Wooden mosaic on the floor: add exclusivity to interior design

In the 21st century, exclusivity in interior design has become more fashionable than ever. Just half a century ago, everyone wanted “the same closet as the neighbors” and “the same kitchen as the boss”, and something new and unusual in their own house was condemned. And the stories that “one man stole epoxy varnish at his factory and made beautiful floors at home, and died two weeks later” became especially instructive parables. But as soon as humanity crossed the line of the new millennium, the most beautiful and stylish things became those that are nowhere else.

And it was no longer so fashionable to lay an expensive noble parquet, and the laminate of unusual colors became quite ordinary. And even with 3D technologies in the form of living dolphins in the bathroom, it’s hard to surprise - because the drawing, in view of its complexity, is still taken standard (by the way, in an article about such floors we reveal the secret of how to make such a miracle from any image). But something unusual, preferably made by yourself, is at the height of fashion.

And especially now, wooden mosaic on the floor is in demand. Aesthetic, practical and not at all usual. And the masters who own such art receive a very decent fee for their work. This is because it is exclusive: no one has this and nobody will repeat this (even if desired, it is too complicated). And it looks very, very beautiful. So, do you dream to master such a skill?

Content

The origins of craftsmanship in wooden mosaic flooring

For the first time, this unusual mosaic originated in Ancient Egypt, as much as 2,000 years BC. It was mainly decorated with furniture, as the tireless modern archaeologists found. Wooden mosaic came to our country in the middle of the 18th century, completely transforming the floors of the palaces of the Russian tsars. The serf masters were even sent abroad so that they could learn this exquisite skill there. And so, after so many centuries, the wooden mosaic is back in fashion.

Today it is with great pleasure that they decorate not so much furniture as floors and walls. A mosaic of thermal wood is great for decorating steam rooms and saunas. And floors that give any room an atmosphere of warmth and coziness are especially beautiful. Moreover, such a fashion easily fits into any modern style: minimalism, eclecticism, fusion ... And for modern Russian baths, floors are a wonderful alternative to boring laminate and boards - such a floor is not afraid of temperature changes, moisture or sun exposure.

In addition, the floor of the wooden mosaic does not slip at all, unlike the tiled counterpart.

Step-by-step analysis of marquetry technology

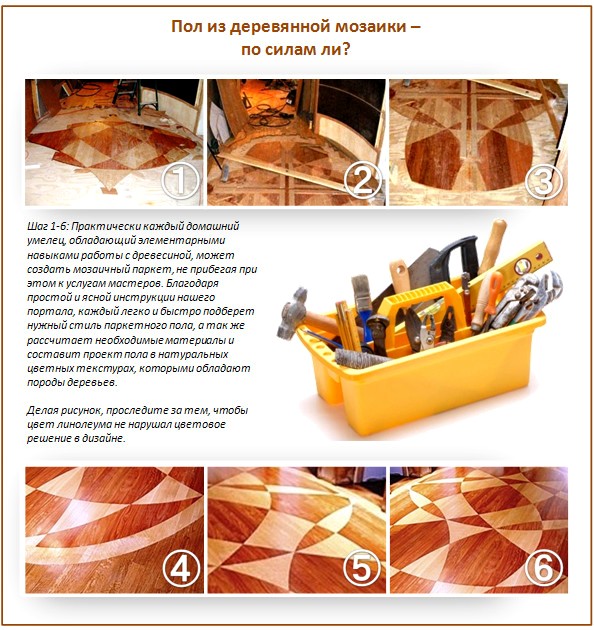

So, responsibly relate to the manufacture of the base - the material on which we will stick the mosaic. It can be bulk floor or ordinary plywood - depending on what is already on the floor.

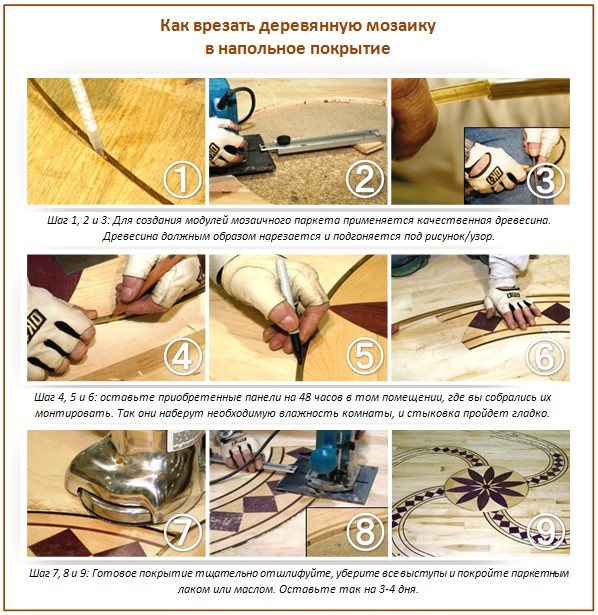

But the technique of creating whole pictures from wooden squares has its name - marquetry:

In fact, the most difficult thing in this whole process is the collection of drawing plates on the workpiece.But cutting chips and stacking ready-made modular elements does not take much time. Usually the question is only in compiling the picture itself - designers usually do not undertake this. But you can easily use the most ordinary program for cross-stitch - it converts any pictures and photos into a scheme of colored squares. And their size can be specially prescribed in advance.

