How and how to stick linoleum to the concrete floor: analysis of the technology of work and adhesives

Clay in household for laying linoleum is used infrequently. The need for it arises in the case of active movement of people or movement through the room of large-sized heavy objects. Sticker coating works can be handled without problems if you know how and how to stick linoleum to the concrete floor, what should be done to securely fix the flexible coating.

Content

The specifics of gluing linoleum to concrete

A concrete base is understood to mean all types of base floors in the construction or manufacture of which cement powder was used. Depending on the purpose of the premises, linoleum is laid both on floor slabs with joints pre-filled with mortar and an applied leveling layer, and on numerous types of semi-dry and wet screeds.

The listed base options differ in the percentage of sand, gravel or gravel aggregate. Despite the difference in composition, they all belong to the category of adsorbing rough floors - i.e. capable of absorbing, “pulling” and retaining liquid, gaseous and even solid components of materials adjacent to them.

The adsorption characteristic of concrete floors is an excellent quality if the coating is planned to be laid forever. However, a rare owner of a house or apartment does not want to periodically change the interior, in addition, the most durable brands of commercial linoleum still have the property to wear out. Therefore, gluing technology involves the use of compounds that make it possible to remove material without problems.

At the same time, the adhesive compositions are required to hold the coating firmly during operation. Modifiers should not be "washed out" of linoleum if the latter took place during production. Therefore, gluing should use only those types of glue that a particular manufacturer recommended for fixing a specific brand of their products.

Suitable for bonding to rough concrete floors:

- Linoleums with insulating base. The back of them is equipped with a woven or non-woven substrate that impedes the passage of heat and sound waves.

- Alkyd linoleums. Otherwise, the glyphthalic type of coating. It is made with the basis of a woven or non-woven fabric.

You can stick both household and commercial brands of linoleum. This is more often the case with the latter, because the former may not be fixed at all with glue.

Baseless linoleum grades cannot stick directly to a concrete rough base. For laying them on a concrete floor, a preliminary arrangement of a dry leveling layer of plywood, fiberboard, particleboard and similar materials is required. OSB boards are suitable for use as a dry screed under linoleum, if the thickness of the coating to be laid is more than 4 mm.

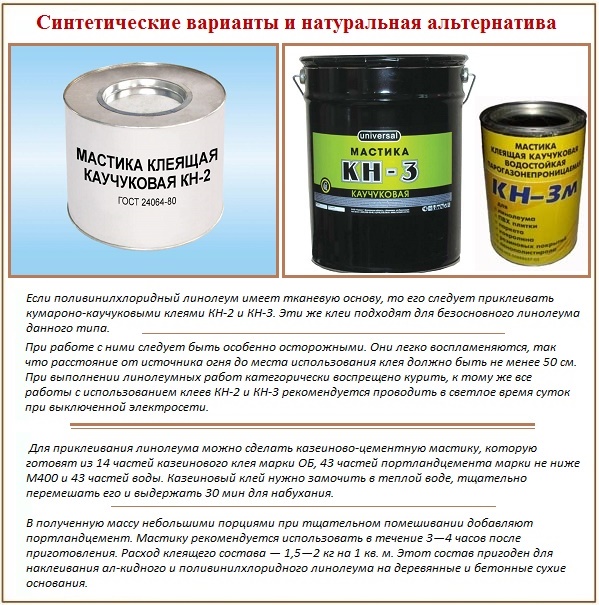

In gluing linoleum are used:

- Dispersion formulations. These include the well-known Bustilat, ADM-K, AK, Gumilaks and their foreign counterparts. They are used for fixing linoleums on insulating substrates and tissue sub-base.Bonding is carried out immediately after applying the dispersion adhesive system with a layer of 6 - 7 mm on a concrete base.

- Bituminous mastics and glues. Among them are “Bisci”, domestic and foreign bitumen-polymer compositions. Used when gluing linoleums with a tissue base. Bonding is carried out after 15 - 20 minutes after application with a layer of 4 - 5 mm.

- Mastics based on synthetic rubbers and resins. These are various variations of oil-chalk, varnish-chalk, bituminous-chalk, casein-cement systems, such as KN-2, KN-3, "Perminid". Used for gluing PVC and alkyd linoleums without substrates. Apply a layer of 3-4 mm.

