How to make a floor in a bath with water drain: analysis of 2 options for classic designs

Each owner of the land allotted for the cottage or the construction of a country house, wants to have a good bath on it. When erecting this building, beloved by many, many questions arise, among which the floor in the bath does not last. Rather, its correct device, which would allow water to freely leave without stagnating on the floor. Would you like the floors in the bath to always be warm? You do not know how to make the floor in the bath dry, warm and not slippery? So, you need to study this issue well, ask experienced builders, take a closer look at the arrangement of floors in the baths of friends. Video tutorials posted online can also help.

Wooden floors in the bath - advantages and disadvantages

Previously, it was decided to lay the floors in baths from boards, which were laid directly on the rammed earth, and later they began to use logs for fixing them. Wood is considered to be the warmest, most reliable, affordable and relatively durable material used since ancient times for the installation of bath floors. Wooden floors are still in demand, although many worthy competitors have appeared on the building materials market. For what virtues do Russians like a wooden floor and enjoy laying it in their baths?

The benefits of plank bath floors

- compliance with environmental requirements, because wood is a natural material that does not harm human health;

- aesthetic appeal, emphasizing the good taste of the bathhouse owner and his desire to continue Russian traditions;

- low financial costs in comparison with the device floors from other materials;

- speed of installation.

Technologies for the construction of a wooden base

When installing a plank floor, one of two technologies is selected. The first involves the construction of a leaking floor, in which gaps are specially left during flooring, through which water flows. Sometimes instead of cracks in the boards, round holes are drilled in the place where water accumulates. The main disadvantage of this floor in the bath is that it is always cold, especially in winter. Therefore, experts recommend laying such a floor in a bathhouse, built only in warm regions.

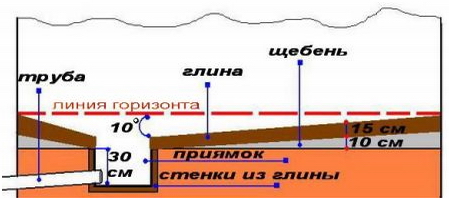

In areas with a harsh climate, it is better to use the second technology, which allows you to arrange a non-leaking wooden floor, while organizing the outflow of water through the pit through a sewer pipe into a well located outside the bathhouse. With this design, the floor surface is constructed under a slight slope equal to 10 degrees. This slope allows water to flow down to the ladder, through which it rushes into the pit, connected to the cesspool or septic tank with a wide pipe, produced for the installation of sewer networks. The diameter of the pipe should be 150 or 200 mm. Such a cross section will provide a large flow capacity of drains per unit time.

How to make the floor depending on the soil?

The work begins with the preparation of the foundation, the construction technology of which depends on the chosen method of water removal from the washing compartment of the bath.With the installation of a leaking floor, the drain can be organized in two versions, depending on the type of soil under the bath:

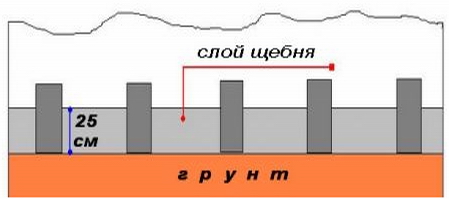

- If the soil on which the bath is installed is sandy, then a 25-centimeter layer of crushed stone is poured under the floor to drain drains. This drainage provides quick absorption of water into the soil, thereby preventing its stagnation under the coating. The organization of timely drainage of runoff water slows down the process of decay of the boards and lags on which they are filled.

- If the soil is clayey and does not have good absorbency, then the discharge is more difficult. We have to arrange a clay castle, build a pit and lay a pipe that drains water from it into a septic tank, which is periodically pumped out by a sewage machine. For the construction of a clay castle, the surface is covered with a 10-centimeter layer of crushed stone, on top of which a clay layer 15 cm thick is laid. At the same time, a slope is attached to the clay layer, the value of which should not be less than 10 degrees. Naturally, the slope is made towards the pit, which is constructed in the form of a square pit, the walls of which are also coated with clay. A pipe is mounted in one of them.

Important! Clay can be replaced with concrete, if there are funds for the purchase of ingredients for its kneading. Also note that in the case of non-leaking floors, the drain is arranged only according to the second option.

Laying logs and flooring

Laying the lag is carried out on supporting chairs, which can be made of brick with the obligatory construction of a monolithic concrete platform for each of them. At the same time, they dig a hole, the depth of which should be about 40 cm. The length and width are determined by the size of the support chair, adding 5 cm from all sides. Sand (10 cm) is poured onto the bottom, spilled with water and compacted. This is followed by a layer of crushed stone (15 cm), which is also carefully tamped. Next, arrange the formwork, in which two layers of concrete are poured, between which a piece of the masonry net is laid. All supports should be on the same level. When the concrete sets and picks up the required degree of strength, work is carried out on waterproofing. In this case, a layer of molten oil bitumen is applied, on top of which roofing material is laid.

For a leaking floor, the logs are laid at the same level, and for a non-leaking flooring, it is necessary to create a 10-degree slope using the notches in wooden blocks, which increase as you approach the pit.

In the first case, the floor is laid from edged boards, and in the second - sheet pile boards. And at first they build a draft floor, which is covered with glassine, and expanded clay is poured on top of this insulating material, acting as a heat insulator. Waterproofing material is also laid on top of expanded clay.

Important! Properly arranged wooden floors can last a maximum of 7-10 years, provided that antiseptics are used.

Do concrete floor?

If you want to create stronger floors, then use an alternative method. Masters who can work with concrete solutions do not need to explain how to fill the floor in the bath. The main advantage of a concrete floor is a long service life of up to 30 years. Aesthetic attractiveness of the floor is achieved by laying special tiles or wooden grilles.

Important! System use water or electric underfloor heating, laid under a concrete screed, allows you to provide the required level of temperature of the flooring in the bath.

If you understand the technology of work, then you can safely get to work. However, one should not underestimate the complexity of these construction works, so it is still advisable to enlist the help of professionals.