We make a plank floor: 3 options for the construction of the base of the boards + minor repairs

The tree was widely used in construction in ancient times, is popular now. But now he has to compete with new materials, the scope of which is constantly expanding. In particular, artificial materials are increasingly being used as flooring, but many people consider a wooden flooring to be an outdated, outdated option. But it is not so.

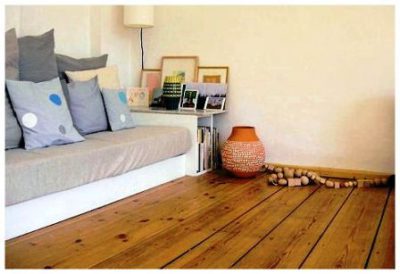

A correctly laid plank floor looks great in a wooden house, harmoniously fits into the interior, made in the style of a country. It is durable, warm, environmentally friendly, easy to care for, which allows it not to lose ground and in many cases to remain the best option.

Content

Preparation for laying the base

Flooring and flooring is best done at the end of the heating season. In summer, this procedure is carried out in dry weather, it is desirable that it be kept for at least a week, which guarantees normal air humidity in the room.

The order of technological operations that will need to be performed when installing the floor is as follows:

- laying logs on the base;

- decking boards;

- floor cleaning, surface cleaning;

- installation of baseboards and ventilation device;

- finish.

It is necessary to begin with the choice of material, tools and preparation of the foundation.

For the installation of wooden floors, a grooved board made of coniferous wood (if, larch, pine) is excellent, which has good performance and attractive appearance. This is the best option in terms of price and quality, oak or walnut floors will look much more presentable, but the price of such pleasure is much higher. Boards for flooring are chosen with great care. They must be dry, without chips, cracks and other defects. If you plan to cover the floor with varnish, then special attention should be paid to ensure that the wood is with a beautiful texture, dense, without stains and other flaws.

Before laying the floor, all wooden elements need to be treated with special antiseptic and other drugs to protect them from rot, insects and fire. Boards are treated with a solution only on the underside, since they are coated with varnish, paint or other compositions with protective properties on the outside.

In addition to boards from materials you will need: logs 5/5 cm of a standard length of 3 m, insulation, soundproofing substrate, nails, anchor bolts, self-tapping screws. The standard set of tools that may be necessary for this type of work includes: level, saw or jigsaw, hammer, drill or screwdriver, ax, nail puller.

Board flooring options

After all the materials and tools are prepared, you can begin to perform work. If this is your first time planning to lay a plank floor with your own hands, you can start from a small room: a balcony, a storage room, etc., in order to acquire the necessary skills, understand the basic principles and methods of work, and figure out how to level the plank floor if such a situation arises. need.

Option # 1 - laying the wooden floor on the logs

On a flat concrete base, the wooden floor is laid on the logs, which are bars 5/5 or 4/6 cm. They are aligned strictly horizontally (you must use the level), a soundproofing substrate is laid under each. They are attached to the base at a distance of 50-60 cm from each other, using screws or anchor bolts. All logs should be on the same level, this is checked with the help of an even bar, which is laid on several neighboring logs, then the gap between them is estimated.

First, lags are installed at the opposite walls of the room, perpendicular to the direction of the light falling from the windows. And in rooms in which movement is carried out in a certain direction, for example, in corridors - across the direction of movement, so that the boards, respectively, are located along.

Next, directly laying wooden planks, that is, boards. They usually start it from the corner of the room. The first row is placed with a tongue against the wall, leaving a small gap (about 10 mm), which plays the role of a deformation seam, necessary when the wood expands or dries. The following boards are usually stacked with an offset relative to the first row (staggered), thus achieving greater decorativeness and reducing the amount of waste. The adjustment of the boards is carried out tightly with a hammer and trimming the bar. Then they are attached to the logs using self-tapping screws or nails.

If a non-grooved board is used, which, of course, is not desirable, then pay attention to the tight fit of adjacent boards. The permissible gap between them is not more than 1 mm. Usually they are laid in one layer, nailing or screwing with screws. Nails are driven into the corner of the ridge obliquely in the direction of rallying, the hats are drowned with a damper. The length of the nail should be 3 times greater than the width of the board.

