Infrared underfloor heating under linoleum: detailed step-by-step installation instructions

Film options for floor heating are characterized by a mass of positive consumer and technical qualities. They form the most favorable temperature background. They do not require binding devices, are easy to install, and work perfectly in tandem with almost all coatings. You can arrange an infrared warm floor under linoleum with your own hands, if you know the rules and the subtleties of installation.

Content

Infrared floor paired with linoleum

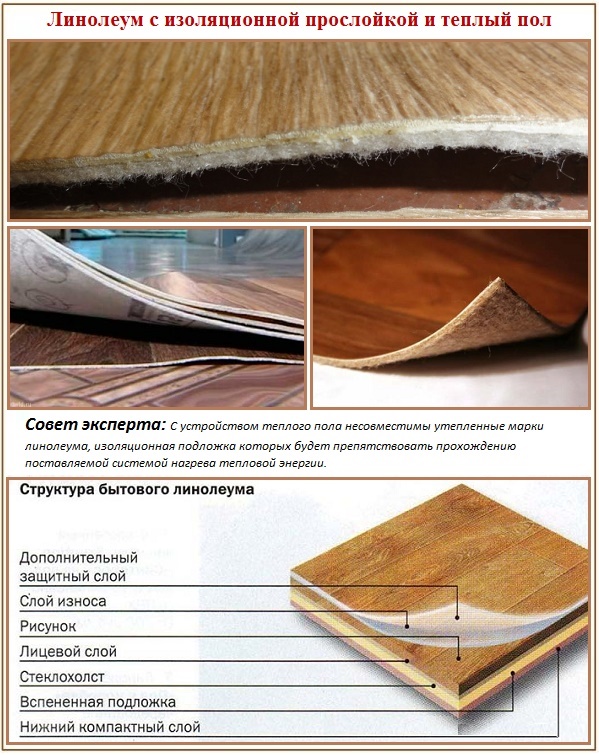

Affordable prices do not prevent linoleum from being a rather “capricious” coating. From heating, budget brands can warp, stretch or sit. Cheap material can release toxins when the temperature rises. Dear representatives with an insulating substrate, all attempts of heat to pass through them and reach the feet of the consumer are nullified.

Coating suitable for IR heating

Before the appearance of film floors, the proximity of linoleum to “warm floor” systems required serious technical tricks or was excluded outright. Direct cooperation with electric or water circuits was allowed only to marmoleum - natural linoleum. Although it has serious claims for heat retention.

With the introduction of infrared heating systems, linoleum still joined the ranks of materials that make it possible to arrange a “warm floor” underneath. In addition, manufacturers of numerous types of coatings made significant changes to the formula, which ensured resistance to temperature increase up to + 35ºС and dimensional stability.

However, when choosing linoleum for laying on top of even an infrared heating system, labeling should be carefully studied. It should indicate the compatibility of the material with electric underfloor heating. If the manufacturer's assurances turn out to be false - the coating will deteriorate from contact with the heating system, money must be returned for it.

By the way, no one compensates you for the losses that occurred due to a violation of the technology for installing a film floor. They will not return the lost funds if the conditions for installing linoleum on top of infrared heating were not met. Therefore, it is worthwhile to familiarize yourself with the technological requirements for the construction of film systems.

Linoleum compatible underfloor heating

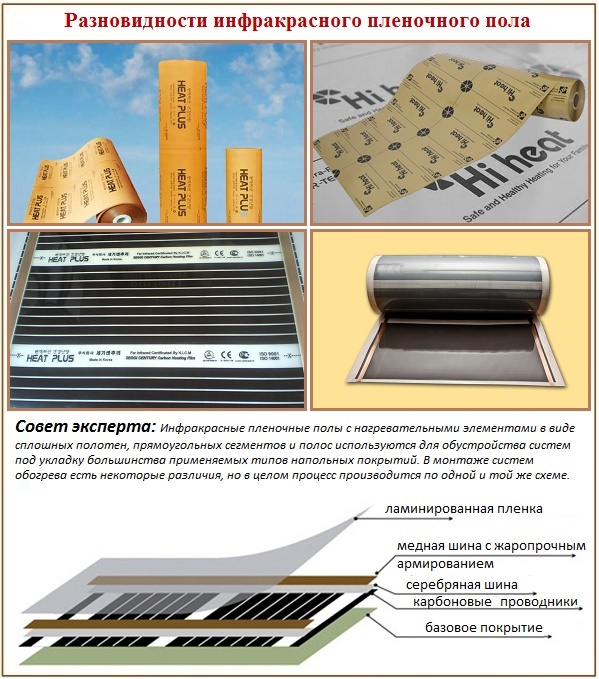

The consumer is now presented with a wide variety of film heating systems.