Mastics, created on the basis of artificial resins and rubbers, are applied to the base and back of the floor with a spatula or even with a brush. Linoleum is not immediately glued to this glue, but after waiting for an “tack” - i.e. spontaneous weathering of excess solvent from the composition applied to the rough floor. Only then with a layer of mastic in 2-3 mm cover the back side of the material, and after 10 - 15 minutes already stick.

The first two of these types of adhesive systems are applied to the rough base with plastic, metal or gear spatulas. The size of the teeth is determined by the required thickness of the applied layer. When applying mastics with a synthetic base, do not use a metal spatula due to the risk of fire and the likelihood of an explosion in contact with metal.

Excess glue that protrudes in the seams after the sticker must be removed immediately with a rag. Mastics that have fallen on hands are removed with a suitable solvent, dispersion adhesives can easily be washed off with water.

Depending on the dimensions of the room, gluing is carried out over the entire area, around the perimeter or only at the butt joints, if any. Joints are glued with Perminid or TGF-70M. In rooms up to 20 m², full gluing is optional. In residential premises, it is generally better to use double-sided tape, placing it exclusively around the perimeter.

Step-by-step gluing technology

If the optimal coating is chosen and in accordance with it it is determined what linoleum should be glued to, you can begin to study the technology and the subsequent production of works. Let's consider two main methods, according to which household and commercial brands of linoleums are fixed on the concrete floor.

Conditions for the performance of work

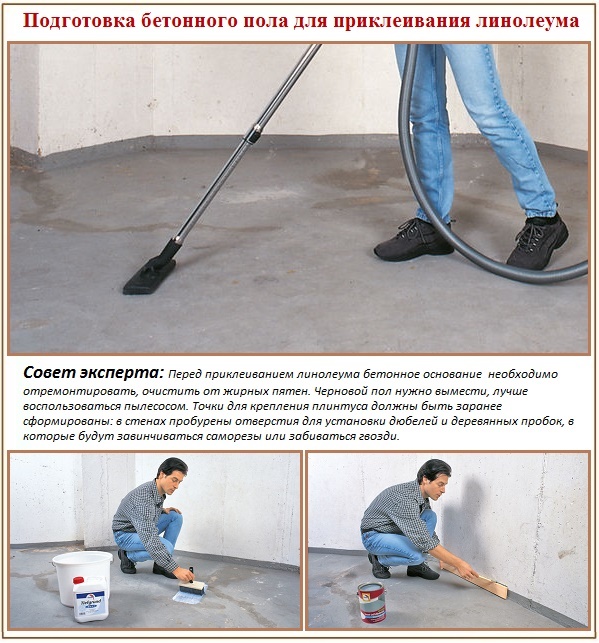

We will take into account that the base before gluing must be carefully prepared, repaired if necessary. Under the two-meter rule or building level, applied to the rough basis in all directions, there should be no gaps greater than 2 mm. Skirting should be removed. The floor should be thoroughly swept out, if necessary, vacuumed, thoroughly dried.

If gluing is planned with KN-2 or KN-3 compounds, the maximum humidity of the leveling concrete screed should be no more than 4%. Its optimal value for the application of all the other listed systems is 5%. However, when using bituminous mastics, a subfloor humidity of 10% is allowed, although it is recommended to dry it better.

The temperature in the finished room should not be lower than 15ºС. In addition, the material needs to "get used" to the environment. Adaptation will require a minimum of a couple of days, during which the coating is simply in the room. Adapting to upcoming operating conditions, the rolls do not roll.

