Warming of a wooden floor: the technology of thermal insulation with expanded clay base of wood

In the fight against cold, in creating comfortable living conditions, any means of reducing heat loss is actively used. Today, the preparation for winter in the house or apartment is carried out thoroughly and involves not only replacing old window frames with energy-saving plastic, wall insulation, but also implies warming the wooden floor. Especially when you consider that heat loss through leaks in the floor covering, door slit, etc. make up almost a fifth of the total expenditure of thermal energy.

The use of new composite materials allows you to create a state of comfort in the room. Especially if heat saving works are carried out in apartments on the ground floors of houses or in private construction.

Expanded clay is one of the options for a sufficiently durable, easy to install, lightweight insulation, specifically for wooden flooring.

Advantages of expanded clay as a heater

Obvious "advantages" of warming a wooden floor with expanded clay:

- Resistant to temperature extremes.

- The air-filled porous structure is an excellent lightweight sound absorber that almost does not create additional load on the foundation.

- Easy to use during installation: in bulk or dry.

- It is made of clay, being an environmentally friendly material.

Attention: due to increased hygroscopicity, expanded clay quickly absorbs moisture in its pores and almost does not give it away. Therefore, mixing it, for example, with concrete as a heater is inefficient. Such a connection causes the exact opposite effect.

What do you need to have in stock?

Increasingly, insulation of a wooden floor with expanded clay is used to expand the living space in an apartment. Expanded clay “conquers” balconies and loggias from the cold, in which you can now be even in winter. It is not difficult to create a favorable microclimate for yourself. It will take all that "nothing":

- a wish;

- basic building skills;

- source materials;

- the most common tool that every owner has: a planer, an electric drill, a shovel, a level, a hammer, a tape measure, a pencil.

Step-by-step technology

The task of warming is reduced to laying a layer of expanded clay between the "rough floor" and the floor covering from boards or parquet.

Attention! The thickness of the insulating material should be designed for the expected dynamic loads during operation, as well as the weight of the screed layer on top.

Stages of work when warming a wooden base:

- Floor preparation. The reconstruction of the old wooden coating requires its complete dismantling up to the very lags - the main fixing structures. If necessary, worn boards are replaced; the base is strengthened.

- Inspection of the base. Then sanding is carried out, the surface is compacted for waterproofing.

- For insulation under expanded clay, you can use liquid mastic or parchment.

- The floor is evenly divided into zones fenced with slats of a certain height. Expanded clay is covered with a layer of 10 cm.

- Expanded clay aggregate is compacted very carefully by tamping. It is important that the fragile granules do not break. To better fill the voids, in order to avoid subsidence, it is recommended to mix different fractions of expanded clay.

- Hydro-vapor barrier is laid on top of the prepared frame.

- Installation of the main wooden coating completes the insulation process.

By the way: beams and logs under a wooden coating act as a kind of “cold bridges”. They should not be too high (so as not to “take” heat), but not thin (so that the structure is stable). Just in this case, the rule of the “golden mean.

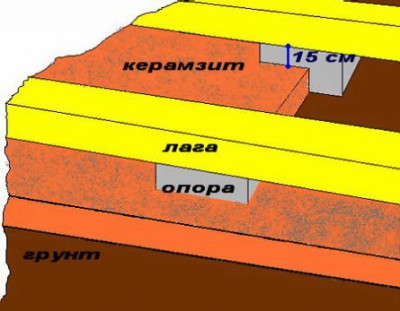

If it is necessary to insulate a wooden floor located directly on the ground, the technology is slightly different:

- First, gravel is added. It retains cold, disperses moisture;

- sand is poured on top and compacted;

- expanded clay is poured onto this “double cake” and fixed with a metal mesh;

- with a layer of concrete on top, all layers are bonded, a wooden coating is laid on this surface.

A simple, relatively cheap and affordable way to create a comfortable stay using expanded clay for warming a wooden floor not only reduces heat loss in the house. High-quality insulation is a guarantee of a healthy lifestyle in it.

4 comments