Expanded clay as a heater - floor insulation expanded clay

In a private house, the issue of floor insulation at all times was relevant and people, trying to solve it, used different building materials to maximize thermal insulation of their house. But finally, the ideal insulation was invented, which meets all the norms and standards of residential premises - this is expanded clay. What do we know about him? Expanded clay is an environmentally friendly porous material, which is obtained by the method of expansion of low-melting clay rock. It is used for insulation and soundproofing of residential buildings and industrial buildings.

The main characteristics and advantages of expanded clay

- Excellent heat and sound insulation.

- High strength.

- Fire resistance.

- Frost resistance.

- Environmental friendliness and durability.

The regime and method of processing clay determine one of the most important characteristics of expanded clay - a bulk density or bulk density, which ranges from 200 ÷ 400 kg / m³.

Depending on the density of the substance, its thermal insulation ability is determined. But in the production process to achieve the release of the ideal expanded clay granules is a difficult task, therefore it is divided into fractions:

- 5-10 (expanded clay sand);

- 10-20 (expanded clay crushed stone);

- 20-40 (expanded clay gravel).

Expanded clay as a material for floor insulation

Expanded clay is insulated with special technology, observing that any floor, even the coldest, will become the warmest and most comfortable. The floor, as you know, has the largest load in the room, so when it is insulated, it is necessary to calculate the correct thickness of the insulation layer so that over time it does not sag and deform the floor surface.

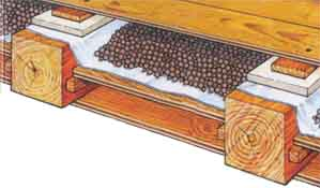

When laying any type of floor, the first thing to do is to cover the waterproofing layer, in the case of expanded clay it is more than relevant. Since this material is porous, it easily absorbs moisture, which is fraught with unpleasant consequences, so the waterproofing device is laid first. Then a heat insulator is placed on top of it with a uniform ball.

To achieve perfect uniformity, before filling expanded clay, you should put the so-called "guiding pendulums", which are the level of the future floor. The first “guiding pendulum” is installed at a distance of 20-30 mm from the wall, the subsequent ones are mounted parallel to the first and between each other at a distance depending on the length of the rule by which the screed will be aligned.

Expanded clay as a floor insulation is effective if its granules are heterogeneous, that is, the size of the granules must be different so that smaller granules fall into the space formed by large granules and fill it. If, for example, we take expanded clay gravel, then no matter how you tamp it, the space between the granules cannot be completely removed and the floor will “fail” in future operation.

Therefore, the most acceptable option is a mixture of all three fractions of expanded clay. When the expanded clay layer is laid, it should be carefully tamped so that the resulting air sacs disappear completely.

Floor screed on laid expanded clay

An important role is played by the screed in the floor insulation; it provides reliable fixation of the insulation and top waterproofing. Before applying the final top layer of the screed, it is necessary to fill in another intermediate layer, the so-called "fixation".To do this, mix cement with water. The result is a uniform suspension, not very liquid and not very dry, that is, of such a consistency that it can be poured a layer of expanded clay.

This action is performed so that the cement slurry gets into the remaining empty spaces, displaces the air and fills them. As a result, after the fixation layer has dried, a monolithic expanded clay floor will be obtained, which will not be afraid of moisture or large loads. We can safely say that such a floor can withstand even a small earthquake. The final layer of the floor will be a screed, which finally levels the floor and makes it ideal for further flooring.

Solution for screed on expanded clay insulation

But the screed also needs to be able to “cook”, because the reliability of the entire future sexual structure depends on its reliability. First of all, you need to choose the right, or rather, high-quality materials - this is cement and sand, on the proportional ratio, which determines the hardness and elasticity of the screed. Naturally, the more cement, the final structure will be stronger. But here it’s worth showing prudence, because you just can’t do it in time, use the entire solution, because with a high content of cement it dries quickly.

The most optimal ratio of cement and sand is considered to be 60% to 40%, respectively. Water is added "by eye", approximately 10-20% by weight of the dry mixture. After that, all components are thoroughly mixed, and the resulting solution is poured onto a monolithic expanded clay layer. Then, by means of a large spatula, about 100 cm long, the solution is evenly leveled to form the so-called tightening mirror.

After hardening, the insulated floor is ready for further improvements. If all of the above conditions are met, then the result is a reliable, warm, comfortable floor.

4 comments