Option # 2 - laying floors on adjustable logs

If the base is uneven, and the height differences are quite significant, you can apply the technology of arranging the floor on adjustable logs. It saves installation time, places all the necessary communications under the floor, reduces the load on the supporting structures, and provides good thermal insulation.

The technique for assembling such structures is simple: holes are drilled in the prepared logs (at a distance of about 40 cm), into which the stand bolts are screwed, the logs are placed on the base, in increments of 50-60 cm. The level-aligned logs are fixed to the base with dowels, which must go through the racks. In the end, the protruding excess parts of the racks are cut off. Boards are laid on top, as in the first case.

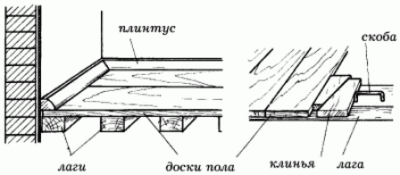

Option # 3 - laying floorboards using squeezes

To unite the boards, compresses of various types are quite often used: a squeeze bracket, a construction bracket, a wedge compression with a movable bracket. For this, wooden wedges are required, the thickness of which is equal to the thickness of the floor boards, and the taper is 15 - 20 °. One of them will be a gasket, and the other will be a worker. The working wedge must be made of hardwood. This procedure is performed as follows:

- after laying and fixing the first board, another 10-15 are placed next to it, connecting them closely;

- no less than two clamps are installed at the last board at such a distance that the narrow side of the wedge is placed between the boards and the clamps;

- gradually, from one squeeze to another, the wedges are compacted with a hammer so that the boards are joined together tightly, without the slightest clearance;

- after rallying, nails are hammered into the face at an angle, recessing the hats into the wood.

Particular attention should be paid to neatly connecting the ends of the boards to each other, they should be placed on the lags, avoiding the formation of cracks.After the boards are laid, the gaps between them and the wall are covered with a plinth, and ventilation holes are made in two opposite corners, closing them with stainless steel grilles (each area is 20-30 sq. Cm).

Although the material for the floor is selected very carefully, but defects still happen, for example, it is not uncommon for uneven floors and sagging boards. Alignment of the wooden floor is carried out using the operation of the sharp, which is performed, most often with special grinders or an electric planer. With a small amount of work on laying the floor and owning the appropriate tool, manual guarding can be performed. Before the start of this procedure, the floor surface is thoroughly cleaned, after it too.

Features of the device rough wooden floor

Sometimes, in order to maintain a soundproofing layer and thermal insulation, so-called black floor. They come in two types: stylish plank floors and typesetting. The first option is often arranged in the attic floors. It is a continuous flooring of boards, timber, nakatnik, which is laid on top of the beams.

The thickness of the material is selected depending on the filler. The boards are joined together in a quarter and nailed to the beams. When arranging a type-setting black floor, the non-long boards or plates, which rally into a quarter, are laid on the bars nailed to the beams.

Fix the plank floor on our own

One of the advantages of a wooden floor is that the repair of the wooden floor can be done with your own hands. At the same time, no special expenses will be required, and the result will please for a long time.

What are the most common defects and how to repair a plank floor?

- Sometimes plank owners complain about creakthat occurs when walking. There are several ways to fix this problem. In most cases, it is enough to simply drive a nail into the floorboard, which creaks, while it is advisable to ensure that the appearance of the floor is not damaged, and the hat does not stick out above its surface.

- Another common defect is education. slots between the boardsdue to their drying out. This problem is more difficult to solve, you need to carefully so as not to damage the logs, pull out nails with a nail clipper and remove old boards. Inspect them, rotten and rotten to replace with new ones. If the boards are in good condition, they are laid anew close to each other, rallying the entire floor area. Sometimes small cracks are filled with putty.

- If there is a need to replace a small area of the floor or even one board, then this is possible. The old board is carefully removed, and a new one, suitable in size, is selected in its place. It is attached to the lag with nails, and then, if necessary, is trimmed into a level with the rest of the floorboards.

- If the boards under your feet are too springy, then you will need to reposition the entire floor in order to be able to add a few more lags, reducing the distance between them, which will give the floor additional rigidity.

If you are attracted to natural materials that give cosiness to the room and give it a special atmosphere, if you want to get a solid base that is resistant to mechanical stress, then the plank floor is worthy of your attention.