How to lay tile on a wooden floor: an overview of basic laying options

The fervor of those who wish to cover the wooden floor with ceramic tiles usually cools the “ice shower” of the incompatibility of the base and cladding materials. It is common for wood to expand, narrow, changing dimensions from the instability of the wet-temperature background. Floor ceramics that are too sensitive to linear movements will render the zealous movement of lumber unsuitable. Cracks, chips will appear, seams will crumble, elements will detach from the base if the independent performer does not know how to carry out the work correctly. The listed troubles will not threaten the masters who have learned the secrets and rules of ceramic flooring.

Content

Why it is undesirable to combine ceramics and wood

Facing wood floors with a ceramic coating is reasonably considered not a very reasonable undertaking, because:

- to cover a “warm” tree with a “cold” tile does not make much sense;

- under water-repellent floor ceramics planted on tile glue, the tree hardly breathes, because of which it begins to rot and collapse;

- the service life of building ceramics significantly exceeds the operational terms of the beam and boards of the rough basis;

- strong, slightly abradable ceramics easily pricks with linear expansion of neighboring elements;

- wooden floor does not differ in static required for laying ceramic products.

Wood can lose tiles in aesthetic terms, but even this is not a very convincing argument. After all, tiles are mainly used not because of the beauty of the picture, but because of the sanitary and hygienic advantages. Using it as a protection for wood floors from moisture is a moot point, although it can be the reason for ceramics in a wooden bath, in the shower, in the kitchen or in the combined bathroom. In general, where constant wet cleaning is needed.

Suppose there is a reason, there is material and a desire to lay a ceramic coating on a wooden base. It remains to find out how and in what ways this can be done, and choose a rational technology.

The laying of floor tiles in the new house should be flatly abandoned, as well as the arrangement of floors with new wood floors in any other building. It is necessary to wait until the end of intensive shrinkage. This is 2-3 years at least.

How to put ceramic tiles on a wooden floor

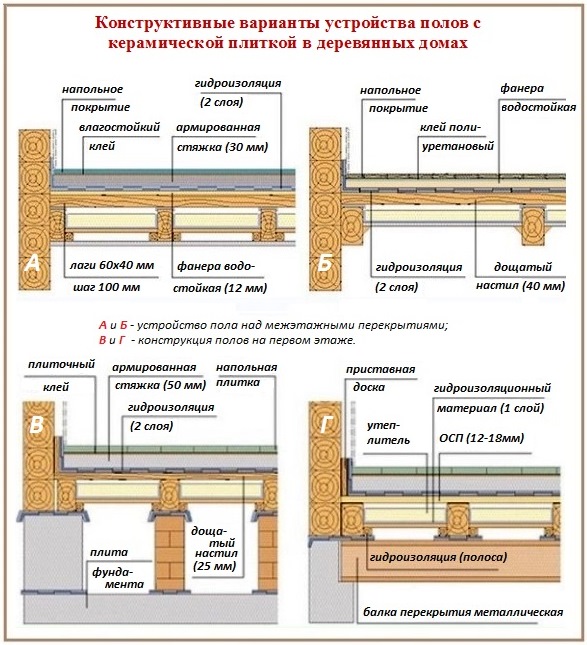

A wooden floor is a sandwich sandwich made partially or completely from lumber. The enumeration of all the variations on his theme will be unnecessarily lengthy; we will consider only common types. To carry out work on arranging a wooden floor, home masters mainly get:

- only logs left after dismantling worn floorboards and damaged substrate;

- flooring from moisture-proof plywood, sheets of OSB or chipboard, of course, with lags under it;

- the plank floor is in good condition, i.e. not new (!), but slightly worn-out construction with a floor covering.

The number of repair operations, and not the choice of arrangement scheme, depends on the condition of the floor inherited “in inheritance”. Becausethe process of attaching ceramic components to any type of surface is carried out according to the standard algorithm, all the differences are in the preparation.

In any case, you will need to create an even, strong and relatively static base, suitable for laying ceramics. Consider how.

A wooden floor must be prepared for laying tiles. In the next article, we will describe several ways:https://floor.expertexpro.com/en/pol-pokritiya/plitka/texnologiya-ukladki-plitki-po-derevyannomu-polu.html.