There are options with a solid carbon heating element or with rectangular large segments. With their help, large health centers and public organizations are equipped. Mount similar systems mainly in the screed.

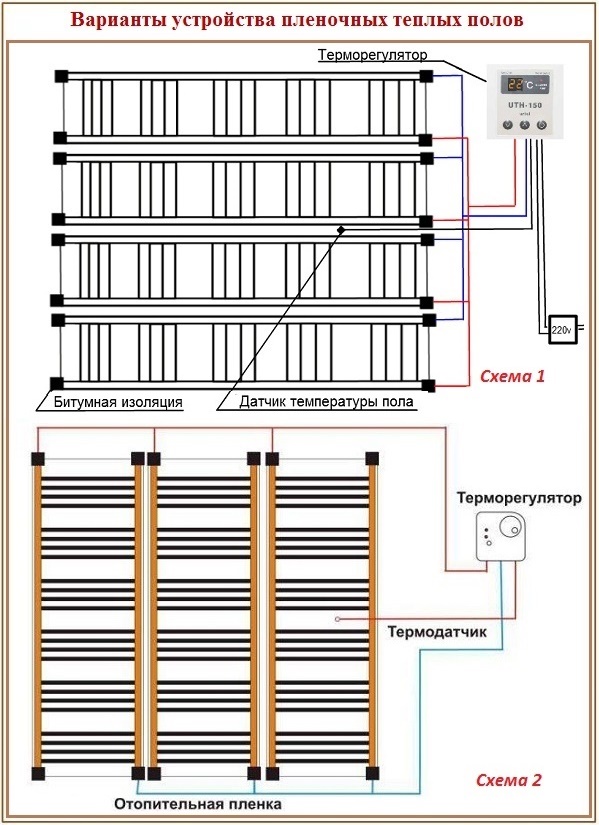

In everyday life, the so-called striped films are most often used. The heat-generating carbon in them is located in transverse stripes. The edges of the strips on both sides are clamped with copper and silver tires, which communicate energy to the elements, grounding and suppressing sparking.On the outside and inside, infrared heating systems are coated with a thin polymer film.

Depending on the function assigned by the manufacturers to copper and silver tires, film floors are laid up or down with the side of the copper strip. This technical point is indicated by the manufacturers in the instructions, it should be closely monitored before laying a particular brand of infrared film.

Otherwise, the installation processes of all varieties of infrared warm floors are similar. They are carried out in stages with mandatory preliminary calculation, design and preparation before construction.

All types of film heating before laying linoleum require the installation of a protective layer of plywood, hardboard sheets, GVL or fiberboard with a thickness of 3-5 mm.

The nuances of design and calculations

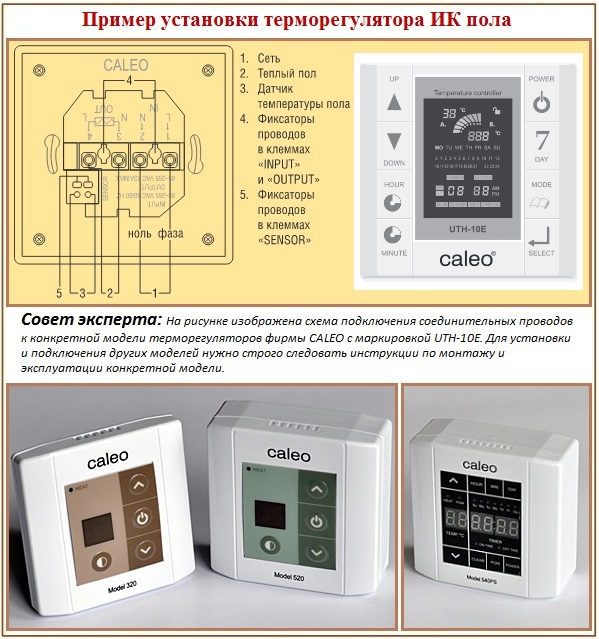

Let us analyze the calculation procedure using a specific example of the device of a film system of the Caleo brand produced for laying linoleum. We take into account that this type of coating is mainly used in the arrangement of bathrooms, corridors, kitchens of high-rise and low-rise buildings, reserved for stairwells of private buildings and other similar premises under the winter garden.

