Features of laying a laminate on a concrete floor: advice from the masters

Laminate is the “youngest” type of flooring currently existing on the market. Due to its not too high price, aesthetics and practicality, it has become for many the best option. Moreover, it can be laid on a different surface, for example, laying a laminate on a concrete floor is a fairly common procedure and is relatively simple to do it yourself.

Content

What laminate flooring is suitable for us?

In appearance, the laminate resembles a thin board. Thickness can vary from 7 to 12 mm, and width - from 17 to 30 cm, length most often 1 - 1.5 m. In structure, it looks like a multi-layer cake. Each layer performs its specific function:

- stabilizing;

- main;

- protective;

- decorative.

Depending on the method and production method, a direct pressure laminate and a more modern high pressure laminate are distinguished.

The service life of this coating, unless force majeure occurs such as a local flood or fire, depends mainly on the top layer of the protective film. In a high pressure laminate, this component is multicomponent. In addition to expensive acrylic or melamine resins, corundum or alumina is used, which significantly increases strength. The protective film serves to protect the material from abrasion, exposure to chemicals, ultraviolet rays.

Under this transparent protection is a decorative layer. This can be paper or a special foil with an image printed on it. It depends on him how much the coating will be aesthetically pleasing and beautiful. Most often, the pattern imitates different types of wood, as it is more familiar, but there are collections with a pattern of stone, metal and even carpet.

Below is a carrier layer made of high density fiberboard (HDF) with moisture resistant impregnation. He is responsible for the strength of the product, there is also a lock designed to connect the laminate.

In products that are manufactured according to the latest technologies, there is also a stabilizing layer. It protects the overlying layers from moisture and has soundproofing properties. Direct pressure laminate is simpler, has a 3-layer structure. Connect all layers by compression, at high temperature.

You will learn about how to choose a good laminate and what to look for when buying material from our special article:https://floor.expertexpro.com/en/pol-pokritiya/laminat/kak-vybrat-laminat.html.

Laminate Classes

The most significant parameter that you pay attention to when choosing a laminate is its wear resistance. It is determined using a special test, the results of which are divided into classes. The laminate class is written in two digits.

The first indicates the type of premises in which you can lay the floor: "2" - for individual use, "3" - for public use. The second digit indicates the permissible floor load intensity. The larger it is, the higher the load is allowed.

- 21 - “home” laminate, suitable for rooms with low load (children’s, bedroom),

- 22 - “home” laminate, which is suitable for rooms with an average load (kitchen, dining room),

- 23 - “home” laminate for rooms through which a large number of people often pass,

- 31 - "commercial" laminate is suitable for rooms with low intensity of visits (office),

- 32 - "commercial" laminate, which will be appropriate in the rooms with a load on the floor surface close to average (reception room, for example),

- 33 - "commercial" laminate for a room with a high intensity load on the floor (store).

Laminate Types

There are several ways to connect panels. Depending on them, there are three categories of laminate: adhesive, "Click", "Lock".

Now the adhesive joint is practically not used because of its complexity and impracticality. As a result of its use, a continuous coating was obtained, which could not be dismantled if necessary, and this is not always convenient.

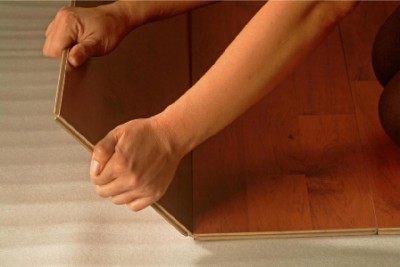

“Click” or “double lock” is a more complex and fairly reliable connection system. It allows you to assemble-disassemble panels many times without damaging them. For assembly, it is necessary to bring the next panel to the previous one at an angle of 30 degrees and connect. When the panel is rotated to a horizontal position, it clicks into place. This type of joint is the most popular right now, because it makes it easy to lay laminate even to lay people.

A laminate equipped with a Lock system is cheaper because the strength of the joints is lower. It snaps into place when the next panel is carefully “driven” into the horizontal position into the previous one, with frequent assembly-disassembly, it is likely to damage the lock parts. Requires careful handling during installation.

