Vinyl floor tiles: analysis of the pros and cons + overview of installation technology

The appearance of vinyl tiles in an extensive range of finishing materials did not become a sensation. Her invention is quite understandable from a technical and technological point of view. With systematic persistence, the developers improved practical qualities and insulating aspects, improved laying methods in the name of facilitating the process and reducing labor costs. The result is admirable: vinyl tile for the floor and design pleases, and serves an incredibly long time, and is laid without problems by unprofessional performers. Consider in detail its advantages and advantages of styling from all sides.

Content

What is this flooring good for?

The undeniable advantage of vinyl floor tiles in combining the best qualities of a number of the most popular coatings. This is a symbiosis of the flexibility of linoleum, the stability of natural stone, the simplicity and speed of construction of laminate floors.

Tiled vinyl coverings with tactile and visual accuracy imitate parquet, floor ceramics, leather trim, marble, granite cladding. There are brands due to which laying under the feet of the owners the grass can forever turn green, can remind of summer rest sea pebbles or river sand.

Vinyl tiles are distinguished from the underlying prototype development:

- durability, allowing manufacturers to safely issue guarantees for a period of 10 to 35 years;

- extremely weak abrasion, ensured by the introduction of mineral chips or quartz sand;

- resistance to UV radiation, due to which the initial color does not change at all;

- water resistance, which makes it possible to use the material for the arrangement of wet rooms, open areas, pools;

- dimensional stability, guaranteeing independence from fluctuations in moisture and temperature;

- resistance to point impacts and prolonged mechanical impact without the formation of cracks, chips, scratches, tears, dents;

- favorable price, exacerbated by the minimum cost of preparation and installation.

We will not be widely distributed at the expense of numerous decor options; they can boast both laminate and linoleum with tiles. By analogy with the mentioned coatings, the vinyl floor is not interesting to rodents, colonies of bacteria and fungi.

It is worth noting that vinyl tile was able to get ahead of its historical prototypes also in technological aspects, such as:

- convenient for the stacker size of elements that can be cut with an ordinary knife;

- geometry accuracy, which simplifies the marking;

- plasticity, allowing without complications to lay the coating in hard-to-reach areas, in areas with complex configuration, on inclined platforms;

- light weight, not pressing on the floor, not creating problems with transportation and installation;

- extremely simple arrangement schemes;

- opportunity to put vinyl coating literally on any basis without a substrate;

- insignificant thickness, not “eating up” the ceiling height.

Doubts about environmental circumstances are unconditionally rejected.Because the complete safety of vinyl is convincingly confirmed by the experience of using plastic food containers, windows, pipelines, decoration and furniture of their PVC.

Among the advantages, it is impossible not to note the resistance to fire, it is due to the increased content of the mineral component. The material accurately or almost 80% consisting of quartz sand or mineral chips stubbornly refuses to burn.

Quartz vinyl floor tiles are advanced PVC coatings that include quartz sand. This gives the tile extraordinary strength, almost zero abrasion, fire safety, moisture resistance. You can read more about such tiles in the article:https://floor.expertexpro.com/en/pol-pokritiya/plitka/kvarcvinilovaya-plitka-dlya-pola.html.

We will take care of vinyl flooring to the category of “simple-easy”. Wash-wipe can be without restrictions in periodicity and in funds. Moreover, it is often not necessary to use both household chemicals and one's own strengths, because the upper antistatic layer protects the PVC tile from attracting dust and stubborn dirt. We finish the praises of vinyl with a bold dot: it is impossible to slip on it.

As you know, ideal finishing materials do not exist. Vinyl tile is not an exception to this rule and has several "fat" minuses. So, a new coating for a certain period of time releases chemicals with a pungent odor into the air. And although manufacturers claim that the material is completely harmless, it is still not recommended to use it if one of the family members suffers from allergic reactions, respiratory diseases and weakened immunity. For the same reason, you should refrain from laying this material in children's rooms and bedrooms.

The second, no less significant drawback is the effect of solar radiation. It is possible that initially a beautiful shade will fade over time and lose attractiveness, so vinyl coatings are best used where direct sunlight does not fall.

Although manufacturers declare that vinyl is completely environmentally friendly, it is not necessary to consider it environmentally friendly. The material does not decompose on its own, which means that it cannot be disposed of in any simple way. In addition, who knows what chemical compounds vinyl can form when it enters the natural environment and is exposed to the complex effects of ultraviolet radiation, alkalis and acids. As for fire safety, vinyl tile really does not burn due to quartz filler. However, one must not be silent about the fact that at high temperatures the composite binders included in it begin to melt and decompose (this is most badly affected by low-quality materials from little-known manufacturers). The process emits extremely corrosive, hazardous smoke.