We select wood for mosaic elements

The standard size of wooden chips is 26x26 mm, the thickness for the floor is 15 mm.The best wood for mosaics is a thermo-tree made of ash and oak, other types are also possible, but you need to work with them more carefully. It is possible to make floors from a large-format mosaic, the dimensions of which are 42x42 mm.

For the floor of the bathroom and the bathroom, give preference to waterproof species and thermal wood. Of the exotic breeds, the most beautiful are Kering and Wenge. But in general, in the choice of colors of wooden chips, give preference to these types of wood:

- oak for the main background;

- amaranth for the frame;

- thermal book;

- Kumaru

- lightwood;

- bog oak;

- maple.

Experienced craftsmen combine in one set up to 24 species of wood! By the way, for the decor of individual details of the mosaic floor, you can make spectacular inserts of glass mosaics - in silver or gold.

We collect modular elements

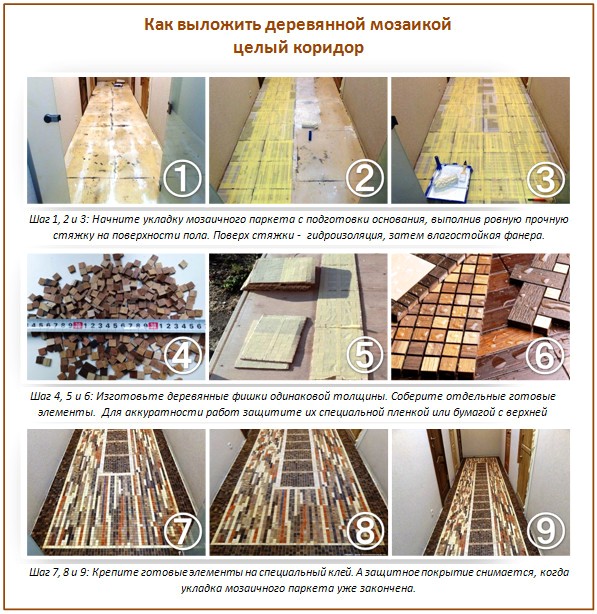

Collect at once not the whole picture, but specific individual square plates with a side of 30 cm. The seam should be only 1 mm.

Glue the chips on the mounting film, on the front side. The seams between small chips need to be wiped - with a 2-component epoxy mixture “Litokol”. This sealant has high elasticity - after all, a tree needs to move as a living material.

Expert advice: if you are preparing a wooden mosaic for the steam room floor, then use not Italian grout (because it has an epoxy base), but Finnish, which is just designed for saunas.

We lay the plates on the floor

You can lay such separate plates “raw” when, after fixing the whole picture, they are sanded and varnished, or in a clean manner, pre-toned and finished. It depends on how much you can work with varnish in the room where the mosaic will be laid, or it is better to prepare everything in advance in the back room.

For a good, even base, take Italian glue VR11 with moisture resistance D3, for problematic or with differences - Bostik mastic.

When you assemble the plate, apply glue to the floor and attach it with the reverse surface to the glue - so that the film remains on the front side. In ten minutes, you need to align and tweak well. In two hours the glue will completely harden and it will be possible to remove the mounting film.

Next, apply varnish or oil, after which - grout, and clean the finished surface with clean water. Take a varnish polyurethane, opaque. And for a special aesthetic effect, you can use glossy - then the surface of the mosaic floor will look like behind glass.

It is very convenient to repair such a surface: knock down damaged chips with a hammer and glue new ones.

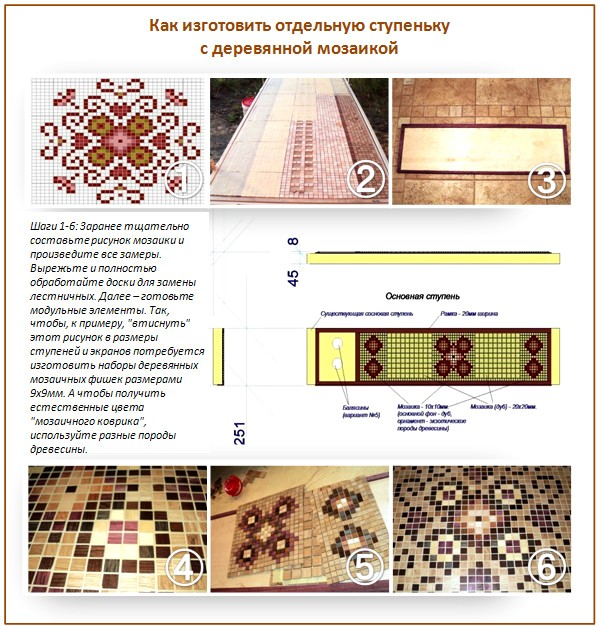

Sometimes, instead of the entire floor, only mosaic borders are made - along the walls, for example. It turns out also great, but today the wooden mosaic in the decoration of the stairs looks especially fashionable:

Work with cork mosaic

And now we will tell you about another type of wooden mosaic - cork. Cork is the bark of a tree. If you have never really delved into what it is so famous for, let’s say briefly: this is unique material. Warm, soft, durable and 100% natural. Such a floor is a salvation for a sick spine, an ideal cover for a bedroom and a nursery, and a wonderful sound insulator.