Concrete foundation preparation

How successful and quality will be laminate flooring on a concrete floor is largely dependent on the condition of the base. The finished surface for the installation of a new floor covering (in this case, the laminate) must be strictly horizontal, even, protected from moisture, have good thermal insulation and sound insulation.

It happens that it is not possible to achieve a perfectly even base and there are small differences. Let's talk about how to lay a laminate on an uneven floor and compensate for defects in the material:https://floor.expertexpro.com/en/pol-pokritiya/laminat/ukladka-laminata-na-nerovnyj-pol.html.

If old floors were previously dismantled, then the surface must be leveled. The differences in the height of the base should not exceed 2 mm per square meter of surface. If they are more significant, then you can try to eliminate them in simple ways: by filling the pits or knocking down the ledges. If this is not possible, then it is worth resorting to arranging a new floor screed.

Suitable as a traditional concrete or cement screed, which, however, requires long-term drying, as well as more modern options, for example, bulk quick-hardening mixtures. The thickness of such coatings can be very significant. They dry out quite quickly. Many manufacturers claim that within a few hours after pouring, you can walk on such floors. Do not flatter yourself and rush. It can and can be walked, but there is no need to rush to lay the laminate. The complete drying of such surfaces takes several days.

Next, you need to lay waterproofing. As the cheapest option, but not the best, let's be honest, an ordinary film is suitable, overlapped and connected with adhesive tape.It is preferable to use special substrates made of extruded polystyrene foam or polyethylene foam, which also have sound-absorbing properties. Even more effective, respectively more expensive, bitumen-cellulose substrate, which includes cork chips. When choosing this option, it is worth remembering that it is not compatible with warm floors and requires special “breathing” skirting boards. Convenient polymer substrates, which have a self-adhesive base, it is quite simple to lay them. You can do without a substrate only in the case of laying a four-layer laminate, since its lower layer performs the same functions, but in this case it is better not to save, but to lay a waterproofing material.

Features of styling technology

First of all, it is necessary to place the laminate in the room in which it will be laid (at least 2 days) before the installation process. This will allow him to “acclimatize” and save him from various problems in the future. Since when laying a surface is formed that does not adhere to the base, gaps must be left near all vertical surfaces of at least 10 mm.

Putting a laminate is recommended with the long side along the luminous flux. After the wedges are installed, to ensure the appropriate clearance, lay the first row of tongues to the wall surface. Finishing the row, determine the length of the last piece, taking into account the gap. The remainder is used at the beginning of the next row, if it is not less than 30 cm, otherwise you will have to cut a new panel. This approach minimizes waste generation and ensures joint displacement, which is important. The last row, if necessary, is cut in width. In this way, a beautiful, even surface is obtained with a minimum of waste from building materials, which cannot but please the zealous owner.

In some cases, laying diagonally may be a good way to install the laminate. Read about the technology of this installation method here:https://floor.expertexpro.com/en/pol-pokritiya/laminat/ukladka-laminata-po-diagonali.html.

Summing up, we can formulate several simple rules for laying a laminate on a concrete base, which will allow you to perform this procedure qualitatively:

- Prerequisite: the base must be completely hardened, dry, clean.

- Instead of repairing the old concrete floor using the patchwork method, it is better to pour new floors or make a new screed. This will protect against elevation.

- A plastic film or other suitable material must be used as a hydro and vapor barrier layer. The overlap between their individual strips should be approximately 10 cm, joints are recommended to be connected with adhesive tape.

As insurance against the occurrence of possible dampness (for example, when laying a laminate on a "warm" concrete floor, heated by circulating hot water), a special substrate is used.

It is unacceptable to lay the laminate if the concrete base "sweats" or if there are mold spots on it. It is necessary to wait for complete drying, make sure that there is no excessive humidity and only after that proceed with installation.

Compliance with these simple rules and accuracy when performing all stages of work will allow you to get a good result. Your floor will delight you not only with its beautiful appearance, but also with excellent performance and ease of maintenance.

2 comments