The standard layout of the layers in the pie

The cake of the warm floor, the floor linoleum will include five obligatory layers, these are:

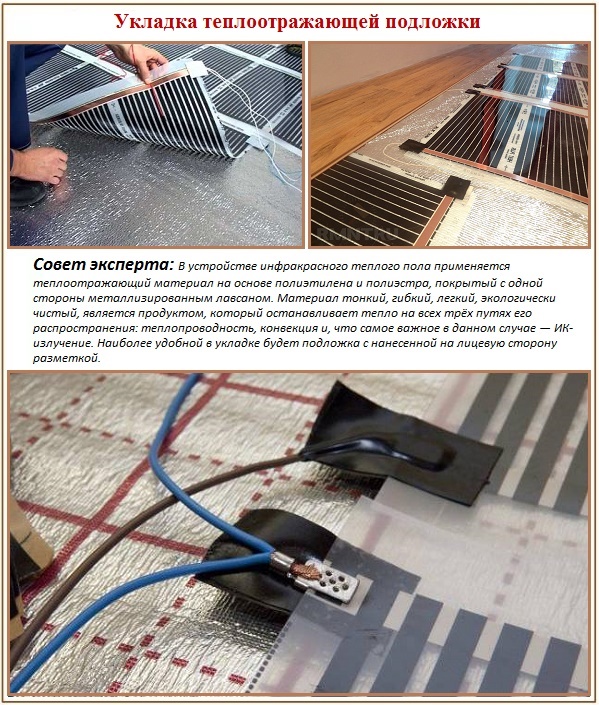

- Heat-reflecting substrate. The use of materials such as Isolon or Infralex is recommended. The use of thermal insulation with a polypropylene or lavsan metallized outer shell is allowed. It is forbidden to lay materials with an aluminum foil base under the IR floor.

- Infrared film floor. The system includes longitudinal stripes with carbon strip spraying, at least one temperature sensor and a temperature controller. The film system towels are connected to the power source in parallel using the terminals and wires included in the factory kit.

- Polyethylene. Stacked on top of the heating system after assembly and inspection. It plays the role of waterproofing infrared electric floors. The maximum thickness is 2 mm.

- Protective hard layer. It is made of plywood, hardboard or similar material. Required for underfloor heating with a flexible topcoat.

- Linoleum. Only brands compatible with electric underfloor heating are suitable.

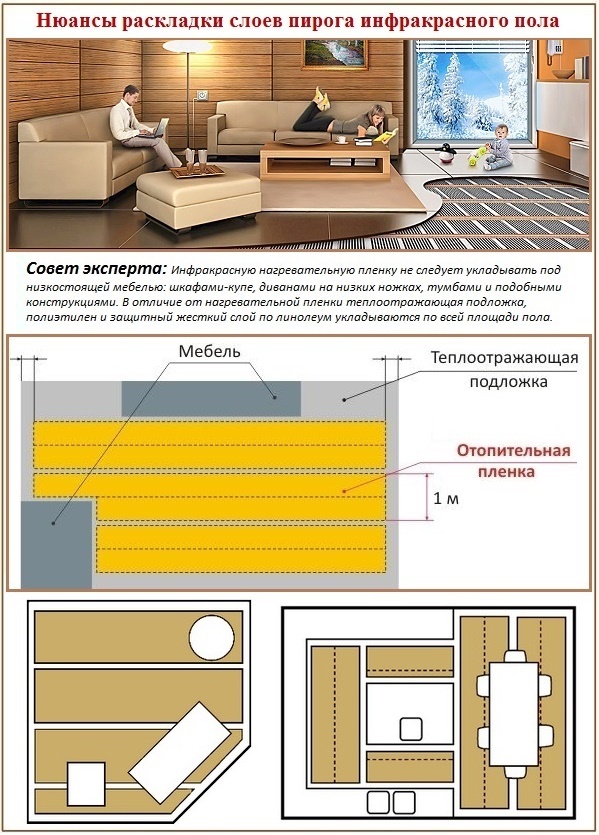

When designing, it is necessary to take into account that the directly film-type infrared-type heat-insulated floor is not placed under furniture without legs or with low legs. It is unreasonable to heat objects that do not need heat supplies, but are able to consume an impressive amount of it.

