The choice of sealant for the laminate and how to use it

Laminated board or laminate is a popular and sought-after finishing material, which has earned increased attention to the affordable cost and the outward resemblance to natural wood of various species. A correctly selected and correctly used sealant for a laminate is an important component that allows you to get a high-quality, attractive, reliable and durable floor covering.

Content

Composition and characteristics

Modern resin and varnish compositions create a protective layer, but even the highest quality laminated board is not able to provide one hundred percent protection from moisture in the structure of the floor covering and its castle system. Excess moisture results in deformations of the laminate, therefore sealants that are immune to moisture serve as reliable protection for the most vulnerable areas.

The main characteristics of the sealant used in the process laying laminated boards, due to its composition:

- silicone components provide high performance, as well as decent physical qualities and optimal technical performance;

- compositions of the polymer type have elasticity and strength after solidification, as well as durable and not subject to negative external influences;

- regardless of composition, modern sealants for a laminate are able to withstand temperature extremes and significant moisture loads;

- high-quality compounds are perfect for sealing gaps, crevices and docking areas, providing reliable protection against penetration of water;

- sealants are applied independently and do not require the involvement of qualified craftsmen or specialists in the field of flooring.

The use of a specialized sealant for a laminate prevents gluing of boards during application, therefore it is allowed to carry out local repairs if necessary, dismantling damaged elements.

The components of modern and high-quality sealants are represented by components that are safe for people and the environment, which do not react and do not emit toxins during heating, cooling and under the influence of moisture, organics or chemical compounds. Significant deficiencies are missing completely.

Choosing a good laminate is not easy. Why just go through all the options, evaluate the disadvantages and advantages of each and, finally, dwell on one thing! We will tell you what to pay attention to when buying and help to understand this issue here:https://floor.expertexpro.com/en/pol-pokritiya/laminat/kak-vybrat-laminat.html.

Views

For laying and reliable sealing of a modern laminated board, three options are used, represented by silicone and acrylic, as well as special colored sealants.

Silicone

The composition of such sealants is based on silicone - an organosilicon chemical substance that has excellent technical characteristics.The advantages of silicone products are represented by high elasticity and excellent adhesion, durability and guaranteed safety. The material does not stain during operation, is resistant to temperature extremes and is extremely easy to apply.

The peculiarity of silicone compounds is the impossibility of coloring, therefore, for laying it is recommended to purchase colorless sealants or those already made in a certain color scheme.

Acrylic

The composition of such sealants is based on acrylic - a synthetic polymer that forms very durable compounds, masking small defects on the coating, not cracking and not yellowing during the entire period of operation. The advantages of acrylic compositions include affordable cost and elasticity, the ability to use in the repair of chips and cracks on the floor.

It should be noted that acrylic sealants are extremely rarely produced in a colorless form and incorporate dyes. It is for this reason, when choosing acrylic sealant by color, it is necessary to focus on the appearance of the sample of the stacked laminated board.

Which laminate sealant to choose - popular brands

In the conditions of the modern market of polymer compositions used for processing floor laminated panels, acrylic and silicone sealants are presented in a very wide variety. There are several well-established and popular brands among consumers that produce products based on antiseptic additives that prevent the spread of mold and fungi, quartz flour or chalk, pigments and organic extenders.

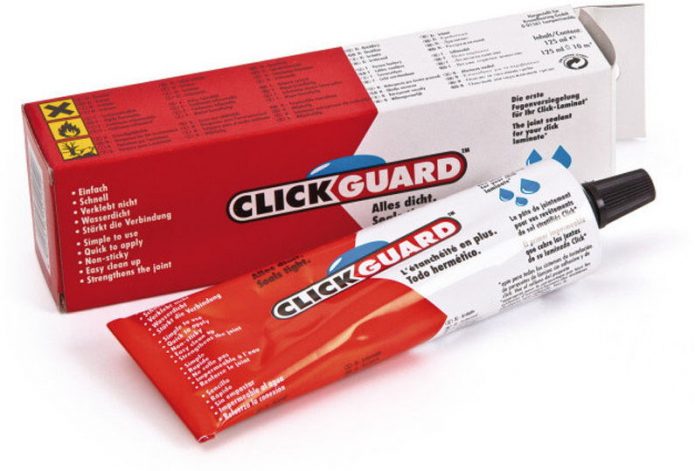

Click guard

A series of sealants from a German manufacturer, characterized by high-quality performance and having a corresponding high cost. The polymer composition completely hardens in a quarter of an hour. Standard consumption is only one pack per 8.0 m cultivated area2.

The ease of use of Click Guard in operation is explained by the presence of a special tip on the tube, so you do not need to purchase additional devices for applying the composition.

Rico Protect Click Grace

The composition of the Swedish manufacturer has excellent physical and technical characteristics and good working properties, it is optimally suited for working with laminated floors of any type, including a premium floorboard. After application, the polymer composition dries quickly enough and provides high protection of the surface, structure and castle system from moisture.

Despite the considerable cost, the composition is very popular. The polymerization time is only half an hour, and the standard flow rate is one package per processing area of 15 m2.

Laminate made in China is no worse than German, but you need to know how not to stumble on a flimsy fake. About how to choose the right material, read the article:https://floor.expertexpro.com/en/pol-pokritiya/laminat/kitajskij-laminat.html.