Mandatory preparatory phase

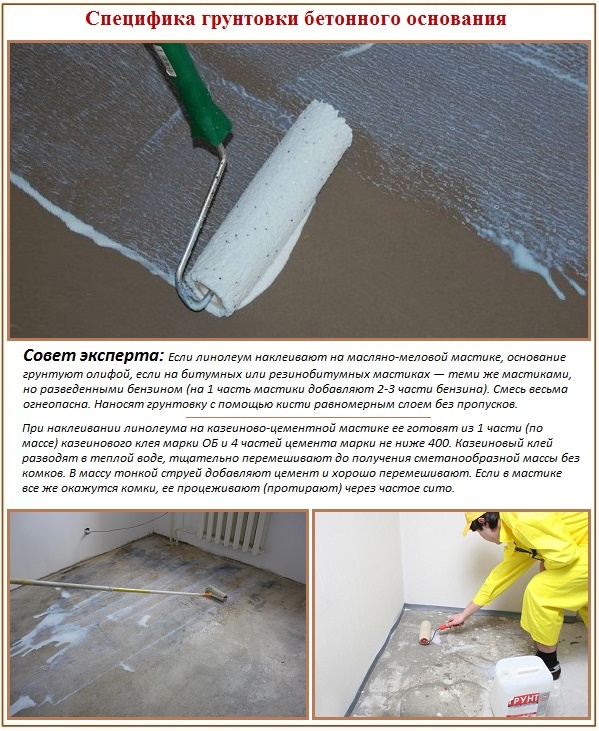

Before the sticker, the concrete floor must be covered with a primer, the composition of which is suitable for use in combination with the selected adhesive. Compatibility is usually specified by the manufacturer. If the coating will be glued to bitumen and bitumen-polymer mastics, then the primer can be primed with the same mastic diluted with gasoline in a ratio of 1: 2 or 1: 3. The first digit indicates the proportion of the mastic.

When applying adhesives with a synthetic base, priming is carried out with drying oil.

In general, there is an opinion that the back side of linoleum should also be covered with soil. To do this, he is first cut up and laid out in an inverted position in an adjacent room. However, it is not always possible to carry out such a primer, because in most cases only the subfloor is primed.

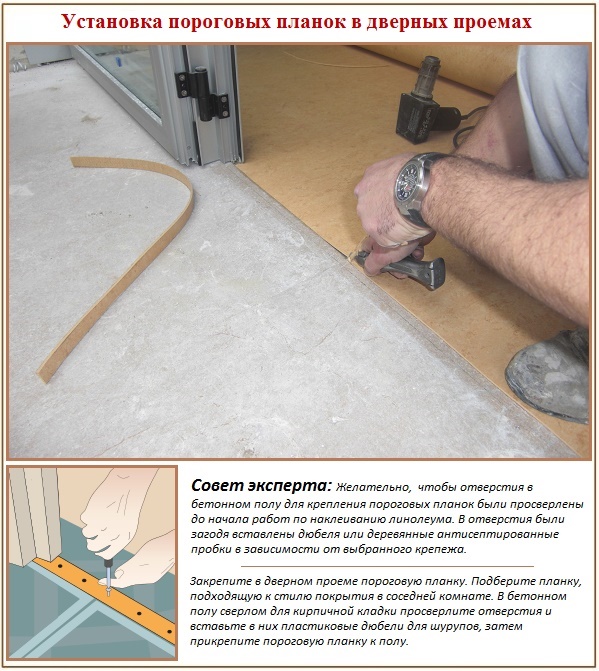

Before starting work, i.e. even before preparing the concrete floor, you should drill holes in the walls for installing the baseboard. The height of the baseboard must be calculated ahead of time. It should not press linoleum, but only touch its surface. We equip the holes with dowels or wooden plugs, depending on the fasteners used. Similarly, the points of fastening of the thresholds of the sills in the floor are formed.

Instruction on gluing household linoleum

Linoleum in the household category is usually laid with a single sheet. The width of the material is 4 - 5 m, which allows us not to strain in our apartment realities with cutting, fitting and installation of seams. Cutting of the whole web is carried out exclusively around the perimeter. Moreover, you don’t have to worry about the quality and evenness of the cut, all the flaws will be hidden at the end of the work with the baseboard.

Household linoleum is not so tough and fragile as its commercial counterpart, therefore, in the layout and folding / unfolding it does not require close attention and accuracy. But it serves less than commercial options, whose fragility is explained by their enhanced resistance to abrasion.

Despite the flexibility and ability to quickly level out, household linoleums still need to give time to lie down before the sticker. With wave, they say goodbye faster than commercial counterparts.

However, until the material becomes perfectly even, one should not proceed with fixing to glue. If the panel significantly exceeds the size of the floor, it must be cut, leaving approximately 5 cm on each side.

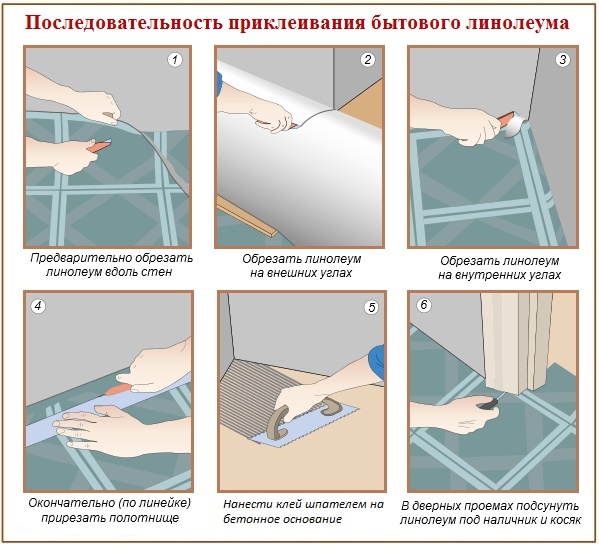

The algorithm for cutting household linoleum:

- We roll and lay the linoleum panel so that its edges go into the walls of the room by about 5 cm.