But the insulating substrate and the rigid layer are arranged over all areas of the room in order to withstand a uniform height level of the floor. Waterproofing, in spite of its insignificant thickness, is laid similarly over the entire area in order to prevent the penetration of water into the electrical system during wet cleaning.

Styling

For competent design, it is necessary to draw up a plan or elementary diagram with scaled real dimensions. Self-made project will help to correctly calculate the footage of thermofilm and related consumables.

The sheets of the heating system, waterproofing and heat-reflecting substrate are fixed to each other with single or double-sided tape.

In addition to these nuances, design must take into account that:

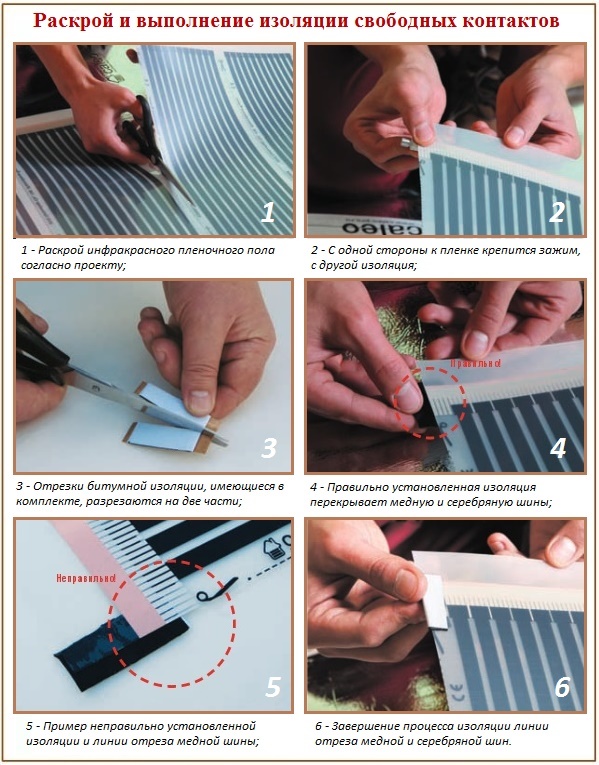

- Cutting IR thermal film is possible only according to the lines specified by the manufacturer. Cutting at an angle and the formation of curly panels are not allowed.

- Laying is done in parallel stripes. It is not allowed to overlap one panel with another.

- A gap of at least 3 cm should be left between the low-standing furniture and the film floor. An indent should be left between the edge of the panels and the walls: it will provide heat dissipation in case of overheating.

- It is recommended to lay open strips of thermal film with a lateral overlap so that there is a gap of at least 1 cm between the copper tires of adjacent panels. The indicated location will ensure uniform floor heating.

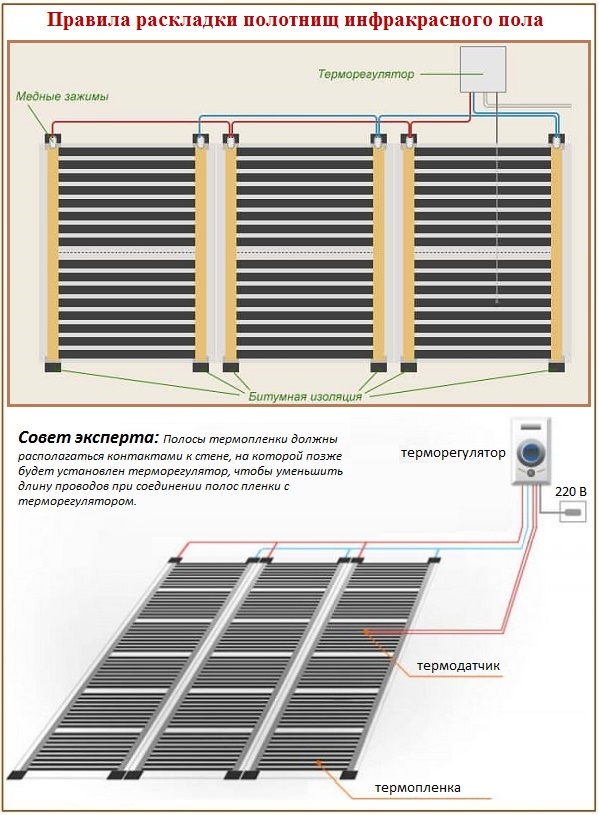

- The heating system towels should be as long as possible in order to minimize the number of connection points.

