Thermal insulation of concrete and wooden floors: a comparative review of insulation methods

Comfort in any room depends largely on the ambient temperature. Moreover, the fundamental factor is the temperature above the floor surface. The preservation of heat in the house includes several components. One of which is the thermal insulation of the floor. Heat losses due to poor insulation not only reduce the level of comfort, but also increase the waste of heating rooms. Therefore, it does not matter which floor in the apartment or house: concrete or wood - it must be insulated.

Before arranging thermal insulation of the floor, it is necessary to choose the right insulation. The main criteria for thermal insulation materials:

- light weight;

- poor thermal conductivity;

- moisture resistance;

- durability.

The insulation is selected depending on the floor device, the type of flooring and the purpose of the room. The most popular thermal insulation materials:

- mineral wool;

- Styrofoam;

- polyurethane foam;

- polystyrene foam;

- expanded clay;

- perlite.

Content

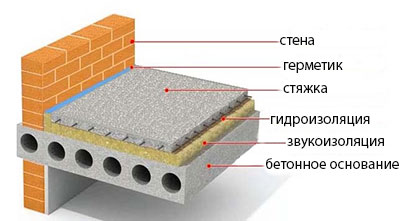

Concrete base insulation options

Depending on the device, the concrete floor is insulated with lags or concrete. In the first case, you can use bulk insulation or mineral wool. Due to the fact that the logs take on the bulk of the floor, the load on the material will be negligible.

When insulating the floor on a concrete base, the main load will go to the heat-insulating layer. In this case, it is better to use polystyrene foam extruded or mineral plates.

Thermal insulation of the floor on the logs

Insulation of the lags is done, as a rule, during the construction process. With this method, the height of the room is reduced by the height of the floor (7-10 cm). The concrete base must be dry before laying the insulation. A layer of waterproofing material or plastic film is laid on it.

Next, lags are installed in increments of 50-60 cm. Heat-insulating material is laid in the space between the lags. The thickness of the insulating material should be a couple of centimeters less than the height of the lag. This is necessary for the circulation of air under the floor. The next stage is the arrangement of the raised floor (when laying, indentation from each wall is 1.5 cm). Particleboard or waterproof plywood will do for this purpose. At the end, the floor is laid.

Chipboard

Before laying the insulation layer, the dry concrete floor is covered with waterproofing material. They begin laying the plates, stepping back from the wall 1.5 cm. If this is not done, then under the influence of heat and moisture, the plate will expand and deform.

The insulation material is fastened with dowels. When all the boards have been laid, the docking slots are glued over with a construction net. Then they are covered with putty with diluted oil paint. A floor covering is laid on top of the insulating layer.

Thermal insulation by the method of "floating floors"

The method of "floating floors" got its name because of the lack of connection of the floor with a concrete screed. An insulating substrate is laid first.To do this, you can use glassine. It is necessary to overlay it with an overlap of one strip on another with an overlap width of 10 cm. At the joints of the floor with the wall, the glassine should go slightly onto the wall. The next layer of insulation is made of mineral fiber, polystyrene or extruded polystyrene foam.

Laying of insulating material is made close to each other. There should not be the slightest gap between the material. Therefore, it is better to lay two thin layers in opposite directions than one thick layer. With the help of guide rails, the entire structure is poured with concrete mixture. After the concrete has hardened, the guides are removed, and the grooves remaining after them are poured with mortar.

When pouring a "floating floor" it is necessary to control that concrete does not fall on the walls and screed. Otherwise, the floor will no longer be “floating”.

After the floor has completely dried, it is checked for defects, which are immediately eliminated. Any floor covering is laid on top.

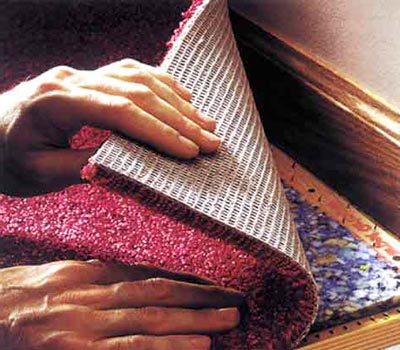

Carpet or linoleum flooring on insulation

Before laying carpet or linoleum on insulation, it is necessary to prepare the base. Level concrete screed. It is advisable to lay polyurethane foam on top. Carpet or linoleum can be glued to the base using a bustilate or fixed with skirting boards. The joints of the flooring are glued. To make it warmer under the carpet, you can put an additional layer of felt insulation.