In conclusion, we propose to recall that due to its elasticity, vinyl tiles quickly squeeze under heavy weight, so this option is not suitable for those who like to move furniture from time to time.

Of course, when compared with other finishing materials, these shortcomings can not be considered fatal. And yet, unfortunately, some of the disadvantages force the consumer to significantly limit the scope of use of vinyl tiles in residential premises.

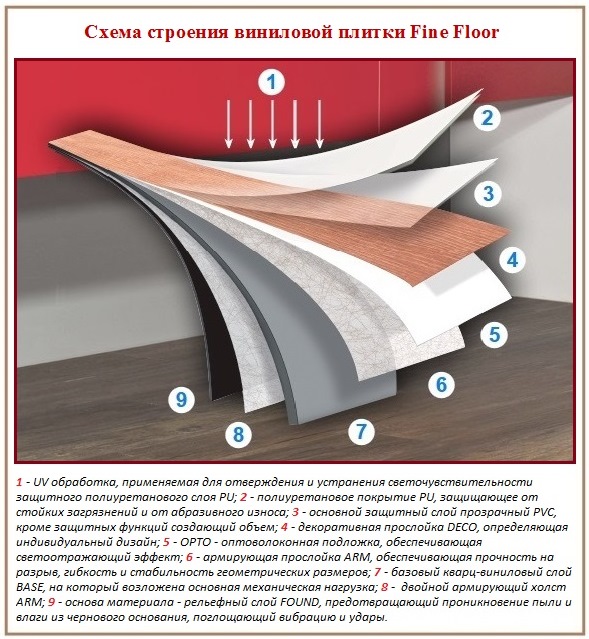

Structural types of vinyl tiles

Despite in-depth modernization, tiled vinyl coatings are classified according to operational indicators as their historical predecessor - linoleum. They are also divided into household and commercial categories with a gradation of wear resistance expressed in numbers.

The 43rd class material with the upper protective layer 0.5 mm thick will be the most durable.This figure marks commercial brands recommended for the arrangement of industrial, sports, public buildings. For finishing the floor in the apartment, a household 32-34 class vinyl covering with a transparent top protection, the thickness of which is 0.3 mm, in extreme cases 0.2 mm, is suitable.

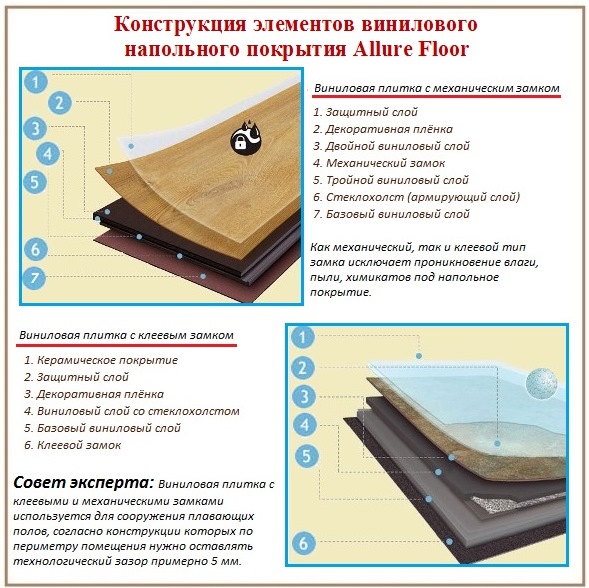

According to technological features in the list of vinyl coatings are listed:

- Self-adhesive pvc floor tiles - the most convenient type in laying. On the back of it there is a shell with an adhesive composition, providing instant adhesion to any non-loose surface;

- Castle Commercial Varietyequipped with plastic mounts of the thorn-groove system is an improved variation on the topic of a polyvinylchloride laminate that has not taken root in the people. It is used for the construction of floating floors in rooms with heavy traffic;

- Vinyl tile adhesive flooring. Based on the definition, glue will be required for laying it. This type is inexpensive and absolutely not demanding on a rough basis.

The optimum adhesive for fixing each of these types of vinyl tiles is indicated by the coating manufacturer. The given generalized classification can be supplemented with brands with specific design features, for example, with an adhesive chamfer or with butt-treated ends.