- Connection points must be located on the side of the wall on which the thermostat will be installed. Due to this, the footage of the wires required for connection will be significantly reduced.

- The wiring must be thought out so that their main array is located under the baseboard.

It should be remembered that when cutting the film floor into short segments up to 1 m long, additional insulation and the use of additional terminal clamps will be required. Those. You will have to purchase a mounting kit in addition to what is included in the package.

In advance, you need to determine the type of temperature controller, which can be built-in or overhead. To install the built-in variety, you will need a corrugated polymer pipe, used when laying in the line, for open wiring a plastic cable channel is required. For large areas or floors in adjoining rooms, additional temperature sensors may be required.

Additional electrical and insulation

If it is planned to connect several sets of a film floor to one thermostat, then the power consumption is determined by adding the capacities of all the elements. The wire for connecting parts of the infrared floor to the thermostat is selected in accordance with the result.

You must purchase the cable necessary to connect the thermostat to the mains, as In the factory kit, a wire is provided only for connecting the film heating to the thermostat itself. You need to select it in accordance with the maximum power required for the system functionality.

Do not forget that electric heat-insulated floors are arranged with the mandatory inclusion of an RCD with a 30 mA actuation parameter acting on a 100 ms wiring. A circuit breaker of category C is required, designed to protect a live branch of 10 A.

If other electrical appliances are still connected to the automatic protection devices, their power should be taken into account in the calculations. For a film floor consuming 2 kW or more, it is recommended to arrange a separate branch with its own machine.

Installation of a film floor cake

Suppose that after design and calculations we purchased a set of infrared floors with the most suitable width and the missing pie components in the required quantity. It remains to find out in what sequence and how to correctly lay a film infrared floor under the finish linoleum.

Laying the substrate and heating system

In the first cases, a heat-reflecting substrate is laid, the stripes of which are glued into a single cloth with tape. In large rooms with an area of more than 20 m3 it is recommended to connect the backing with double-sided adhesive tape in order to exclude its movement relative to the subfloor. Instead of double-sided tape, fixing with a construction stapler is suitable.

Next, we proceed to the stage of construction of the film floor:

- We cut the thermal film according to the instructions of our own project.

- We try on the "pattern" to the place of future styling. If necessary, tune, slightly change the width of the side padding and the gap between the walls and the heating system.

- Having decided on the position of the individual panels, we proceed to the assembly of the warm floor.

- We lay the panels of the warm floor strictly with the copper bus down.

- We isolate the exposed contacts of the panels from the edge opposite the connection side. Just glue the areas of the silver and copper trimming with bitumen tape so that contacts with the environment of both metal strips are completely excluded.

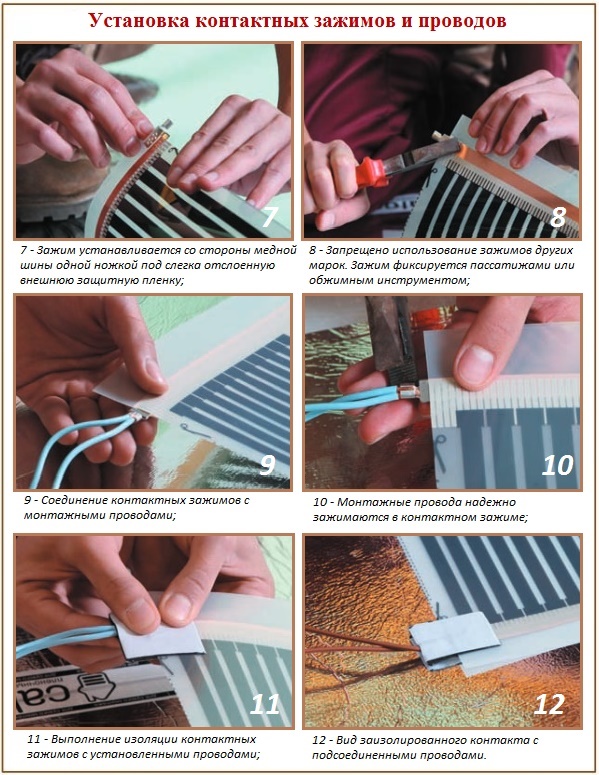

- We install contact clamps on the current supply strip of the thermal film. To do this, slightly peel off the polymer shell to introduce one side of the clamp under it, and place the second side on top of the copper busbar.

