Vinyl Flooring: Overview of Coating and Installation Technology

It's a shame, having recently completed the repair, to find on the floor a trace of a fallen knife or a plank of parquet swollen from spilled water. Such damage is especially characteristic of the kitchen. But what to do, because I want the floor here to be not only durable, but also beautiful and pleasant to the touch. Perhaps you should pay attention to vinyl flooring - a material known since the 30s of the last century, and undeservedly forgotten recently. At the mention of this material, many recall the strange multi-colored squares that covered the floors in Soviet canteens and kindergartens. However, modern vinyl, although it is essentially the same material, looks completely different. Let's try to meet him again. Perhaps this acquaintance will be a pleasant surprise for you.

Content

Let's take a closer look

Like all floor coverings, vinyl tile has its advantages and disadvantages.

Advantages of this flooring

- Variety of colors and textures This stuff is huge. Each major manufacturer produces about 150 products. Most often, this is an imitation of wood or stone, but in the latest collections you will also find very original color schemes. So to choose a suitable drawing is not difficult.

- Cheapness. The cost of the most expensive coating of this material does not exceed $ 40 per m2, and budget models can be bought at 15, which, you see, is very inexpensive.

- Ease of use. Vinyl coating does not require additional operating costs and is easy to clean.

- Strength. Subject to the installation technology, such a floor will last you 15-20 years. Composite and homogeneous vinyl tiles are painted over the entire thickness, which means that scratches on them will not be so noticeable. And the abrasion of such material is almost impossible. The wear resistance of printed vinyl coatings depends on the thickness of the protective layer. When buying such a coating, it is better to give preference to models of eminent companies that have proven themselves in the market.

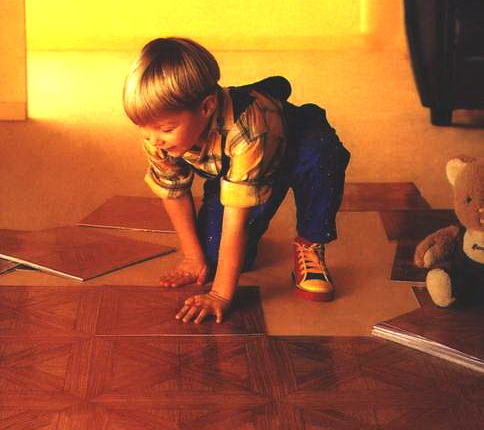

- Easy installation. Everyone can cope with laying flooring. On sale there are self-adhesive models and tiles that require the application of a special composition. Both of them are easy to put down - this process does not require special skills.

- Maintainability. If you managed to somehow damage part of the flooring, just remove the damaged tiles and replace them with new ones.

- Nice texture. The vinyl floor always remains warm enough. It is pleasant to walk on it with bare feet, and a special top layer prevents slipping, which makes the coating also safe.

Disadvantages - we analyze cons

Unfortunately, vinyl flooring also has its drawbacks - customer reviews speak of the following disadvantages:

- Toxicity of burning. Despite the fact that this material is not particularly combustible, in the event of a fire it poses a special danger.The fact is that in the process of burning vinyl releases toxic substances, by inhaling which only a few times a person loses consciousness.

- "Burnout." Cheap vinyl panels under the influence of sunlight can change color - yellow or become paler. It should be noted that the protective layer of more expensive models gives them resistance to "burnout".

- Chemical stains. As already mentioned, vinyl coatings are well washed, but there are some types of contaminants that are very difficult to remove from this floor. They occur most often in contact with rubber. This may be a trace of a rubber mat or heel heel. If you do not remove such an imprint on time, discoloration of the coating may become irreversible.

- Toxic “evaporation”. For the first time after installation, not very high-quality material can release volatile organic substances into the air with a negative effect on the human body. To avoid this effect, be sure to ask the seller for a certificate of compliance.

- Disposal Being an artificial material, vinyl coverings which have served their age do not decompose naturally. This material is very rarely recycled, which means discarded vinyl will accumulate in landfills. And the process of production of this material cannot be called environmentally friendly. Non-renewable natural resources are used for its manufacture.

- High surface preparation requirements. Being a very plastic material, vinyl coating over time takes the form of a base.

Basic rules for laying vinyl

Familiarity with the vinyl coating will be incomplete if you do not talk about its installation. Let's start with the theoretical part. Under the general name "vinyl flooring" can hide different materials. Rather, their main component remains the same - it's vinyl, but the performance can vary significantly. It can be vinyl tiles, vinyl flooring with locks flexible laminate on a glue basis or with smart tape.