- We remove the accumulation of air under the coating - we “expel” them with a brush, acting from the center to the periphery. You can do all this with your feet shod in felt boots. Then forget about the coating until it goes wrong.

- After making sure that the waves disappear, we proceed to pruning linoleum. Press the coating with a metal ruler along the line connecting the wall with the floor, cut it strictly according to the ruler. Note that between the wall and the edge of the canvas there should be a gap of about 0.5 cm, a maximum of 1 cm.

- We carry out cutting of external corners. To do this, bend the canvas with the inner side up. We put scraps of boards or fiberboard under the hem so as not to damage the part of the coating lying on the floor. 5 cm from the corner we make an incision on the bent part and finally cut it.

- We cut the inner corners. Here, first we add the edge of the banner in the form of the letter V. We cut the fold into two parts in the center, then we impose the cut edges on top of each other and cut along the line of the corner.

The material around the pipe penetration and in the doorway is first cut with a certain margin. They will need to be carefully cut after the final fixation of linoleum.

After cutting, we again forget about the coating for a couple of days, so that the waves formed by the roll-up format of delivery will straighten out. In addition, the material must take a stable shape: it will stretch slightly or sit down. At this time, we recall or find out with what kind of glue we can glue linoleum to the concrete floor, and purchase it according to the flow rate specified by the manufacturer.

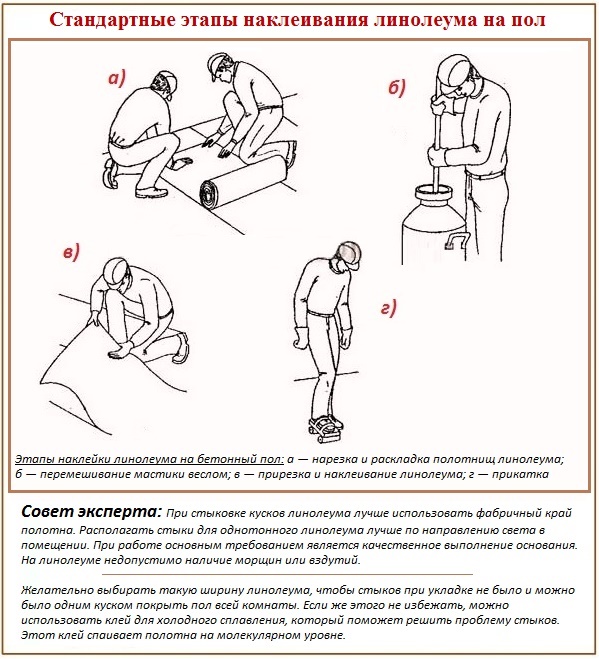

After the required technological break, we proceed to gluing:

- Bend half of the sedimented linoleum.

- We apply a notched trowel to the concrete base and evenly distribute the adhesive composition. In small rooms it can be applied in the form of a grid or only along the edge of the panel.

- We return the half of the coating back either immediately if we use dispersion glue, or we wait for the period set by the technology if products with a bitumen or synthetic base were used.

- Smooth the coating until the glue has set. For smoothing, it is advisable to stock up on a construction roller, a large similarity to a rolling pin or similar device. We carefully and methodically drive out accumulations of air from under the linoleum, moving from the middle of the room to the periphery.

- We do the same with the second part of the banner.

The edge of the coating must be brought under the door jamb. The platband for this will have to be slightly filed. In the area of the doorway, it is desirable that the material runs in the center.

If two panels need to be fixed on the floor in a large room, then both parts of the coating are glued according to the described scheme. The difference is that under the edges of the sides to be joined, the glue is not applied in strips. The width of the “dry” strips is approximately 10-15 cm. And linoleum panels with an overlap of 2-3 cm are laid.