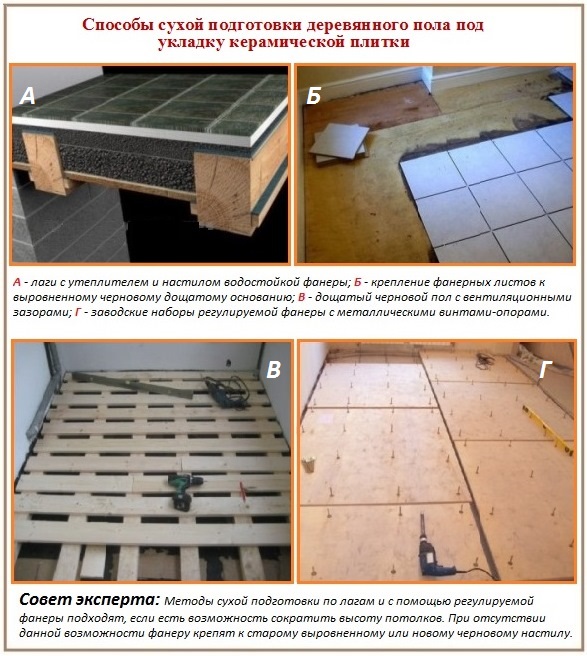

Method One: Dry Alignment

The most common and technologically sound way to level floors. At the same time, a relatively stable draft layer is formed from moisture-proof plywood or similar sheet material suitable for laying flooring. To implement dry alignment, there are many different methods, such as:

- ready-made sets of adjustable floors with screw plastic supports, thanks to which you can install logs or immediately plywood sheets in a matter of hours;

- independent construction of a system of logs or point supports on top of a “strong” plank flooring with subsequent laying of sheet material;

- flooring of a duplicate plywood layer on an existing plywood substrate;

- fastening of plywood, GKLV, OSB, cut into quarters, with self-tapping screws directly to the aligned floorboards.

It is clear that the final touch of dry preparation will be a chipboard, plywood or similar, due to which it can be made laying tiles on the wooden floor.

Sheet products pressed veneer or wood waste can not be considered completely unsupported by linear movements. True, they do not show agility equivalent to wood. However, for fixing tiles on top of leveling sheets, it is necessary to purchase a two-component polyurethane adhesive composition that is flexible and not ordinary tile adhesive.

Before fixing ceramic elements, the created plywood coating is ground along the seams. Then the joints between the elements are filled with sealant or glue purchased for the upcoming work, the surface is treated with a primer that is compatible with it.

The advantages of dry methods of creating a substrate:

- the ability to improve insulation by laying of insulation: polystyrene foam, mineral wool, expanded clay filling between lags;

- minimum load on wooden floors, not differing in reinforced concrete strength;

- speed of execution, lack of technological interruptions, significantly “delaying” the repair.

Cons are. Dry alignment is sure to “eat” part of the ceiling height. A difference will appear between the finished and unfinished part of the floor, which will have to be decorated under a step or a small threshold.

Please note that according to construction rules, the floor in hygienic rooms must be underestimated by at least a couple cm, so that in case of emergency or accidental leaks, water does not flood the floors in adjacent rooms. So, if after dry leveling, to which the thickness of the ceramic coating should be added, the surface rises significantly above the surrounding floor, the use of dry technology is undesirable.

You may be interested in a detailed guide to laying ceramic tiles on the floor, which you can read here:https://floor.expertexpro.com/en/pol-pokritiya/plitka/rukovodstvo-po-ukladke-kafelya-na-pol.html.