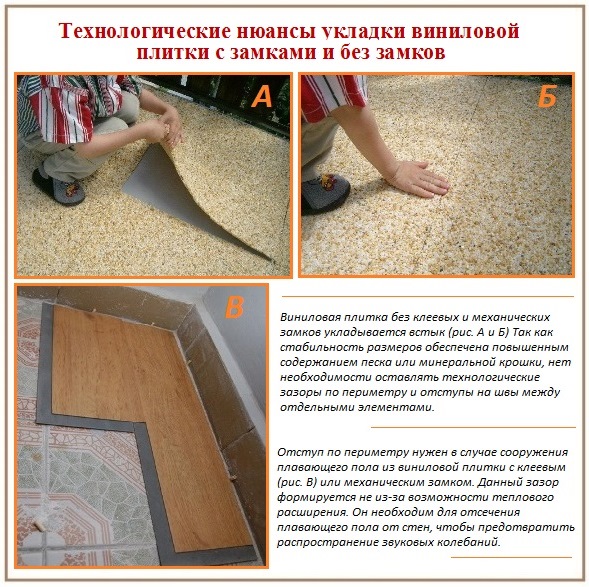

The presence or absence of a mechanical or glue lock determines the way the vinyl is laid. It is clear that for fixing self-adhesive tiles to the base, it is enough to remove the shell from the back surface, then attach it to the installation site and smooth it first with a hand around the perimeter, then with a roller completely for reliability.

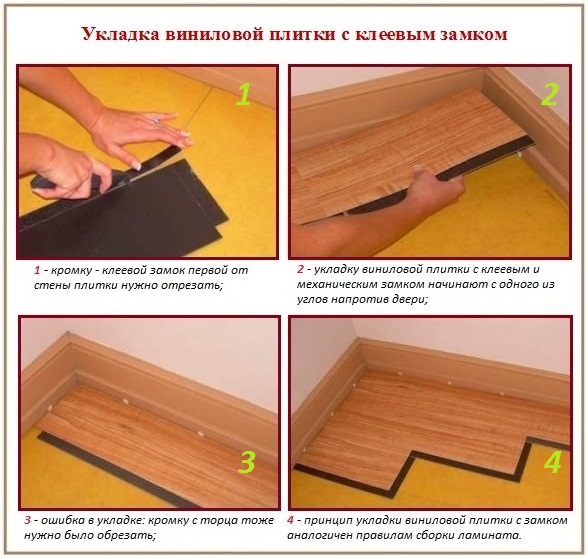

It is clear that a commercial-grade floating floor with a thorn-groove mechanical lock needs to be constructed as it is laminate flooring only without a backing. But with adhesive vinyl tiles, everything is somewhat more complicated, therefore, we will consider the rules for fixing it, especially since this material is the most affordable, which means it is the most attractive for a beginner.

One of the samples of vinyl coating is Art Vinyl - PVC tile with unusual properties. You can find a review of this material here:https://floor.expertexpro.com/en/pol-pokritiya/plitka/art-vinyl.html.

When choosing a vinyl coating, one way or another you will have a question which tile to take - with a castle connection, adhesive or free-lying. Although the first one is better in that it allows you to make almost seamless connections, I still will not recommend it because of the excessively high price tag. Sometimes the value is too high that it exceeds the price of porcelain stoneware, and he, you see, is a material of a completely different class. Experts say that this type of coating was originally developed for arranging temporary floors at exhibitions, as well as other events, and after that it gained popularity among those who like to be “expensive and rich”. I am ready to declare with all responsibility that no one can distinguish laying tile with a lock from ordinary material, which is mounted on glue, with a good foundation preparation and due care. In addition, when using the latter, you will have much less scraps, because the tile can be cut and placed on the floor in any convenient way. As for the free-lying tile, its advantages are completely incomprehensible to me, given that according to the instructions the installer must still stick every third row.

The second important point concerns manufacturers. For residential premises I strongly do not recommend buying vinyl or quartz vinyl tiles of Chinese origin. I will not argue with those who claim that China also has materials of decent quality.And yet, no one can convince me that the lion's share of the products from the Celestial Empire, which can be found on our market, is made of recycled plastic in violation of all permissible norms and rules. If you decide to lay quartz vinyl at home, then do not be stingy and give money for high-quality coating made by a famous European brand. At the same time, do not forget to check the authenticity of the material according to certificates of conformity, information on the Internet, etc.

The last thing I would like to tell you today is about laying vinyl or quartz vinyl tiles on verandas, balconies, loggias, barbecue areas, etc. Remember that even the highest quality and durable coating with a high content of quartz sand has a protective top layer from thermoplastics. And this means that when exposed to ultraviolet light, it undergoes accelerated aging. For this reason, the use of soft PVC coatings in open areas is not recommended.

Glue vinyl tile laying instruction

In general, the technology of laying pvc floor tiles on glue similar to the ceramic tile bonding algorithm. The only difference is that with vinyl elements you can easily finish concave and convex surfaces.

Because Since vinyl floor coverings are distinguished by geometry stability, there is no need to comply with technological indentation around the perimeter of the premises to be equipped, around pipes, near doorways. No need for seams between the elements, PVC tiles are laid end-to-end. An exception is a floating floor that requires clipping from walls to prevent the transmission of sound waves.

