Insulation of the floor with polystyrene foam: analysis of 3 popular situations for insulation

Thermal insulation of the floor is an obvious necessity. It is justified by economic calculations and the desire to provide favorable microclimatic conditions, both in apartments of high-rise buildings, and in autonomous low-rise buildings. Insulation of ceilings will reduce heat loss, eliminate the causes of a number of diseases associated with hypothermia. They increase the thermotechnical characteristics of the walls with the help of different materials and laying schemes, among which floor insulation with expanded polystyrene does not take the last place.

Low values of thermal conductivity of a family of heaters created on the basis of polystyrene substantiate their priorities. Multilayer structures equipped with a foamed or extruded analogue become a reliable barrier to moisture penetration and heat loss. Due to the light weight of materials with a specific structure, there is no need to strengthen floors and foundations. They are used for arranging socles, facades, basements. Universal insulation sheets are mounted both on walls and ceilings. The video demonstrates how the complete arrangement of the loggia using only this type of insulation materials:

By analogy, it is possible to increase the heating performance in garages, warehouse buildings, production shops, at other facilities.

Content

Why is it better to insulate with polystyrene?

There are a number of factors:

- Expanded polystyrene materials are ideal for flooring, as they contribute to the simultaneous solution of two problems: they provide thermal insulation and prevent the penetration of steam and moisture. Steam and waterproofing is especially urgent for homeowners and commercial premises located on the ground floors.

- Polyfoam and its extruded "brother" do not absorb soil moisture, which, being an ideal conductor, significantly reduces the insulating properties.

- A square meter of materials without destroying the structure holds a load of up to 350-400 kg, which significantly exceeds the performance of most finishing floor coverings.

- This type of insulation is compatible with electric and water equipment of "warm floor" systems.

- The structure and geometric parameters of materials do not change either from the swelling of most heat insulation materials, or from prolonged exposure to high temperature.

- Expanded polystyrene is resistant to negative factors of chemical and biological origin.

- Simple not laborious installation. Plates can be cut without problems for the arrangement of small segments, with the help of expanded polystyrene, it is possible to conduct floor insulation in rooms of any area, configuration.

And the main advantage is the affordable price, affordable for most people who want to make repairs or build their own house and conduct effective floor insulation with foam at budget prices.

Note! Materials of the expanded polystyrene class are classified as schemes with the longest possible loyal terms of service to the owners, which, together with the price and lower heating costs, confirms their efficiency.

Types of insulation from this material

Polystyrene heat-insulating materials are divided into two subgroups that differ in the production method, and, therefore, in technical characteristics:

1. Polyfoam. It is obtained by exposure to a blowing agent, followed by sintering of the expanded granules. It is delivered in the format of white plates (gray color options have already been developed) with a pronounced structure of interconnected balls. 98% of the foam mass is occupied by weightless air bubbles enclosed in an impenetrable shell, due to which the material has excellent insulating properties combined with light weight.

2. Extruded insulation is obtained by foaming with gas (CO2), after which the mass under pressure passes through the head of the extruder forming the material. In the context of the frozen mass of green, pink, blue, yellow, it resembles a sponge with small cells and pores filled with air. Extrusion material is ahead of polystyrene both in terms of strength characteristics and prices.

An alternative to foreign products, the price of which includes not only production, but also customs and transportation costs, became products with the Penoplex brand. With technical specifications that are equivalent to Western products, the thermal insulation material is significantly inferior to them in cost, which argues that floor insulation with foam is more convincing than any loud advertisement. Laying on the floor of this heat insulator with almost zero moisture absorption does not require accompaniment as a layer of waterproofing, which can be regarded as an additional pleasant bonus.

Features of insulation of various designs

The material is supplied in the form of slabs 0.6 × 1.2, as well as 0.5 × 1.0 meters; most construction stores offer cutting services.

For the arrangement of living rooms use products marked PSB-S-35, for the insulation of hangars and garages PSB-S-50. In order to increase the convenience of laying, plates with milled edges are produced, they are joined according to the "groove in the comb" scheme.

Important. Upon contact of the foam with organic solvents (mastics, resins), the insulation melts. Direct contact of the material with polymer-bitumen mastics is not allowed. It is necessary to isolate the foam, equipping both surfaces with a layer of plastic film.

Insulation of the floor structure with lags

If the cut foam sheets are stacked between the logs, then PSB-S 15 is quite suitable as a heater, because the main load will be taken by the logs. The power standard for thermal insulation of the first floors is 10 cm, an increase is possible. For floors, 5 cm is enough.

Note. Fill the gaps between the foam and logs, as well as the technological gap along the walls along the perimeter, with Ursa fiberglass insulation. It is cheaper than polyurethane foam.

Thermal insulation with polystyrene foam on a concrete base

In order to conduct insulation of the concrete floor with foam, materials with high strength qualities (PSB-S 35 and others) are selected. Coarse alignment is permissible to carry out with plates of different power, but it is better to make a screed before installing the floor. Then the layers of the floor structure are stacked in the following order:

- waterproofing film;

- foam (foam);

- reinforcing mesh with preliminary application of 2 cm of fixing solution (any of the materials used for screed);

- finishing screed from 5 to 8 cm;

- sealing technological gaps along the perimeter with mounting foam or fiberglass.

Important. Rolled waterproofing overlap in the adjacent lane. It is desirable that the peculiar “span” is 10 cm. Separate strips are fastened with adhesive tape.

Next, as usual: flooring, if necessary, its decoration and baseboard.

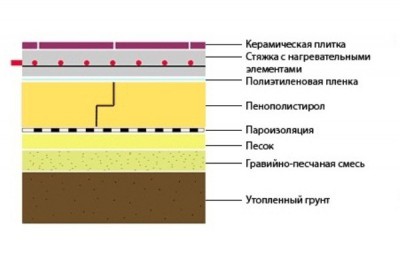

The scheme of insulation of floors laid on the ground

In fact, it differs from the arrangement of the floor on a concrete draft basis only in the preparation of the soil and the laying of layers preceding the installation of insulation:

- The base soil is leveled, then compacted with a tamper.

- A layer of crushed stone with a thickness of 10 cm falls asleep, it also needs to be leveled and compacted.

- Then the sand is fine fraction (marine, river, quarry), it is necessary to fill the voids between the particles of crushed stone.

- This is followed by floor insulation. Styrofoam is suitable as a cheaper option, but the difference will not be so great if you use foam.

Among the insulation made of polystyrene, there are not only materials produced in the form of plates and sheets. It is possible to isolate the floor from heat loss by foaming the material directly on the object or by filling in granules not soldered together, reminiscent of fine gravel.

In custody

Materials for the production of which the starting material is polystyrene do an excellent job. With their help, the floor can be insulated by a performer without experience in decoration and construction. An inexpensive, but effective way of arrangement will help to significantly increase the thermal performance.

4 comments