- After checking the correct installation, with force we fix the clamp with pliers.

- In accordance with the described scheme, we equip with clamps all the contacts of the film floor from the side of the connection to the thermostat.

- We connect the strips with wires so that the phases are connected to the phases, and zeros to zeros. To do this, the package includes wires of two different colors. From the connected ends of the wire, remove the insulation and put them in two or one at a time according to the design scheme in the clamp.

- The connection points reinforced with pliers are insulated with two pieces of bitumen tape on both sides.

- We connect the circuit to the thermostat.

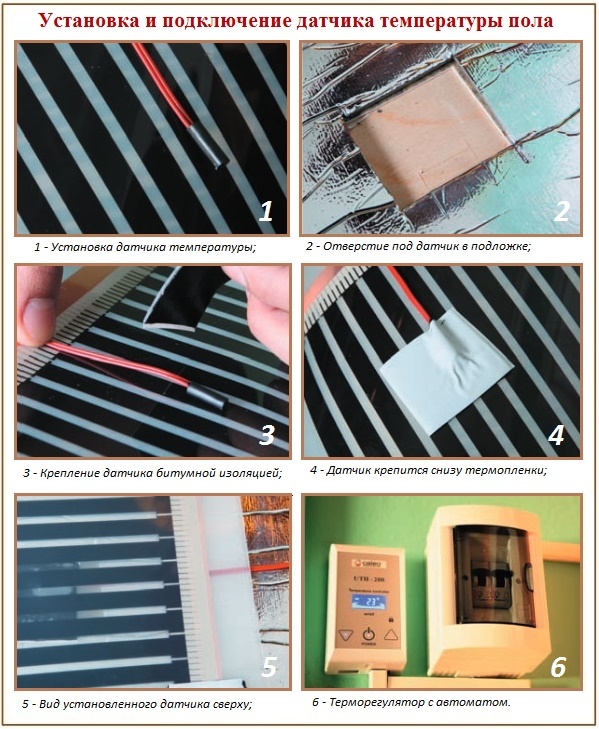

- In a convenient place, install the temperature sensor with a convex side down and connect it to the thermostat. Paste it on the bottom with bitumen tape. The sensor of the system under the linoleum needs to be positioned so that movement on it is excluded or was the least intense.

The infrared floor heating system has been assembled, and the final work on arranging the contour and laying the finishing material has remained.

Final stages of the IR floor device

In order for individual parts of the system not to stand out under the coating and not to undergo undesirable mechanical stresses, they should be “drowned” in the insulating substrate. To do this, in the heat-reflecting layer we cut out “windows” and “trenches” under all convex details: temperature sensor, contact clamps and wire routes.

Next, we test the work of the film floor by connecting power to it. On the thermostat for a control check, set the value to + 30º C. The operation of each contact and the safety of the insulated points are checked with a screwdriver indicator or a similar device. After verifying the normal functionality of the infrared system, we cover it with polyethylene and lay a hard protective layer.

If necessary, a hard layer assembled from plywood, gypsum fiberboard, hardboard, etc. fasten to the rough base with self-tapping screws so that the fixation points pass through the transparent edge of the film floor. It is more convenient to work with material with a docking chamfer along the edge.

Do not forget that the infrared system needs to “breathe”. Therefore, along the perimeter of the hard flooring, a gap of 1-2 cm should remain, which after the finish coating is closed with a skirting board.

To the constructed and fixed rigid base, we glue the double-sided construction tape used in laying linoleum, and we lay the finish coating itself.

Video recommendations for the installation of IR floors

The video demonstrates the essence of the infrared warm floor device for further laying of linoleum:

The calculation scheme and one of the options for laying an infrared film floor:

Review of film heating systems offered for sale, tested in practice:

The rules for the construction of infrared floor heating systems with linoleum as a topcoat are not too many. However, each of them must be observed in the name of a long service of the film version. It is worthwhile to use a thermofilm of a verified manufacturer, and select components only of the same brand.

2 comments