Laying a laminate on a wooden floor: preparing the foundation and carrying out work

In a fairly extensive list of flooring there are not too many options compatible with a base of wood. True, observing special rules, you can lay almost everything. But the laminate floor, built on a floating principle, is ideal for arranging a house erected over a structure of beams, logs, boards. However, compatibility does not save independent craftsmen from studying the nuances according to which the laminate is laid on a wooden floor, and from the need to remember the specifics of eternally moving wood.

Content

Can laminate floors be laid on wooden floors?

Laminated panels rally only among themselves, it is not necessary to fix them to static building structures, that is, to the floor or to the walls. The floor, constructed in a floating pattern, lies loosely on a draft basis, allowing it to expand and contract. And it, in turn, does not prevent the laminate from changing geometrical parameters, following changes in the temperature background and humidity fluctuations.

The structural specificity of the laminated board provides an opportunity to dispense with adhesive compositions that hermetically seal butt joints. Although the adhesive technology exists, it is rarely used because of the complexity, the significant consumption of glue and the inability to disassemble and reassemble forever docked panels in another place. The bezkleevoy, the most popular method of fastening pleases both the wooden base and the owners of suburban property with the excellent spontaneous aeration necessary for ventilation of the components of the wooden structure. Perfectly ventilated through the seams, the floor covered with a laminate serves longer and does not rot.

Despite the artificial origin of the laminated coating, its behavior during operation is not much different from the behavior of lumber. After all, its main element is made of MDF panels, particleboard, HDF and similar boards created by pressing wood processing products. The basis of the laminate floor is an important characteristic that determines the scope of use of the material. In principle, laminate is not recommended to be installed in rooms in which wet cleaning should be regularly carried out. The arrangement of bedrooms, children's rooms, offices, living rooms is allowed. However, a coating made using HDF is considered moisture resistant and can be laid on the floor in hallways and even in kitchens.

Note. For flooring in rooms with a characteristic wet mode, a class 33 laminated floor on a wear resistance scale is suitable, but it rarely suits the owners of suburban housing.

Rules for preparing a wooden base for laying

There are general requirements for the characteristics of the equipped surface. According to the instructions of SNiP with the assigned normative collection number 3.04.01-87, for laminate flooring:

- a level surface is required, the relief of which does not exceed 2 mm within a 2 m² area;

- let's say max slope is 4 mm, evenly distributed over 2 m in any direction.

It is not necessary to depart from the instructions regulated by technical regulations, since in case of non-compliance the sensitive locking system will be damaged.Grooves will shake, fragile thin crests will break, the floor will not last long, it will be necessary to rebuild.

You can, of course, partially change the elements if only a few boards are damaged, but the repair procedure will require a lot of effort. In such situations, the laminated panels are dismantled to the place of restoration, then the broken elements are replaced and re-laid in the reverse order. With multiple damage to the laminated planks, partial replacement can not be discussed. In the best case, several planks can be saved that can be used to equip pantries, closets, compact covered verandas.

Before flooring the laminate panels on a wooden subfloor, an audit of the base is mandatory. The scope of work is determined, as a result of which the fully-ordered base will be ready to put on its reinforced “shoulders” coating.

Preparation steps depend on the degree of wear of the wooden structure:

- Old plank floor will have to be disassembled to a support beam, because over the years of its many years of operation, sensitive natural organics could suffer from an excess of moisture or become infected with a fungus. Find out through the floorboards what the real state cannot be, if the wooden floor is not the ceiling of a spacious basement. Those who have a high underground are lucky. It will provide an opportunity to examine and repair the details of the floor without the tedious dismantling. The entire list of structural elements is carefully examined. Doubtful sections of beams and logs are cut out, replaced with a new beam. Planks removed from the low-subfloor floor, inspiring confidence in reliability, are turned upside down with an unclean underside, we are again laid, we fill the cracks with foam or repair compound. Old worn boards change without regrets. On the floorboards fixed in sweat we will “walk through” the cycling machine. All structural components of a long-constructed wooden floor must be carefully treated with antiseptic impregnation and flame retardant. Now it’s easy to buy mastic that performs both functions that are significant for wood.

- New plank floor there is no need to scrupulously diagnose, since it was built not so long ago, it is probably covered with compounds that protect against putrefactive bacteria and from fire. Therefore, preparation for laying laminate flooring on a newly constructed wooden floor will not take away a lot of time and labor from the artist. We check the fasteners, change or renew the loose fasteners, “stoke” nails or self-tapping screws a couple of mm in the floorboards. We foam or fill with wood glue, mixed in half with sawdust, cracks, if necessary we loop.