It’s just that there is a lot of high-quality cork flooring - if you get a cork at all, and not cork chips on glue. But we have great news for you: now you will learn how to make an excellent floor covering from cork mosaic.

Once German designers learned how the number of wine corks is thrown out at the production stage - due to some minor defects. And horrified! Since that time, souvenirs and accessories for the interior of bars and cafes began to be made from this material, and a little later enterprising heads guessed to cut corks into small circles (like sausage) and line them with floors and walls. The coatings were excellent, and the designers themselves emphasized that this use of waste is another good way to protect the environment from debris.

They make cork mosaics also from granulation waste - small triangular chips. This, too, at one time was considered a crime against nature, and they began to make good drawings on the walls and floor from these details.

By the way, even today some manufacturers offer to buy from them a finished cork mosaic, already pasted on panels of various shapes - they just need to be fixed on the floor. Today's leader in the sale of such coatings is the German company Bleile Bodenbelage. They advertise their cork mosaic coatings as aesthetic, fully moisture resistant, soundproof and maintainable.

The cork mosaic floor is very similar to the mint floor, which has become especially popular today. This is done simply: glue the coins to the finished base and fill with varnish. Cork mosaic is somewhat similar to this, only it also has softness when walking and a more natural look. Want to learn how to do this?

Why is such a floor good?

Thus, cork wood is also often called wood species such as Hibiscus tiliaceus, Bombax conyz, Ochroma lagoppus, Pterocarpus suberosus and Aedemone mirabilis. But as an industrial bark, two types of oak are usually used - Western oak (Quercus occidentalis J. Gay) and cork oak (Quercus suber L). All of them have valuable qualities as flooring material.

Cork mosaic itself is today considered a real art. So, the famous artist Saimir Strati created a whole three-dimensional mosaic panel of 300,000 wine corks. It has occupied 95 square meters and will soon be included in the Guinness Book of Records.

Putting a cork mosaic on almost any surface is even uneven, and it’s hard to think of something better for a washing bath, where the floor has a slope to the drain hole. Indeed, modern cork coatings cannot be used in rooms with high humidity - like a bathroom, for example. But cork mosaic - you can, which is its main advantage.

Thanks to its low thermal conductivity, cork always feels warm to the touch - even on cold floors.In addition, cork mosaic has an extremely light weight - on a whole square meter, its mass will be about a kilogram. For comparison: other traditional floor coverings weigh about 20-30 kg per square meter.

And finally, the cork itself is hypoallergenic, which is also important.

By combining a cork of different colors on the floor, you can create a stylish and beautiful mosaic - one that neither parquet nor tile designs can replace!

First steps: we collect material, cut and glue

Collect enough wine corks and carefully cut into the same “coins” of 6 mm. Next, stick them on pieces of paper (conveniently 30x60 cm) and paint the cork in the color you want with dispersion paint or tint varnish. Although some experts believe that you first need to lay the cork mosaic on the floor, and only then paint it - try both options and use the one that is more convenient for you personally.

For convenience, calculate in advance how many total plates you need, and cut off those that will eventually be against the walls.

We fix mosaic plates on the floor

A layer of transparent varnish is applied to the finished cork mosaic on the floor, which will protect the elements from pollution. Now fill the gaps between the circles with a special grout - just pour it on the floor and level it with a rubber pad. It is important to ensure that there are no empty voids anywhere. But remove excess grout with a damp sponge. As soon as the grout dries, wipe the entire floor with a soft cloth and apply a coat of colorless varnish again.

Art Modular Parquet

Some kind of mosaic made of wood can be called art parquet. In it, individual mosaic typesetting slabs are mounted on bitumen mastic and combined according to a special technology:

They begin to lay such parquet from the corner of the room, opposite the front door. For precision, pull the cord and lay the entire facing layer. Between the plates you can optionally place metal gaskets 1-2 mm thick - this will add decorativeness. And so - row by row. Also for gluing parquet mosaic you can use epoxy adhesive EDP or KN-3.

Another quite popular variety of wooden mosaic floors is “medallions”. Such a round element of wooden tiles, beautiful and unusual. For the center of the hall - that’s it.

Spread it out of images of animals, people, the zodiac sign or planet. But to order such floors are expensive to do, but with their own hands - sheer pleasure and many years of joy for the eyes. For the device of the medallion today they often use the Burmese teak. And the seams between the wooden elements are standardly filled with black sealant.

Take your time - the result is worth it!

2 comments