparing the staining intensity of each part of the sample, choose the number of layers that is most suitable for a particular surface.

To choose the best option, they often make several test colors. To do this, several planks are covered with different stains. Then make a choice.

Surface treatment before work

Before applying the stain, a wooden coating must be prepared. Do it in stages:

1. Remove the old coating (if any). To do this, looping and grinding boards. In addition to removing old coatings, these procedures will even out the floor.

2. They cleanse the surface of grease and oil stains by wiping problem areas with a rag dipped in white spirit or gasoline.

3. Conifers, before applying the stain, it is advisable to tar. That is, to remove resin from the wood structure, which may interfere with the absorption of the stain. Solutions for demineralization are prepared according to the following "recipes":

- 50 g of potassium carbonate and 60 g of soda ash are dissolved in 1 liter of water heated to 60 ° C.

- 50 g of caustic soda are dissolved in 1 liter of warm water (soft). The resulting 5% soda solution is treated on the surface.

- 750 ml of distilled water are mixed with 250 g of acetone.

Any of these solutions is copiously applied to the boards, preferably in several layers. After half an hour, wipe the surface with a cotton cloth and rinse with warm water.

Step-by-step staining technology

Despite the many preparatory steps, the direct process of applying the stain is completely uncomplicated. Perform it as follows:

1. The wood stain is slightly heated to increase the degree of penetration into the wood.

2. A swab, rag or brush moistened in a stain. Strong moistening cannot be allowed, otherwise the appearance of sagging and uneven coloring. When using a spray gun - pour stain into the tank.

3. Apply a stain along the wood fibers. They try to work quickly, without interruptions, to avoid stains. When sagging, wipe the surface with a soft cloth, "pulling" excess fluid along the fibers. Leave the stain to dry completely.

4. In a similar manner, several more layers are applied to obtain the desired shade (usually 2-3 layers).

5. Finally, the surface stained with stain is varnished in several layers with the sanding of each intermediate layer with fine-grained sanding paper.

Massive Whiteboard Video Example

To understand the technology of staining with stains, it is enough to see this process once. We suggest you familiarize yourself with the video, which presents a method for painting a massive board by rubbing stains.

5 comments