How to insulate the subfloor and not remove the finishing boards?

Having wintered for the first time in a new house, we found that it has very cold floors. Examination of the underground showed that besides the finishing boards, there is nothing more. That is, at a distance of about 1.5 m from the ground there are logs, and boards of the finished floor are nailed to them. I don’t feel like tearing the floor in the whole house - then I’ll have to do cosmetic repairs, but there’s no money for it. Tell me, is it possible to somehow insulate the floor from below? You can get there only through the hatch, 1 m / 1.3 m in size. It is necessary that the materials “pass” and that it is possible to work with them in a limited space.

In your situation, tearing the floor is not necessary. It is quite possible to insulate it from below. The work, however, has to be quite unpleasant.

There are two ways to produce such insulation:

Method number 1

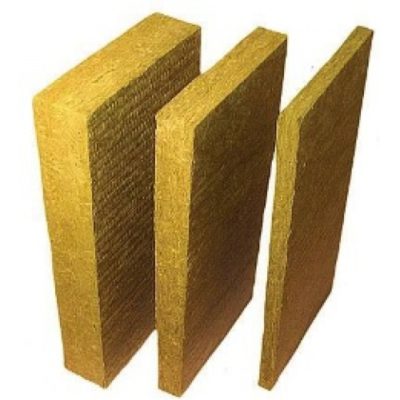

The first method involves the use of any mineral wool insulation. Better if it will be in plates, but not in rolls. But if you really need a very budget option, you can use the latter.

The width of the plate or roll should be several centimeters greater than the distance between the lags. This is necessary so that the insulation "sits" tightly. By thickness, it is better to take the material 30-50 mm thinner, lag. So that there is an air cushion between it and the finish floor. You can use a thin insulation in several layers. Then you need to lay it with an overlap - so that the joint of one layer is overlapped by a sheet of the second.

So:

- We insert a heater into the space between the lags;

- If it falls out, we attach from the bottom to the self-tapping screws with large hats pieces of an ordinary rope. They will support mineral wool.

- We stretch the vapor barrier film. It will not allow moisture from the ground to destroy the stove, and at the same time provide normal ventilation.

- Then we stuff the boards onto the logs, but not in a continuous layer, but "in a run." They are intended only to maintain insulation.

With a very small budget, you can do without boards - enough ropes.

Method number 2

The second method of warming such a floor will cost you a little more, but it is much easier to implement.

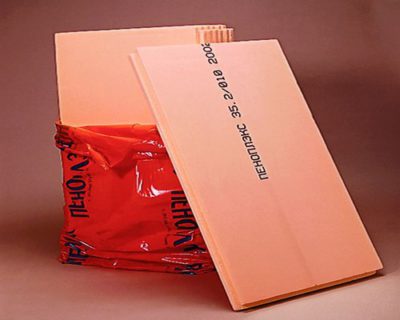

In this case, EPS is used as insulation - extruded polystyrene foam.

Simply cut off the pieces of the required size, insert them between the lags, and blow out the joints with foam. This material can also be put in several layers with overlaps.

EPPS is not afraid of moisture, which means that you do not need to do a vapor barrier. You can fix it with screws directly to the boards of the finishing floor.

4 comments