The junction line needs to be thought out during the cutting period. The canvases must be spread out and cut so that along the butt line there are factory edges. Those. first one strip is cut out in fact, then the roll is turned over and directed in the opposite direction. It should be borne in mind that the coating with a pattern when performing work according to such a scheme, must be carefully combined so that there is no inconsistency in the ornament.

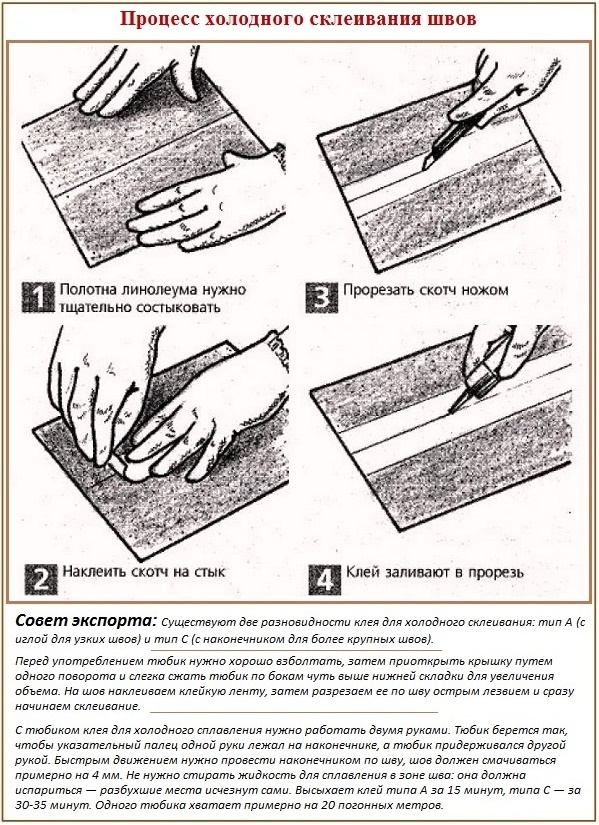

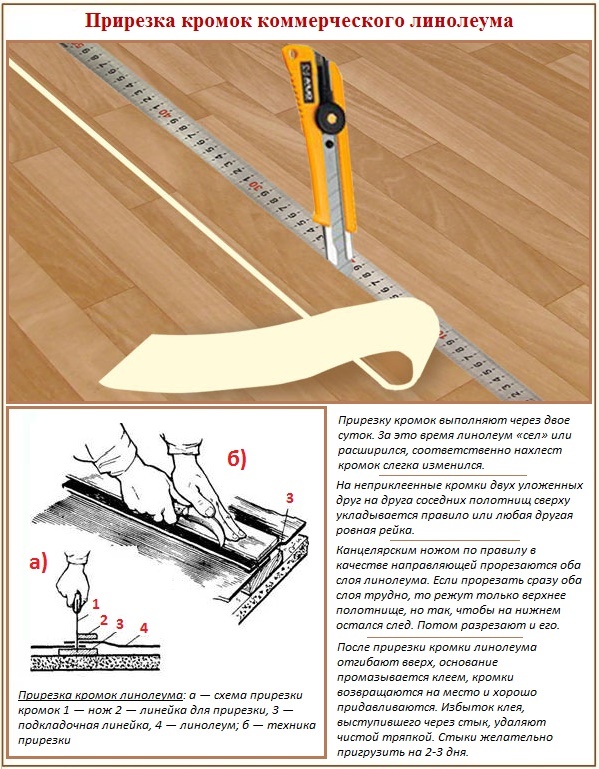

Two, even better three days after gluing the panels, the elastic coating took on a relatively stable size. Relative, because during operation from temperature extremes, linoleum will still stretch and contract somewhat. However, you can already start jointing without fear.

Given the combination of ornament, we apply a rule or a metal ruler to the line of the upcoming cut. It is necessary to cut two layers at once. After we remove the trim, we will bend the non-glued edges of the panels. Again we apply the same glue by the same method that glued the main array of linoleum.

We glue the edges, press, to expel the air, remove the excess glue that protrudes in the seam. Then we roll the joint with a roller, press down with a board or a similar load and forget about it for another 2 days. At the end we fix the baseboard. In the doorway, set the threshold bar. All.