Quick-Step Seal & Click

The Belgian Quick-Step Seal & Click laminate sealant was developed by specialists to provide the floor surface with long-term protection against moisture and is ideal when using a laminated board in bathrooms. The composition is characterized by elasticity and full transparency, as well as the absence of stickiness.

The composition hardens quickly enough, and the standard gel flow rate from one tube of such a sealant is about 8-10 m² of the treated area.

Soudal

Colored acrylic sealant from Belgium, used to seal cracks, for the restoration of chips, cracks or scratches.It has an affordable cost, has excellent adhesion properties, and the excess applied composition can be easily washed off with water. A definite drawback is the need to purchase a special gun designed for applying the composition.

Acrylic dispersion does not contain solvents; it is produced in the color scheme beech, maple, cherry / cherry, wenge and merbau. Standard consumption is about 10 meters for seams with a width of 0.5 cm.

Masterfix

High-quality acrylic, silicone-based water-based sealant has good adhesion, can be painted, it is very easy and quick to apply, and also maintains plasticity for a long time. The mixture has a high drying rate, so distribution work must be completed within a quarter of an hour.

Available in a volume of 2.8 liters, as well as 280 ml and 600 ml. Russian Masterfix sealant has an affordable price for consumers, is characterized by excellent water-repellent properties and is an ideal option for unprofessional use.

Video: Click Guard Sealing Gel Overview

Instruction for use

Proper use of the sealant for the laminated board is characterized by complete environmental safety of the floor covering, protecting it from moisture in the crevice space between the panels, allows you to disassemble and re-stack the elements and significantly increases the service life of the laminate.

Joint processing strengthens the old flooring and also facilitates the installation of a new laminated board. An important moment of laying is the formation of joints and the process of adhesion of the putty to the side surfaces. It is enough to apply sealant, then wait for the time indicated by the manufacturer of the composition (about a quarter of an hour) and carefully remove the excess with a dry cloth, water or special means.

It will not work to lay the laminate without undercutting, and it is impossible to cut it with bare hands. You can find out about the used power tools for cutting material on our website:https://floor.expertexpro.com/en/pol-pokritiya/laminat/chem-rezat-laminat.html.

Necessary tools

To lay a laminate flooring with sealants, you need to prepare a set of the most basic tools, presented:

- a laminate clamp or a mounting bracket;

- padded plastic or wooden block;

- restrictive wedges;

- rubber spatula;

- drill with a set of drills;

- marking pencil and tape measure;

- hammer or mallet;

- hacksaw.

Some formulations require the purchase of a special gun for applying sealant, but a significant part of the product is available in convenient tubes with a tip. To remove all excess gel, a soft rag or plastic trowel is used, and special formulations are bought.

Preparation of the coating for work

- The coating prepared for application should be clean and as even as possible. Particular attention will require careful sealing of all expansion joints along the walls.

- Using a damp cloth, the entire working surface of the laminate floor is treated.

- Masking tape is glued along the deformation gaps, which will allow the sealant to enter exclusively into the seam space.

- The suture space of the deformation gaps is neatly but carefully filled with sealant from the tube, after which the composition is leveled with a rubber spatula. At the final stage, a strip of masking tape is removed, and excess sealant is removed with a napkin or cloth. It should be remembered that all work with sealants is carried out according to the instructions that are indicated on the package.

Joint sealing technology

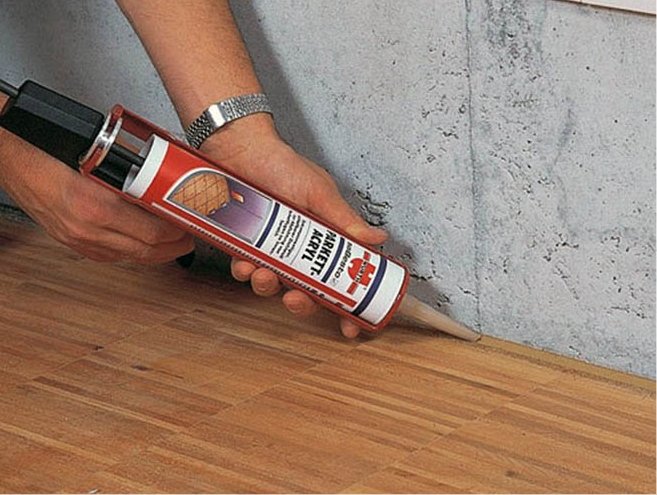

- Sealing joints on a laminated floor with acrylic and silicone compounds is easy to do. Before laying, the panels are treated with gel, which is applied to the upper parts of the ridges, along the longitudinal and lobar side with a continuous layer. In this case, the tube with sealing means must be inserted into the seam at an angle of 45about. It is very important to lay the elements before the water-repellent composition dries.

- After installation, all excess sealant is removed from the surface with a soft rag or plastic spatula. If necessary, solvents suitable for wood or laminate can be used.

Video: Seam Seam Processing

As the work with sealants for laminated boards shows, the use of such compounds for joints of laminate elements in the flooring is quite simple, therefore it is most often performed independently, without the involvement of specialists. Nevertheless, to obtain a high-quality and most durable floor covering that retains its appearance for a long time, it is necessary not only to competently approach the choice of sealant, but also to carry out the correct and accurate installation of all laminated elements.