Video: adjustable floor system

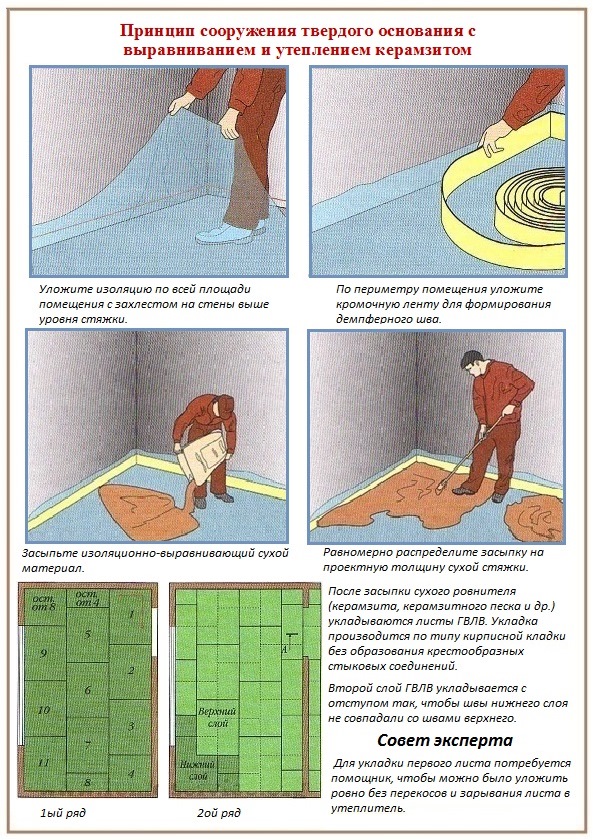

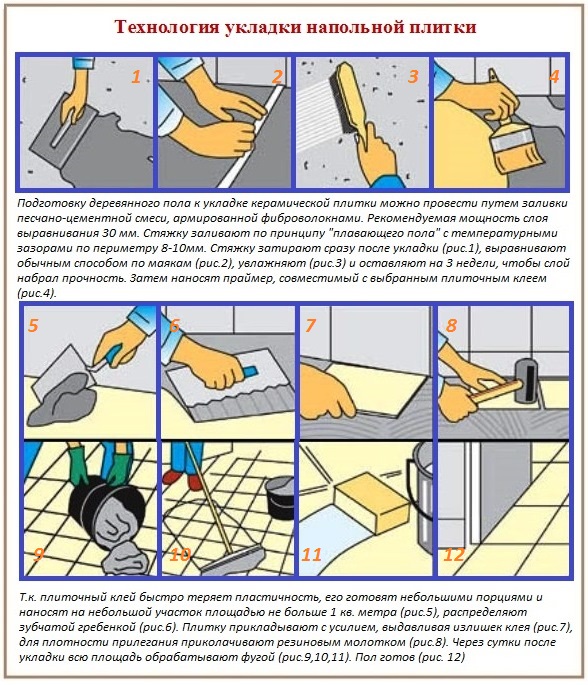

Method Two: Wet Screed

Or a lightweight version of the traditional type of alignment. Filling the screed in an easy-sparing form is required because the load-bearing capacity of the wood floors is not enough for a full leveling layer. There is another specific feature: the screed on wooden floors should be cut off, both from the underlying base and from the walls. Those. it must be arranged according to the type of a floating floor with a deformation gap around the perimeter and around communications crossing the ceiling.

Thanks to the use of the floating scheme, the wooden floor elements will be able to move as much as they like, and ceramics with monolithic preparation will lie motionless.

The standard thickness of the screed, poured onto a wooden floor, is 3 cm. It is undesirable to increase power, because at the same time the weight will increase. Reduce also not worth it, otherwise it will be quite reliable. Minor deviations in both directions are allowed.

The process of pouring screed on a wooden floor in steps:

- We disassemble the floor to the beam for a detailed diagnosis. All wooden components of the floor, causing the slightest doubt in reliability, are dismantled, replaced with analogues. If the step between the lags is more than 50 cm, we strengthen the system by installing an additional beam. A gap of 1 cm should remain between the ends of the lag and the walls of the building. All floor details must be treated with antiseptic impregnations before reassembling.

- We are building flooring for future casting. Old boards with a thickness of 4 cm are suitable if they are suitable for further use. Grooved material does not need to be knit together. Approximately 1 cm should be left between the boards for ventilation. In the same way we do with unedged boards in case of replacement of worn floorboards. If the boards are laid tightly, then in the flooring you will have to drill ventilation holes.

- To the boards across their direction we fasten the quartered moisture-proof plywood at least 12 mm thick or other boards from pressed woodworking waste. Elements are arranged according to the principle of brick laying, fastened with galvanized self-tapping screws after 20 cm. There should not be cross-shaped joints. Between sheets necessarily gaps of approximately 3 mm are left.

