Laying a laminate on an uneven floor - three ways to compensate for base defects

Laminate is a fairly demanding coating, requiring an even and strong foundation. Altitude drops, fossae, tubercles, cracks that are on the subfloor significantly reduce its service life. They become the cause of unplanned additional loads on the lock joints of the slats. Even one hole on the base will create a “failure”, stepping on which you will bend the lamellas, testing the strength of the castle joints. Sooner or later, this will lead to the appearance of visible cracks, loosening, and possibly breaking locks. Thus, the service life of the flooring will be reduced, and the appearance from the very first day will leave much to be desired.

So what to do? Two options are possible: either apply the traditional methods of leveling the base, or use alternative methods that neutralize the negative consequences of irregularities. Consider all of these methods.

Content

Using a leveling pad

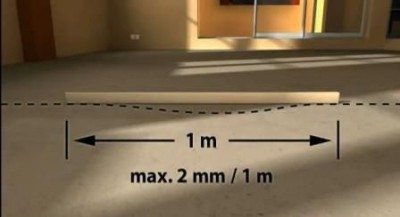

We will make a reservation right away: a surface is considered a suitable basis for a laminate, the height differences on which do not exceed 2 mm / lm. These are permissible norms of curvature at which the internal stresses of the coating are insignificant and do not lead to breakage of locks. Exceeding these numbers needs to be adjusted.

The easiest way to eliminate uneven ground is to use special substrates of:

- polyethylene foam;

- expanded polystyrene;

- extruded polystyrene foam;

- polyurethane;

- natural cork (option - from a mixture of cork and bitumen or rubber);

- wood fiber boards.

Any substrates that exist on the market can compensate for some unevenness in the substrate. The quality of the result depends on their density and thickness. For example, a conventional 2 mm thick polyethylene foam substrate evens the surface of the substrate to 1 mm / m. ISOPLAAT or Silent wood fiber substrates are more effective. ISOPLAAT slabs with a thickness of 4 mm are able to compensate for differences up to 3 mm / lm, and with a thickness of 12 mm - as much as 5 mm / lm! Roughly the same abilities and wood-fiber substrates "Quiet running."

Base alignment

In the event that the differences exceed the capabilities of the substrates, then more effective methods must be used. The most common substrates for laminate flooring are concrete slabs or wooden floors. Any of these options requires its own approach.

Concrete surface

In most urban apartments, concrete slabs form the “rough” floor. To level such a base, follow the step-by-step instructions:

- Prepare the base. Remove the old coating, clean the concrete slab from debris and dust. If there are deep cracks, pits, chips, pre-seal them with cement mortar.

- Prime the surface. Priming improves the adhesion of the finish screed and concrete base. In some cases, it is advisable to use not an ordinary primer, but a waterproofing one. This is true for repairs in kitchens or on ground floors located above moist basements.

- Perform alignment.If the base is problematic, with large elevations, then it is more practical to use the usual cement screed. Prepare it yourself (the ratio of sand to cement is approximately 3: 1) or buy a ready-made dry mixture. There should be enough water so that the consistency of the screed resembles a very thick sour cream.

- Set lighthouses (it is better to use special metal profiles that do not need to be removed after completion of work) in increments of 0.5-1 m. This step can be more if there is a long rule and a physically strong man performs the screed. Spread the cement mortar between the guide rails, aligning the screed with the rule.

- After the mortar hardens a little (2-3 hours is enough), the cement screed is evened out with a foam or wooden grater. The cement screed dries and gains strength for a long time. It is recommended to lay a laminate on its surface no earlier than after 2 weeks.

If you don’t feel like messing with a cement screed, there is a much more modern, although more expensive solution, to use self-leveling mixes.

Dilute the dry mixture in water, according to the instructions, and then simply pour it onto the base, leveling the solution with a spatula. In order to remove air from the mixture, roll its surface with a roller with rubber spikes. This will make the surface smoother without holes from small air bubbles on the surface. Mixes harden much faster than cement screed, so you can start finishing with flooring in a few hours.

Wooden floors

Perform the work according to the following plan:

- Clean up your existing wood flooring. Inspect wooden floorboards for cracks, crevices, and other defects. All this must be eliminated with putty. If the boards creak, then inspect the logs, if necessary, replace them. Fix the boards again on the lags, preferably with screws, and not with nails - this is more reliable. During this operation, some parts may need to be replaced with new ones.

- If there are significant bumps and bumps on the wooden floor, you can correct the situation by looping (grinding). The looping machine can be rented without problems, it is not necessary to buy new equipment for one-time work.

- Level the wood floor.

- After puttying and scraping, it’s possible your wooden floors are ready for use. laminate installation. Check the base level, if everything is in order, then the alignment is finished. If the irregularities are significant and they could not be fixed, it is necessary to lay plywood sheets or OSB boards on top of the floorboards. Use material with a thickness of 15-20 mm.

There is another option - pour over a self-leveling mixture. This must be done in exactly the same way as when leveling concrete foundations. At the same time, you will get an even and smooth screed, ideally suited for installation of the coating.

Replacing chipboard or fiberboard laminate with vinyl

If you do not want to carry out complex work, you can use the existing alternative to capricious material. This is a new type of flooring called “flexible laminate". It, unlike the usual dies from chipboard or fiberboard, can be laid on an existing, not even enough base.

The flexible version is available in the form of strips, each of which consists of two layers: the upper part is made of a mixture of polyurethane with aluminum oxide, the lower part is made of vinyl. The lower part is offset from the upper by a couple of centimeters, forming a free thin vinyl layer around the perimeter. A smart smart tape is applied to it, thanks to which the strips are glued to each other at the ends.A “floating” floor structure is formed without direct attachment to the base. Therefore, pits, knolls and cracks will not be “imprinted” on such a coating, unlike adhesive-based vinyl tiles.

Video: leveling the floor under the laminate

A smart tape connection is called an adhesive lock, similar to Click and Lock mechanical locks. However, the adhesive joint is more flexible, so it will not break on the unevenness of the floor. For example, an Allure Floor vinyl laminate withstands base drops of up to 5 mm. At the same time, the resulting coating in appearance is no different from a standard floor covering or wooden parquet. And in terms of performance, it even wins. Vinyl, unlike wooden counterparts, is absolutely moisture resistant and much stronger, which is confirmed by strength class 42-43.

4 comments