Isolon insulation

Isolon has a lot of advantages necessary for a heat-insulating material. In addition to its insulating characteristics, it is lightweight, flexible and resilient. It has almost zero water absorption and high resistance to decay. This method is good for those for whom thermal insulation of the floor with their own hands seems an impossible task. The method of laying it is quite simple. Having rolled out the isolon on the floor, it is glued to the base with tape. On sale there is a self-adhesive isolon coated on one side with glue.

Work with technical traffic jam

Despite the fact that the thickness of the technical cork does not exceed 1 cm, it is able to retain heat for a long time. The small thickness of the product allows you to insulate the floors even in two layers, without hiding the height of the room. The method of laying the technical cork is the same as the isolon. The advantages of this material can also be attributed to its environmental friendliness, the disadvantages are its high cost.

The nuances of floor insulation in a wooden house

Increasingly popular are houses from a log house or timber. To finish such buildings, they try to select environmentally friendly materials. It is important to maintain the perfect aura of natural ingredients. Therefore, the thermal insulation of the floor in a wooden house should be made of environmentally friendly materials. The presence in the composition of heaters phenol, ethanol and other unnatural components should be scanty or completely absent.

According to these indicators, mineral wool or fiberglass can serve as insulation for the floor. Choose a material of light shades. A brown shade of mineral wool indicates the presence of phenol-formaldehyde resins. The presence of the same additive in fiberglass gives the material a yellow tint. In any case, when choosing a material for thermal insulation of the floor, it is advisable to familiarize yourself with its composition.

In wooden houses, floors are also spread on wooden floors. The thermal insulation of such floors is similar to the insulation of concrete floors along logs, but has its own nuances. Insulating material is laid over the subfloor. In this case, between the insulation and the floor, both draft and finish, it is necessary to leave air space. The distance from the subfloor to the insulation is 1-2 cm, and from the finishing to the insulation - 10-15 cm.

Such air layers not only improve the thermal insulation of the floor, but also ensure the removal of excess moisture. And moisture, as you know, promotes decay. The only drawback of this design is the possibility of settlement of rodents in the air gap. To prevent this, an obstacle in the form of a fine-mesh metal mesh is made under the rough floor.

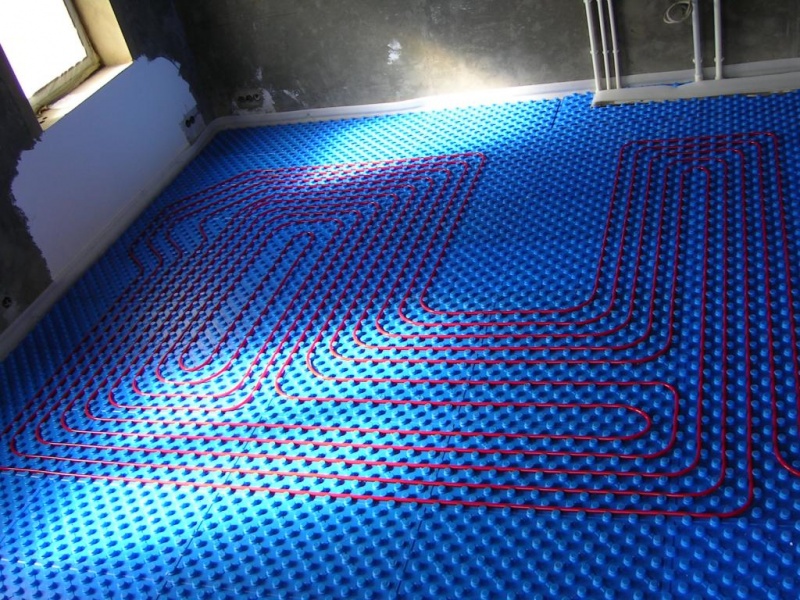

In custody

Insulation can significantly save on space heating. In addition, proper thermal insulation of the floors will ensure a comfortable stay in any building. The main thing is the selection of high-quality and environmentally friendly materials, as well as adherence to technology. If everything else is arranged by a system of underfloor heating in the room, you will be comfortable even in the most severe frost.

3 comments