- The flooring is covered with waterproofing. It is better to use bitumen or paraffin paper, parchment or glassine. Thick polyethylene is not prohibited. To form a monolithic insulating carpet, we lay the rolled materials with overlaps and fasten with adhesive tape. On the perimeter, you need to create something like bumpers with a min 10 cm approach to the walls. For convenience, we also fasten them with adhesive tape pieces to the walls.

- We lay damping tape along the walls, 0.8-1.0 cm thick, 10 cm wide, we put sleeves on pipes.

- Fill the screed with the factory leveling mixture. or a homemade leveling compound. To prepare it, you will need 2 parts of sifted and washed coarse sand, liquid glass in the same amount. You need to shut the home-made mixture with one part of water without biogenic and technogenic pollution.

As soon as the flooded layer hardens, tile can be laid on a wooden floor with a preparation created on top of it that is independent of overlap.

When carrying out facing works of any premises with the help of tiles, it is necessary to lay not only whole tiles, but also their parts. This raises the question of how to cut tiles so that the edges are smooth. About special tools with which you can do this, we will tell in the material:https://floor.expertexpro.com/en/pol-pokritiya/plitka/kak-rezat-kafel.html.

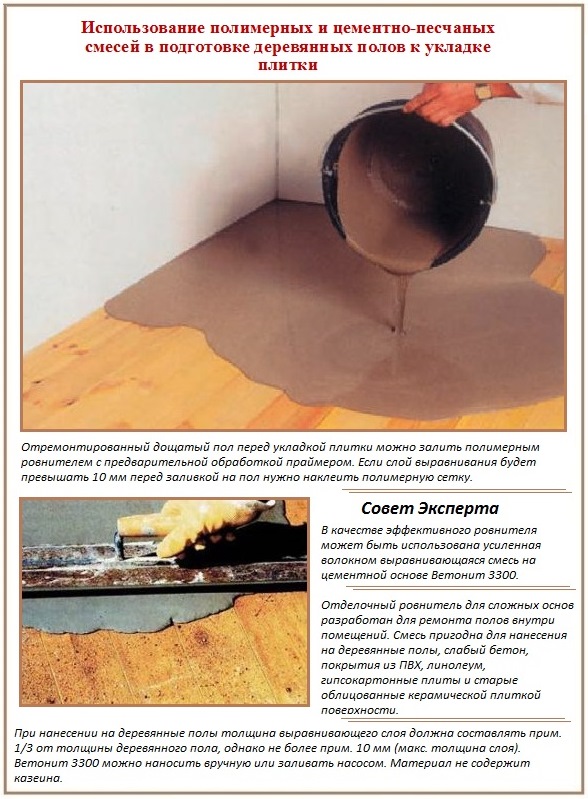

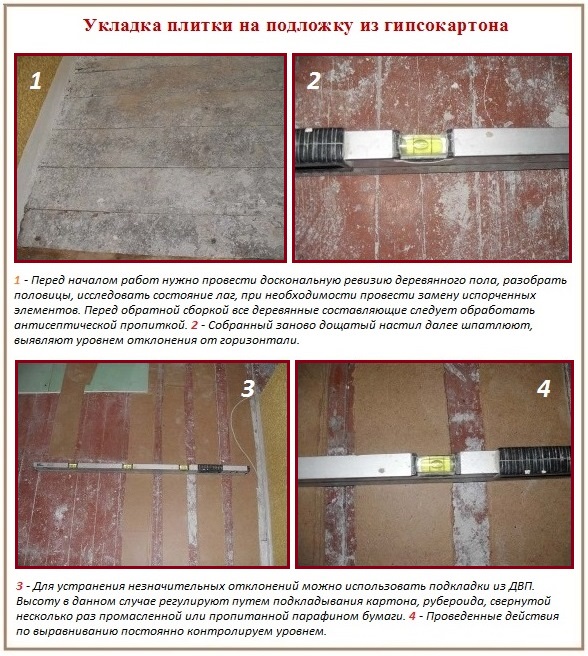

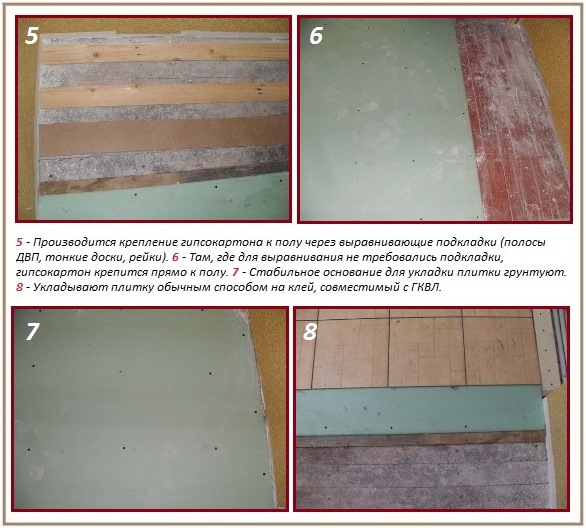

Method Three: Express Option

It consists in fastening sheets of moisture-proof drywall to the plank floor with the help of two-component polyurethane adhesive, the elastic structure of which is not disturbed by the movements of wood.

Previously, the master needs to conduct a design review and repair, if necessary. In order to increase the stiffness of the floor, GKVL can be laid in two layers so that the seams of the upper row do not coincide with the seams of the lower one.

Plasterboard sub-base for tiles It is constructed by analogy with the previous schemes as a floating floor, according to which a technological gap should be left along the perimeter of the room. The joints are filled with sealant, then the entire area is primed with a universal primer.

It is recommended to fill the temperature seam left around the perimeter after laying the flooring and trimming the excess insulation with a sealant and close it with a skirting board on top. This is necessary so that when wet cleaning is performed, water does not leak out, does not accumulate there and does not spoil building materials.

