How to glue linoleum: a comparative review of adhesive compositions

All linoleum can be divided into two large groups. In one of them are natural floor coverings, which are based on natural components. It can be processed linseed oil, resins, wood flour and other similar components. In another group, PVC coatings are available, which are made from polyvinyl chloride and many different additives that affect the functionality of the material. Naturally, synthetic linoleum is cheaper than natural coating. Glue for linoleum is selected based on which group of materials it belongs to. Information on this can be found on the packaging of the adhesive mixture, which the official manufacturer must place. Ignoring these recommendations may adversely affect the decorative qualities of the material, as well as the degree of its adhesion to the base.

Types of adhesives for PVC coatings

PVC coatings can be laid in two ways, which differ only in the volume of the glued surface of the material. In other words, we can say that linoleum can be glued with a continuous sheet, but only the edges of individual strips along the perimeter can be fixed.

For each option, manufacturers produce different types of glue, which, differing in their composition, have different performance characteristics. There are universal tools that you can also use:

- Water based dispersion glue is used only on substrates whose surfaces can absorb water. This adhesive can be applied on a self-leveling screed, as well as on a concrete or wooden base. The PVC coating does not absorb water, so sticking new linoleum to the old similar coating does not work with water-dispersive glue. The adhesive solution is applied only to the base.

- A special contact adhesive can cope with this task, which allows gluing linoleum to any base. This composition does not lose its adhesive properties after drying. Apply this glue to both glued surfaces. Within a certain time specified in the instructions, the glue is dried. Then the surfaces treated with glue are pressed tightly against each other. The gluing procedure takes several seconds, despite even the presence of creases or bends on the linoleum canvas.

Important! See the consumption of glue for linoleum on the packaging.

Glue for natural linoleum

Having dealt with synthetic coatings, let's find out what glue to glue linoleum made on a natural basis. For laying natural linoleum related to expensive types of flooring, special glue is produced. The main feature of its composition is the minimum amount of water, which can affect the modification of the properties of the natural coating. This material is sensitive to moisture, under the influence of which it begins to deform. To level the processes of deformation, a strongly fixing glue is used for the joints of linoleum, which is able to provide rigid adhesion.

Important! In no case should you use glue for PVC coatings when sticking natural linoleum.

How to connect linoleum canvases?

In small rooms there are no problems with finishing joints, since linoleum is glued with one strip of the desired width.If you have to work with individual canvases, then you need to take care of the reliability of their fastening in the place of contact. Indeed, during operation, linoleum in these places may begin to exfoliate and swell. Moreover, it is not only ugly, but also unsafe.

Commercial linoleum is connected using hot welding, which is carried out by special compact equipment. It is desirable to connect a soft household coating using cold welding, which is a regular tube with special glue.

Hot welding

Hot weld processing is carried out after linoleum sheets adhered to the base. To perform this operation, you will need a cord, as well as a special tool that can heat up to 400 degrees. At the junction of the paintings, a groove for the cord is first cut through. Then it is inserted into the welding gun, which allows you to quickly insert the cord into the previously made groove. Under the influence of high temperature, the cord melts and connects linoleum webs to each other. After that, the surplus is cut off from the still hot seam with a special knife. When the seam cools down, it is polished. With the help of cords of different colors, you can add a twist to the design of the room.

Cold welding

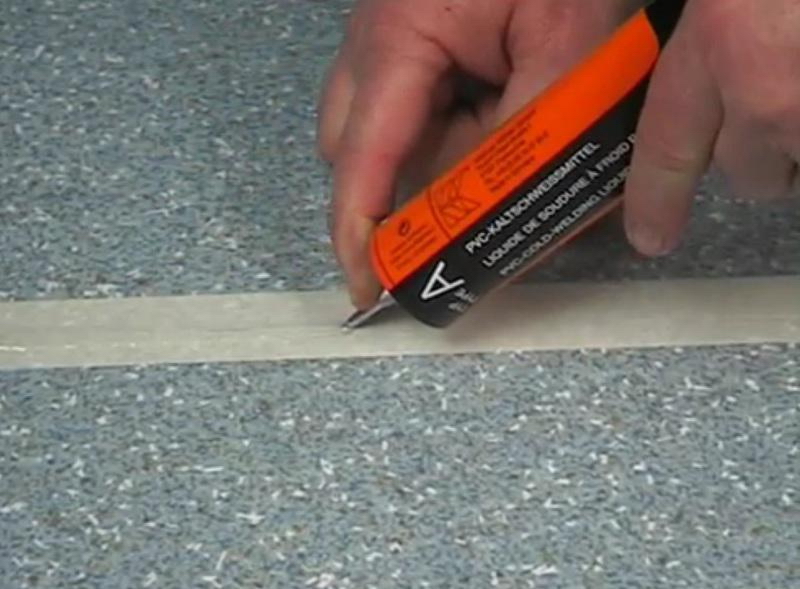

Cold welding is easy to do with your own hands, as it does not require any professional equipment. Glue for cold welding of linoleum is available in two types. For the newly laid strips of new linoleum, you need to buy glue A. If it is necessary to glue the joint in the old coating, which has been used for a long time, then choose glue C. Moreover, when working with more liquid glue A, the sheets are pre-glued with tape. Then an incision is made in it and glue is poured there. Ten minutes later, the adhesive tape is removed along with the adhesive mixture that has fallen on it. There remains a neat seam that you can walk on.

In custody

We hope that this material will help you understand the intricacies of choosing the right glue. Experts recommend buying glue and linoleum at the same time so that the seller can advise the best option for the chosen coating.

2 comments