- Sexually impaired need to be finalized. It is very difficult to determine the range of actions in such cases in advance, because the situation can have a lot of various reasons. For example, if the floorboards bend, the lag system will have to be strengthened by additionally installing the beam or replacing the boards with thicker material. It is often more profitable and easier to lay on top another row of boards of the same thickness, laid “in a cross” in the previous layer. The latter measure is permissible if the additional draft floor together with the laminate and the substrate does not take away from the ceiling height too many very necessary for a limited space, see

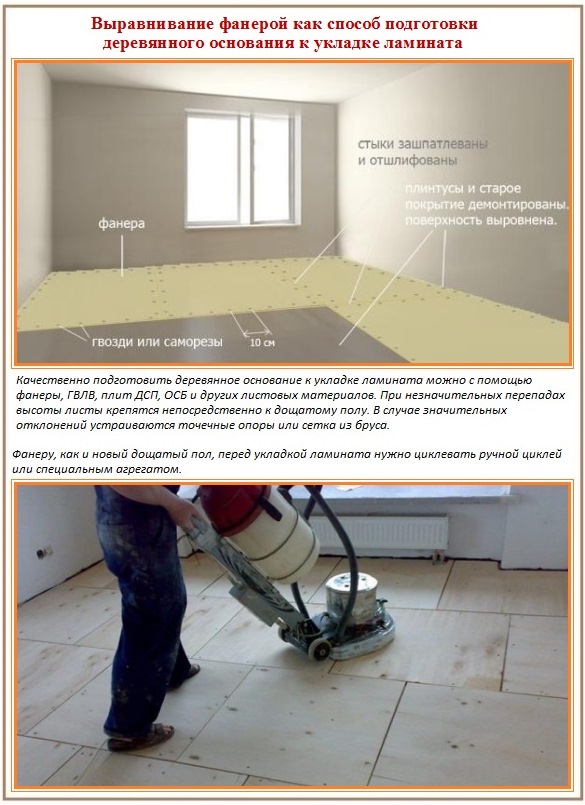

Topic article: Aligning the wooden floor with plywood: all about laying plywood on a wooden base

You can evenify the rough base of wood with plywood, GVLV, OSB sheets or by lining pieces of roofing material under the logs, as well as rolled up glassine in several layers. You can purchase a “designer” from Knauf with a full range of fasteners, supports and plywood sheets. The method is chosen based on economic considerations and ease of implementation.

The technology of laying laminated boards

We offer you to familiarize yourself with the thematic video:

It is impossible to cover the wooden draft base with steam or waterproofing, it will interfere with ventilation. Condensation harmful to the wood will accumulate under the insulation. But if the ardent desire to isolate nothing could not break, it is better to use a diffusion membrane.

Before laying it will only be necessary to lay the substrate, it is advisable to choose a natural material for this. For the sake of preserving the wooden structure, it is worth forgetting about the height of the prices for cork and the bitumen-cork or bitumen-rubber pressed options created with its use. The thickness of this layer is chosen, focusing on the same parameter of the laminated panel. Usually, under an 8mm laminate, stripes of a 3mm substrate are placed without overlapping. No stationary fastenings to the walls or to the base are needed, only gluing with adhesive tape with periodic dots or solid lines.

Note. The choice of the direction of the layout of the laminated dies is affected not so much by the preferences of the owners, but by the direction of the existing floorboards. Laminate panels should lie across the boards. So, under the coating strips of the substrate should be laid along.

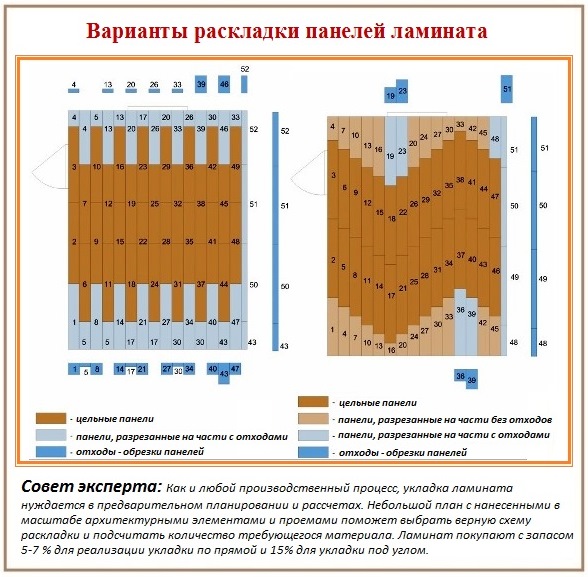

Suppose it has already been decided how we lay the laminate panels, a simple outline by hand is drawn in advance and a rational scheme is chosen. Information on the methods, rules and layout options abound on the site. Here are a couple of articles on the topic:

- How to lay a laminate: attention to layout options + step-by-step instructions

- Diagonal laying of the laminate - technology and nuances of the diagonal installation

