Choose parquet lacquer and understand how to coat parquet with varnish

Parquet is appreciated not only for its aesthetic beauty, but also for environmental friendliness, practicality and durability. Such a coating is a favorite among people who receive aesthetic pleasure from natural solid things, creating unique comfort and coziness. However, like all floor coverings, parquet tends to get dirty.

To protect and protect it from the harmful effects of dirt and dust, it is necessary to create a protective coating. It is not advisable to use paint for these purposes. She will hide all the beauty of natural material. Parquet varnish will help protect the coating from pollution and preserve the wood texture. It is only necessary to make the right choice and adhere to the technology when applying the composition to the coating. About how to do this, and will be discussed.

Varieties of varnishes for parquet

Many people think, buying parquet lacquer how to choose the right composition, so as not to spoil the coating. It is important not only to choose a quality product, but also to use it skillfully. It is difficult to say which parquet varnish is better, it all depends on the purpose of the room. Of the wide variety of products offered, three categories of varnishes can be distinguished:

- water soluble;

- anhydrous, based on oil resins;

- acid curable.

Type # 1 - Water Soluble Varnish

The basis of water-soluble varnish is water. It has virtually no solvents. It is environmentally friendly and safe. Since this varnish is odorless for parquet, it can be used in rooms for children and allergy sufferers. It is neither toxic nor combustible. However, water-soluble varnishes are less resistant and are afraid of low temperatures. When falling between the parquet strips, the composition glues them together, so it is recommended to use a primer before applying such varnishes.

Type # 2 - Anhydrous Option

Anhydrous varnishes include solvent-based alkyd resins. They are extracted from wood or linseed oil, which contributes to the deep penetration of the composition into the structure of the tree. Alkyd varnish can be used in rooms with differences in humidity, temperature and vibration loads.

It is good for parquet from “finicky” wood species. But alkyd varnish is more sensitive to drying conditions. For hardening it needs an influx of fresh air and a stable temperature. In addition, the consumption of varnish for parquet per layer should not exceed 120 grams per 1 m². An excessively thick coating may frown.

Another representative of anhydrous varnishes is polyurethane. Due to its wear resistance, it is successfully used in rooms with enhanced operation. And also with the possibility of chemical exposure. Polyurethane varnish must be protected from water during the drying process. Subsequently, it is less susceptible to moisture and temperature changes.

Type # 3 - Acid Curable Varnish

Acid-cured varnishes are considered the most resistant of similar coatings. They are used in rooms with heavy loads on the surface. Since this is a two-component parquet varnish, it is mixed with an hardener (10 to 1) containing acid before use. Therefore, the time of use of such a composition is limited to 8 hours.

Since varnish emits harmful fumes during application, it is recommended to use personal protective equipment. And the room in which the work is carried out should be well ventilated.

Technology for coating parquet lacquer

Well, now let's move on to the process itself. It is desirable that the temperature in the room during work was in the range of 12-25 degrees. It is at this temperature that the varnish lays well and dries.

Preparatory work

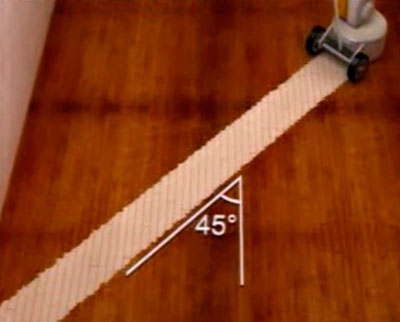

Before parquet varnish to cover it must be prepared. A prerequisite for preparing the base for applying varnish is grinding. It must be carried out in the right direction. With the "deck" location of the parquet, grinding is carried out at an angle of 45º to the planks.

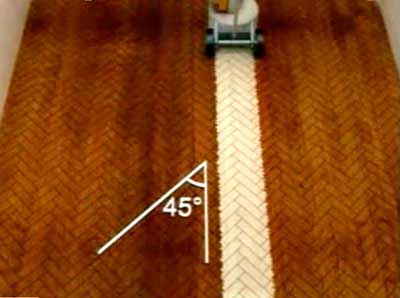

The herringbone planks are ground along the pattern.

If the old parquet with defects must be putty. It is not always possible to choose a composition suitable for color. Therefore, for filler use sawdust remaining after grinding, mixed with liquid based on nitrocellulose. The grinding process lasts until the upper tarnished layer is completely removed. Then the parquet is cleaned of debris and dust.

Upon completion of the preparatory work, the floor should have a natural "vibrant" color. If the parquet is coated with wax, it must be removed with white spirit before sanding. Otherwise, it will contaminate the sandpaper.

Parquet lacquering

After thorough preparation of the base, the parquet is directly painted with varnish. It can be applied with a roller, brush, spray gun. To apply the composition with a spray gun, the varnish is diluted with white alcohol. Dilution to 10% of the varnish volume is allowed.

After the first layer has dried, the parquet is treated with a grinder with fine-grained paper. They clean the surface and apply a second layer. Application from 3 to 5 layers is allowed. The average consumption of varnish is 0.8-1 liters per m².

Parquet care after varnish

Even if you used quick-drying varnish for parquet, it is advisable to protect the floors from excessive exposure for the first time. The service life of the updated parquet depends on how carefully the handling of the varnish is in the first days. Do not immediately put carpets on the floor. Wait a couple of weeks. To protect the flooring, attach felt pads to the furniture legs. Wherever possible, place rugs under the interior. It is advisable to treat the surface with the composition once a year to revitalize the lacquer coating.

Video with an example of work

If you are still considering what varnish to cover the parquet, first of all decide on the purpose of the room and the possible load on the base. Anhydrous alkyd-polyurethane varnishes are wear-resistant, but require special conditions when dried. Acid-cured varnishes are resistant, but contain harmful substances. Water - environmentally friendly, but less resistant to abrasion and temperature changes. Decide what is more important for you.

2 comments