Preparation as a mandatory step

Despite the assurances of manufacturers of vinyl floors in the absence of requirements for a rough basis, there are still reservations in the instructions for their product, these are:

- humidity of the concrete base within 5%;

- thorough preliminary repair of cracks, exfoliated sections, potholes;

- the presence of a rigid, non-sagging surface constructed from plywood of GVLV or TsPS boards above the logs, if necessary, above a plank floor, parquet, concrete;

- preliminary elimination of sharp depressions and bulges by scraping, grinding or pouring the leveling mixture;

- meticulous removal of residues of oil paint, grease, dust.

In order to prevent senseless glue consumption, the porous concrete floor, the gaps between the floorboards, the joints between the ceramic elements of the old coating must be puttied.

Before gluing or before assembling a floating floor, vinyl tiles must be allowed to "stand" in a horizontal position for at least a day in an equipped room. The temperature background in the room during the adaptation of the material and installation is indicated by the manufacturer of the material, usually from 18º to 24º C.

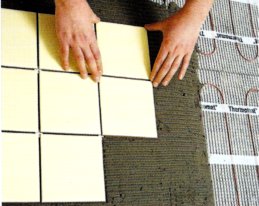

Installation of vinyl floor tiles is allowed above water and electric systems of "underground" heating. The main thing is not to forget that a week before the start of finishing the floor, the equipment must be turned off.

Between the vinyl coating and the “underfloor heating” there should be a distance of about 1.5 cm provided by a crate made of timber, polymer or cement casting. You can not stick vinyl tiles to foamed insulation and soft substrates!

Generally, old flooring before the construction of vinyl floors according to European DINs is usually removed. But since dismantling cannot be carried out “without noise and dust” ©, then a strong plank floor, perfectly laid linoleum, elastic slats and rigid plates can be left in an acceptable state. However, the material conjugated with vinyl should not contain asbestos fibers that are harmful to the health of the owners.

Want an unusual cover for your floor? Pay attention to the "liquid" tile, which is described in detail in the material:https://floor.expertexpro.com/en/pol-pokritiya/plitka/zhidkaya-zhivaya-plitka.html.

Trying “dry” by the dimensions of the room

Before starting, experienced craftsmen advise "dry" to lay out the tiles on the site intended for decoration in order to determine the starting point of laying. It does not always coincide with the center of the room due to differences in the arrangement of furniture, the presence of built-in wardrobes or large household appliances.

Having decided on the starting point, mark the perpendicular axis with the coated cord. The axial guide lines can be parallel to the walls or marked at an angle. Along one of them we will lay the tiles behind the tiles, the second is needed as a guide.

Step-by-step description of the installation process

So, here is the order of work:

- We meticulously study the instruction on the use of glue, pay attention to the polymerization time of the composition. During this period, we need to have time to attach the tiles to the surface treated with glue.

- Given the initial lack of dexterity, we are not fond of coating large areas with glue. We start with 3 m², then we reach 5 m². We use a flat spatula with V-shaped teeth for application. We glue the area near the starting point on one side of the axis.

- The end face and the longitudinal line of the first tile, on the back of which there are arrow tips, should coincide with the center lines. We apply it, iron it by hand to remove excess glue and air from under the tile.

- “Tile” tile by tile according to the selected laying pattern: “pyramid” or “layer by layer”. Elements are stacked without gaps!

- We roll the finished area of the floor with a rubber roller. The excess glue that has seeped through the joints will be removed with a damp rag. After half an hour, we’ll roll again.

Of course, we will not sit and languidly wait half an hour, after which we need to repeat rolling by a roller. At this time, we tiled with PVC tile another section, and so on until the victorious end.

Upon completion of the process of gluing tiles, we check the reliability of fixation of each element, especially in the area of corners. Doubtful elements are re-glued again. After a day, vinyl floors can be safely washed, items of your favorite atmosphere can be brought in and placed after 48 hours.

Cutting and styling tips

You should always keep in mind that:

- In the name of eliminating errors when cutting segments of vinyl tiles, markup should be done on the front side.

- The segment must first be tried without fastening to the place intended for its installation, then process the surface with glue and stick it.

- For the correct cutting of tiles, some of which will bend around pipes and door frames, you need to make cardboard templates.

The surface of the vinyl tile is effortlessly cut along the marked line with a knife. Then the element needs to be bent and complete cutting along the previously made incision.

We were convinced that there is nothing super complicated and sophisticated in the process of veneering vinyl floors. Armed with a knife, square, tape measure and putty knife, we can get down to business.

Do not forget to calculate the consumption of material, the benefit is that, taking into account cut errors and damage to the elements, there is no need to purchase 10% of the surplus, as with tiles. Enough 2-3 tiles, and go to the heights of craftsmanship!

14 comments