Naturally, the nuances of installing each of these coatings are somewhat different. Let's look at the general styling points and focus on the differences.

1. Adaptation of vinyl coating to indoor conditions

After the vinyl flooring is brought into the house, do not rush to unpack it immediately. For some time it should be kept in order to adapt to the conditions of the room. If transportation was carried out at a temperature below 10 ° C, then you can open the vinyl-coated box only after 48 hours. If it was warmer, then after 24 hours.

In order for the installation to be successful, the room temperature must be kept at 15-26 ° C during the day before the start of work and the day after it is completed. Humidity should not exceed 60%. If you are planning to lay a vinyl coating with an adhesive base on a warm floor system, then three days before the start of work, you should turn off the heating and not turn it on for another six days after installation.

2. Preparation of the base for laying

The most important thing is that the surface is clean and dry. This rule applies to any vinyl coating, and in particular to one that glues directly to the base (non-floating installation).

In accordance with the laying technology, the moisture content of the surface under the vinyl should not exceed 5%. PVC does not allow moisture to pass through, so even a small amount of it will accumulate under the base of the vinyl and destroy the adhesive composition. Sooner or later, such a vinyl flooring will begin to fall off the surface.

You can find out if the surface humidity meets the required 5% with a hygrometer.If you don’t have it, then use the following method: lay a piece of polyethylene 1x1 m in size on the base to be checked, fix it with tape with tape and hold it in this form for 24 hours. If during this time condensation appears on the inner surface of the polyethylene, then the humidity is more than 5% - you need to dry it. If there is no condensate - everything is in order, you can get down to business.

As for floor leveling, with vinyl flooring everything is not so clear. The base for tiles that adhere to the floor must be carefully aligned. Otherwise, existing cracks and sinks on the floor are “printed” and on the PVC coating. For example, a manufacturer of design tiles Art vinyl It attaches great importance to leveling the floor and recommends using as a basis for its coating self-leveling screeds.

Floating vinyl flooring does not adhere to the base. Accordingly, it makes no sense to focus on leveling, it is enough to repair deep cracks with putty. For example, the flexible Allure Floor laminate on adhesive locks looks great on substrates with differences in height of up to 3 mm / m2. Moreover, this type of vinyl is allowed to be laid on old floor coverings without first having to dismantle them.

At the final stage of preparation, the surface for any type of vinyl coating is cleaned of debris and dust free. Any foreign particles that get on the glue or glue lock will contribute to the deterioration of adhesion of the coating to the floor surface. Therefore, it is sweeping and vacuuming, then a primer is applied, which additionally fastens the particles of the upper layer of the base and improves the adhesive properties of vinyl.

3. Laying the floor and laying the vinyl coating

For vinyl laminate with locks or glue-based floor markings, as a rule, do not practice. These vinyl coatings are referred to as express methods of creating a “quick” floor, so there is nothing superfluous in the technology of their installation. They begin to be laid along the wall farthest from the front door, starting from the corner, gradually moving to the exit.

Vinyl strips, the glue is used during installation, are mounted on a previously marked base. First, they find the center of the room, and then, relative to it, the surface is divided into 4 identical sectors. Planks or tiles begin to be laid out within the sector remote from the front door, starting from the found center of the room. First, acrylic or dispersion glue is applied to the base with a notched trowel, allowed to dry, and then vinyl is laid. Installation is carried out "on their own", that is, they move forward along the already finished coating.

4. End of work

After finishing work, check the quality of the installation. Particular attention is paid to edges and corners. If they puff at least a little, then such a coating will not last long - the elements will begin to be dismantled by themselves. It’s better to remake such a marriage right away.

If glue was used during installation, its traces on vinyl are removed with a cloth dampened with alcohol or a soap solution. It is possible to wash the floors only after a day after the end of work. And to install furniture - after 2 days. This time is given so that the adhesive used during installation is completely dry and gain strength. It is logical that a flexible laminate on an adhesive basis or with a smart tape does not need such precautions - these types of vinyl coatings can be used for their intended purpose immediately after installation.

Conclusions and related videos

It is up to you to decide whether the vinyl cover is worthy of a place of honor in your home.We can only say with confidence that this material is no worse than its competitors represented in the same price segment.