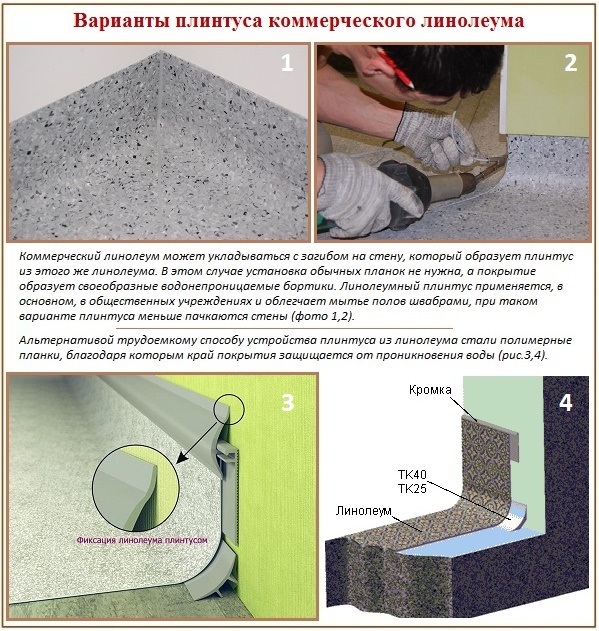

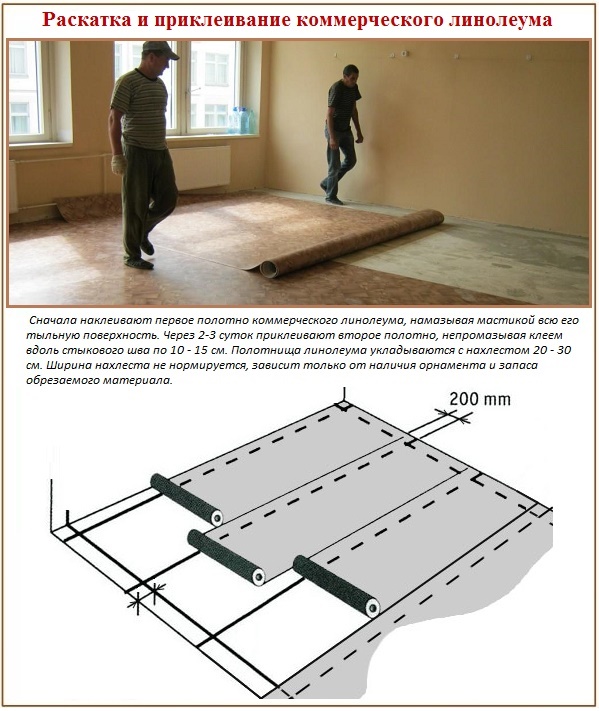

Guide to commercial linoleum

The standard width of commercial brands is 2 m plus / minus 10 - 20 cm. It can be laid without joints only on the floor of narrow covered terraces, corridors or small rooms. A solid plus, that you do not need to combine the drawing when cutting, because The design of most options is simple and unmarked. The color is sustained in the same tone or resembles a concrete floor with marble chips.

Handle while working with commercial linoleum should be extremely careful. It is brittle: it cannot be folded tightly, loaded when folded. Do not bend too much, forming an overlap on the wall. Roll-up for glue processing of the floor is possible only in a roll of large diameter. Flex the material carefully so as not to damage it.

In general, gluing works are carried out in the same order that is used for fixing two linoleum linens. However, there are specific rules for cutting and gluing commercial linoleum.

Commercial linoleum options:

- They are considered non-shrink, therefore there is no need to leave a technological gap between the walls and the coating.

- They can be cut with approaching the walls in the form of original skirting boards or strictly along the line of joining the floor with the wall.

- When replacing the floor during repair, cutting along the edge of the baseboard is allowed if it is not planned to replace it.

- The air from under the newly adhered coating is squeezed out with a piece of particleboard or similar material wrapped in several layers of soft cloth. By analogy with the household option, rollers and own legs in felt boots can be used in this case.

- Rolls rolled up to half are laid on the floor treated with glue, rolling out gradually with simultaneous expulsion of air.

Butt welding is also no different from the previous methods. But cutting two layers at once is optional. If they are too thick, it is permissible to cut through the upper edge, then the bottom. After cutting, the edges of the panels are also bent, the base is glued and the material returned to its place is fixed. If the seam diverges in places, correct the situation by welding.

Video Tips for DIY Finishers

The video will help you understand how to properly stick linoleum to the concrete floor: the video clearly shows the process:

The work of gluing linoleum can not be called easy, but there are no special difficulties in the technology. For its implementation do not need the skills of a finisher. If you follow the rules, the floor will be perfect.

2 comments