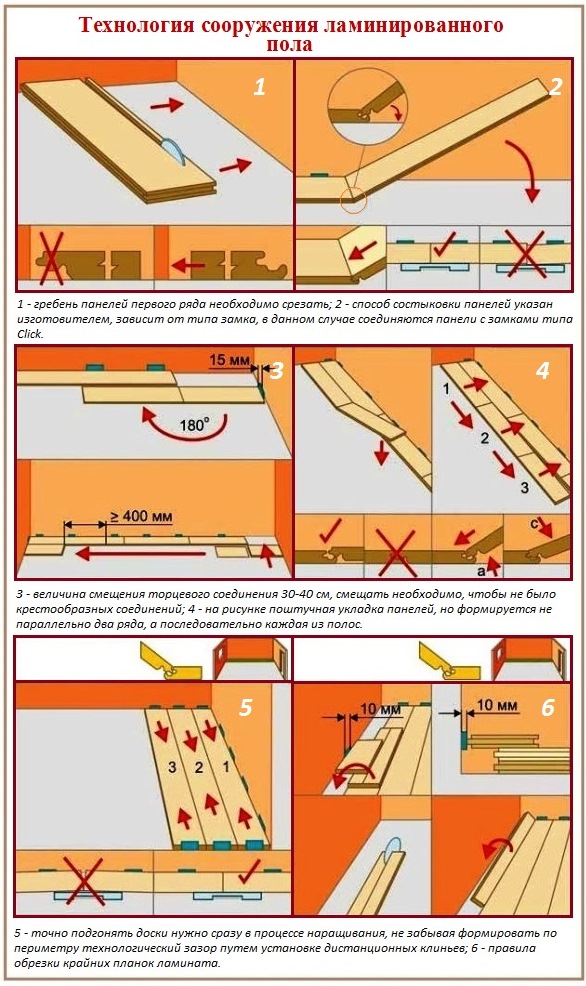

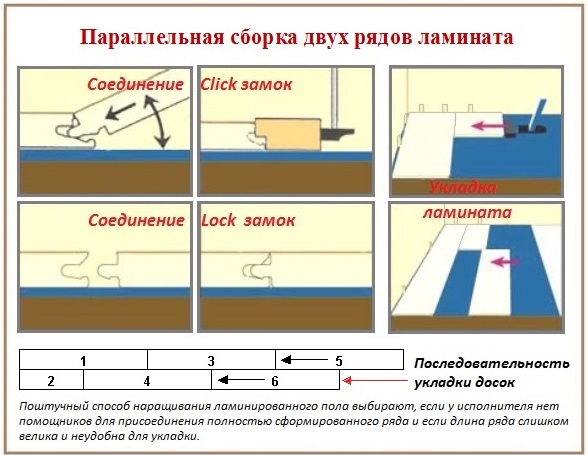

Docking boards can be, gradually increasing the coverage of each piece separately or docking pre-assembled rows. The preferred method is usually indicated by the manufacturer of the material, and we will examine the piecewise algorithm.

Stacker actions for piece-by-piece assembly of a laminate floor:

- We are located in the starting corner, usually the one farthest from the doorway, taking 4 panels with us. Two of them (1st and 3rd), planned to be laid against the wall, must first cut the comb. We don’t touch the groove; it is always aimed at the stacker.

- First, we outline how far we will move the panels in adjacent rows in order to avoid cross intersections and thereby increase the reliability of the joints. The recommended indentation for the offset is not less than 30 cm. Here by this value and shorten the second board.

- By the method specified by the manufacturer, depending on the type of the Click or Lock system, we dock the 1st and 3rd panels, then attach to them a section of the 2nd board, then the 4th uncut die.

- We move the assembled floor segment to the designated place, installing between it and the adjoining walls distance spacers-spacers with a thickness of about 1 cm. They will provide the clearance required by the laminate for movement during thermal expansion.

- We increase the first row with the 5th board with a trimmed crest, then we extend the second strip of coating with the 6th.

- By analogy, we follow until the victorious completion of the laying of the first two rows, not forgetting to trim the comb turned to the wall. We cut the boards that finish both strips according to a precisely measured distance. To snap the last in the rows of elements we use a special mounting bracket.

- Then we follow the course we studied, only the ridges no longer need to be cut.

- The panels of the last row are measured at the place of installation and cut off taking into account the temperature indent, we attach and snap using the clamp-clamp.

Pipe bypass methods, laying methods under the batteries and arranging doorways comply with the standard rules for laminate flooring.

An important point. In a large room, the temperature gap must be left not only along the walls. It is formed every 10 m, measured in width, and 8 m in length. The temperature seam is left in the opening along the axis of the closed door leaf. The clearance after installation is closed by a profile made of plastic or aluminum.

Absolutely simple rules that explain how to economically lay a laminated floor with your own hands will help to perfectly finish suburban and urban property. And for those who were not going to do their own arrangement, knowledge of the technology will help to competently monitor the actions of not always diligent builders.

5 comments