- The subfloor must be waterproofed. To protect against moisture in this case, bitumen waterproofing is best suited. Unlike various polymer films, the water-repellent composition of this type is applied in liquid form and penetrates the upper layers of wood. Thanks to this processing method, it is possible not only to protect the wooden base from various kinds of leaks, but also to prevent the appearance of fungi.

- If glue in the form of a dry mixture will be used for laying tiles, then the gypsum fiber sheets must be saturated with deep penetration soil (for example, Primer No. 6 made by Artisan). Since cement-based adhesives are diluted to the desired consistency with water, we have one negative factor: when introduced into the structure of a gypsum fiber board, moisture changes the linear characteristics of the gypsum fiber - due to the swelling of the material, its dimensions increase, and after liquid evaporation decreases. These movements can lead to cracking of tile joints, and in some cases to damage to ceramic tiles. A thin layer of primer will serve as a barrier that will not allow moisture to be absorbed into the GVL. If you decide to use the finished two-component epoxy-polyurethane composition, then additional processing is not required.

- You can improve the technical characteristics of even the most inexpensive tile adhesives using latex additives, for example, the brand Latexcol –m from the manufacturer Litokol. The plasticizer is suitable for any cement-based compositions and can increase their elasticity, strength and water resistance.

Many questions from our readers concern the arrangement of a warm floor. If you need to mount it on top of a wooden one and close it with ceramic tiles on top, then proceed as follows. GVL is protected by a waterproof film, on top of which a building mesh with a cell of 100 × 100 mm is laid. Underfloor heating pipes are attached to the latter, a wet screed is made with a thickness of at least 3 cm and ceramic tiles are laid. When installing an electric type underfloor heating system, concrete screed can be discarded - in this case, the cable is embedded in the layer of tile adhesive. As for the requirement that the floor in the sanitary facilities should be below the level of other rooms, then in our time it can be considered irrelevant. Using a leak prevention system that automatically shuts off the water supply when wet sensors are placed on the floor, you can reduce the risk of flooding to a minimum.

The three methods of the preparation device given above are just a hint that needs refinement taking into account the technical specifics of the object. Variations on the construction of a kind of fixed "tray" over a freely moving wooden base are much larger. It is important to take into account the principle: a rigid substrate should not destroy the floor and vice versa, the rough floor should not destroy the screed with tiles attached to it.

12 comments